Dry-type paved geothermal floor board

A geothermal floor and dry-type technology, applied in the field of building decoration materials, can solve the problems of short heat conduction path, long heat conduction path, and low thermal efficiency, and achieve the effects of short heat conduction path, uniform heating, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

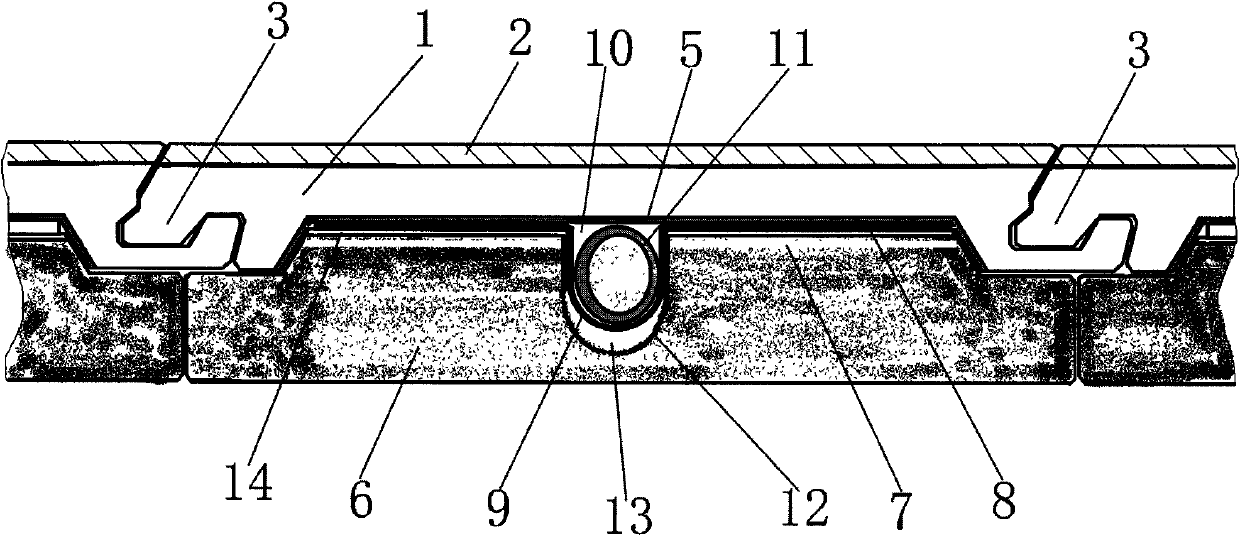

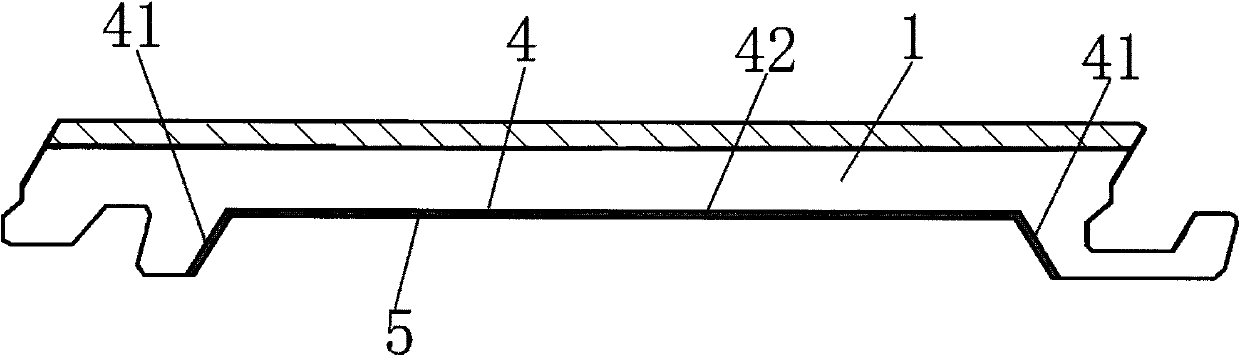

[0022] Embodiment 1: as figure 1 As shown, the upper surface of the substrate 1 is provided with a decorative surface layer 2, the decorative surface layer 2 is a thin plate attached to the substrate, and both sides of the substrate 1 are respectively provided with locks 3 that can cooperate with adjacent substrates, as shown in FIG. figure 2 As shown, the lower surface of the substrate 1 is formed with an upward concave groove 4, the depth of the groove is 1 / 2 of the thickness of the substrate, the groove 4 includes two sides 41 and between the two sides 41 and with the substrate 1 The upper surface is parallel to the upper bottom 42, and the two sides 41 are inclined downward and outward from the two sides of the upper bottom 42. The surface of the groove 4 is attached with an upper heat conduction medium layer 5 made of aluminum alloy material, and the upper heat conduction Dielectric layer 5 covers the surface of upper bottom 42 and both sides 41, such as figure 1 As sho...

