Design method for molded surface of automobile cover part die based on molded surface deformation compensation

A technology for automobile cover parts and mold profiles, which is used in calculations, special data processing applications, instruments, etc. to ensure molding accuracy, reduce manual grinding time, and speed up the design process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The method for designing the mold surface of the automobile panel part based on the surface deformation compensation of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

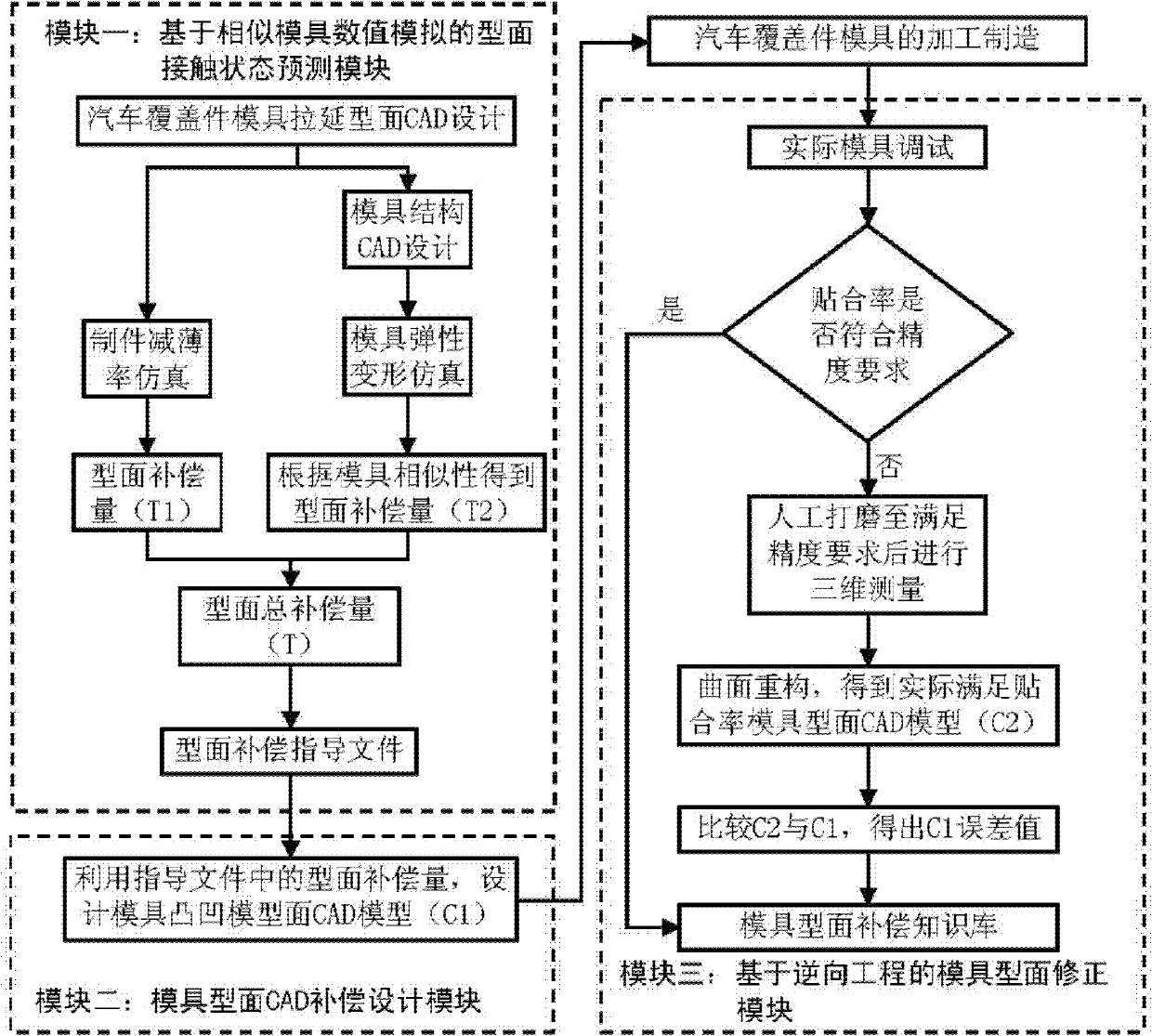

[0036] Such as figure 1 As shown, the design method of the automobile panel mold surface based on the surface deformation compensation of the present invention includes: the prediction of the surface contact state based on the numerical simulation of similar molds, and the output of the mold shape based on the thinning rate of the workpiece and the elastic deformation of the mold. The first stage of the surface compensation guidance document; on the basis of the guidance document, use CAD software to design the mold compensation surface, and the second stage to output the CAD compensation surface; use the method based on reverse engineering to output the actual mold surface after mold repair The third stage.

[0037] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com