Backlight module, over-temperature protective circuit and over-temperature protective method

A technology of over-temperature protection and backlight module, which is applied in the direction of instruments and static indicators, etc. It can solve the problems of affecting the user's visual perception, affecting the conversion efficiency of DC-DC converter 110, backlight flickering, etc., to reduce the temperature and reduce the current , the effect of a simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

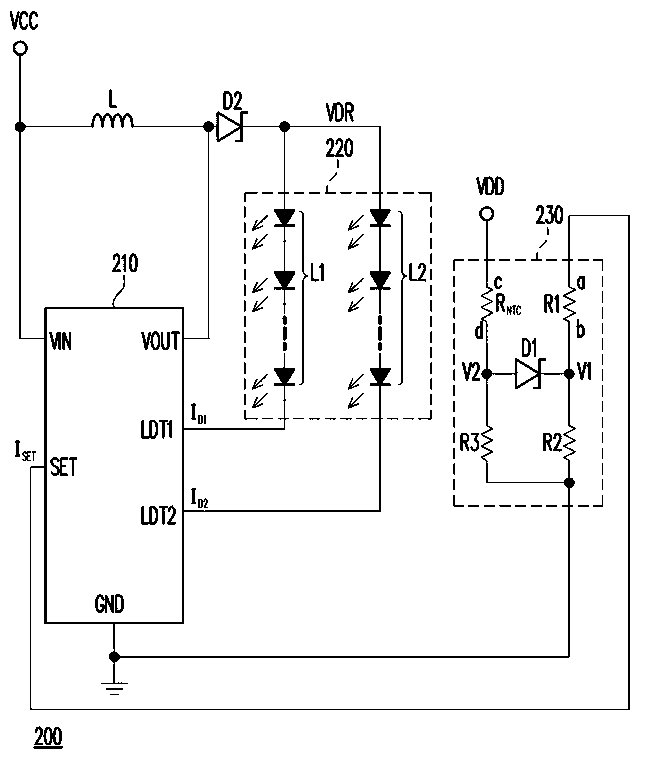

[0050] figure 2 It is a system diagram of a backlight module according to an embodiment of the present invention. Please refer to figure 2 , in this embodiment, the backlight module 200 includes at least a light source driver 210 , a light emitting component 220 and an over-temperature protection circuit 230 . The light source driver 210 has a voltage input terminal VIN, a voltage output terminal VOUT, a ground terminal GND, a current setting terminal SET and at least one light source drive terminal (such as LDT1 and LDT2), wherein the number of light source drive terminals is determined by the circuit structure of the light emitting component 220.

[0051] In the light source driver 210, the voltage input terminal VIN receives the system voltage VCC, the voltage output terminal VOUT outputs the driving voltage VDR to the light emitting component 220, and the current setting terminal SET receives the set current I SET , the ground terminal GND is coupled to the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com