Embodiment 2

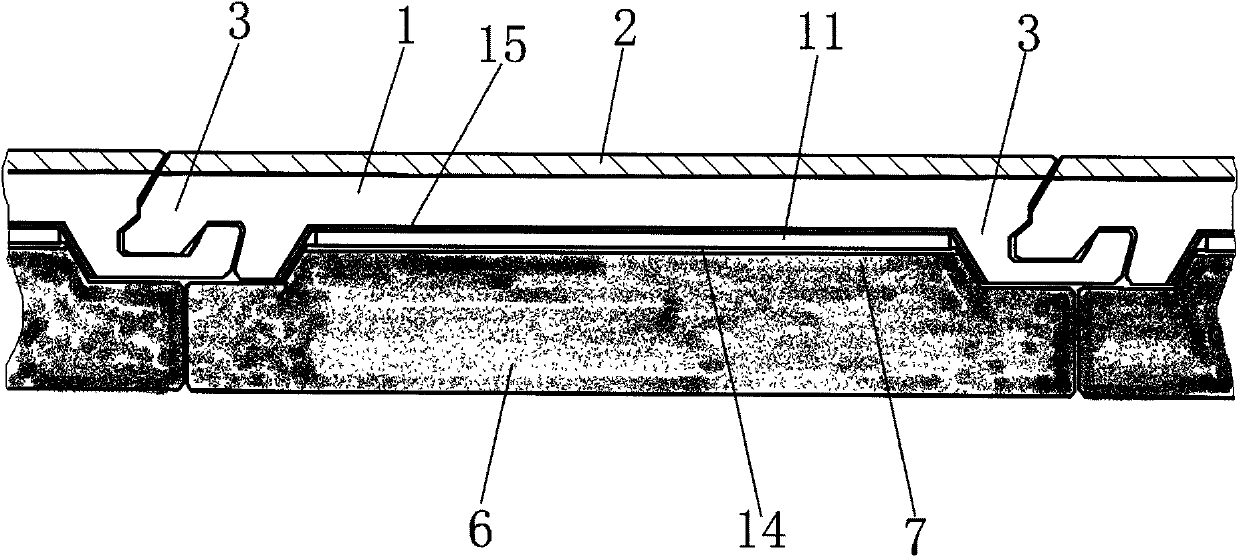

[0024] Embodiment 2: as image 3 As shown, the upper surface of the substrate 1 is provided with a decorative surface layer 2, the decorative surface layer 2 is a thin plate attached to the substrate, and both sides of the substrate 1 are respectively provided with locks 3 that can cooperate with adjacent substrates, as shown in FIG. Figure 4 As shown, the lower surface of the substrate 1 is formed with an upward concave groove 4, the depth of the groove is 1 / 2 of the thickness of the substrate, the groove 4 includes two sides 41 and between the two sides 41 and with the substrate 1 The upper surface is parallel to the upper bottom 42, and the two sides 41 are inclined downward and outward from the two sides of the upper bottom 42. The surface of the groove 4 is attached with a heat-conducting medium layer 15 made of aluminum alloy material. The upper heat-conducting medium Layer 15 covers the surfaces of the upper bottom 42 and the two sides 41, such as image 3 As shown, t...

Embodiment 3

[0026] Embodiment 3: as Figure 5 As shown, the upper surface of the substrate 1 is provided with a decorative surface layer 2, the decorative surface layer 2 is a thin plate attached to the substrate, and both sides of the substrate 1 are respectively provided with locks 3 that can cooperate with adjacent substrates, as shown in FIG. figure 2 As shown, the lower surface of the substrate 1 is formed with an upward concave groove 4, the depth of the groove is 1 / 2 of the thickness of the substrate, and the groove 4 includes two sides and is located between the two sides and is connected to the upper surface of the substrate 1. Parallel upper bottom, the two sides are obliquely downward and outward from both sides of the upper bottom, the surface of the groove 4 is attached with a heat conduction medium layer 15 made of aluminum alloy material, and the heat conduction medium layer 15 covers the upper bottom and On both sides of the surface, the bottom of the base plate 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com