Later-stage processing method of fabric and special equipment thereof

A technology of special equipment and processing methods, applied in the processing of textile materials, textile and papermaking, fabric surface trimming, etc., can solve the problems of inability to open and flatten, unable to enter the drying tunnel in the weft direction, and unpredictable dimensions in the weft direction. Achieve the effect of avoiding uneven feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

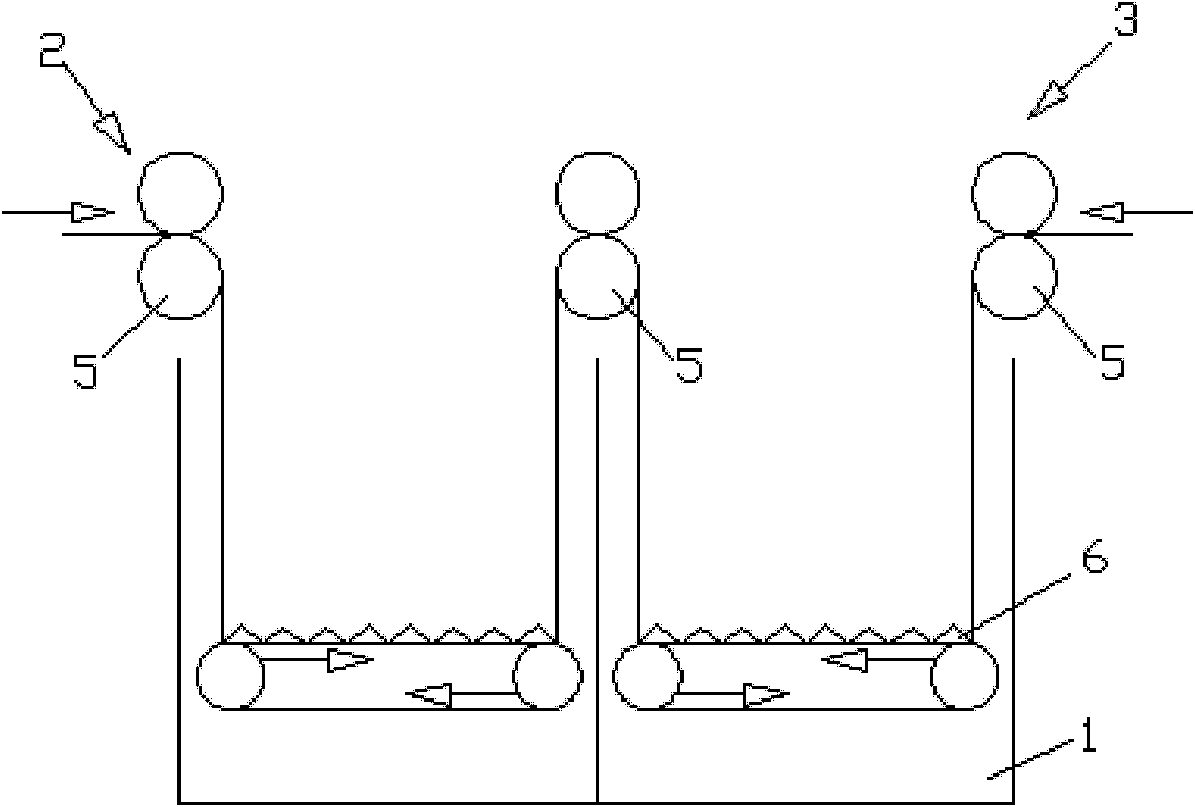

[0039] See figure 1 , what the equipment of this embodiment adopts is single-cylinder to carry out the treatment with water, and overall equipment comprises cylinder body 1, cylinder inlet device 2, cylinder outlet device 3, expansion device, ironing machine 4, transmission chain 6, sliding pressure roller 7 .

[0040] The cylinder inlet and the cylinder outlet of the cylinder body 1 are respectively provided with a cylinder inlet device 2 and a cylinder outlet device 3; the cylinder inlet device 2 and the cylinder outlet device 3 are respectively two pressure rollers 5 arranged up and down and a driving roller 5; the pressure water roller 5 of the cylinder discharge device 3 is a sponge water absorption roller; the ironing machine 4 includes a first cylinder 41 and a second cylinder 42 with adjustable gear ratios; It is arranged on the conveyor belt at the feeding port of the first cylinder 41 of the ironing machine 4 . Transmission chain 6 is arranged on the bottom of cyli...

Embodiment 2

[0043] See figure 2 , This embodiment is basically the same as Embodiment 1, except that it also includes two pressure water rollers 5 arranged up and down above the sub-axis in the cylinder body 1 . This single cylinder with water treatment can be merged by existing 2 common single cylinders, also can be to increase pressure water roller 5 in the middle part of longer single cylinder, can handle longer cloth 8 like this.

Embodiment 3

[0045] See image 3 , the equipment of this embodiment uses a plurality of cylinders 1 to carry out water treatment, and the rest of the equipment is the same as that of Embodiment 1. Three cylinders 1 are shown in the figure, and the cylinder inlet and outlet of each cylinder 1 are respectively provided with a cylinder inlet device 2 and a cylinder outlet device 3 , and a circulating transmission chain 6 is arranged at the bottom of the cylinder body 1 . The pressure water roller 5 of 2 cylinder outlet devices 3 of each cylinder inlet device all uses sponge suction roller, can obtain better coloring or cleaning effect like this.

[0046] The continuous fabric is treated with water in multiple cylinders, and the cloth head of the fabric 8 is smoothly passed through the middle of the two pressure rollers 5 at the inlet of the first cylinder body 1, and the power device of each pressure roller 5 is started. Set the speed ratio of each transmission chain 6 so that the cloth 8 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com