Optical glass with high refraction index and manufacturing method thereof

A technology of optical glass and refractive index, applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems of low transition temperature, mold surface erosion and damage, unsatisfactory ratio, etc., and achieve small specific gravity and liquidus The effect of low temperature and low transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Preparation and performance measurement test of optical glass of the present invention

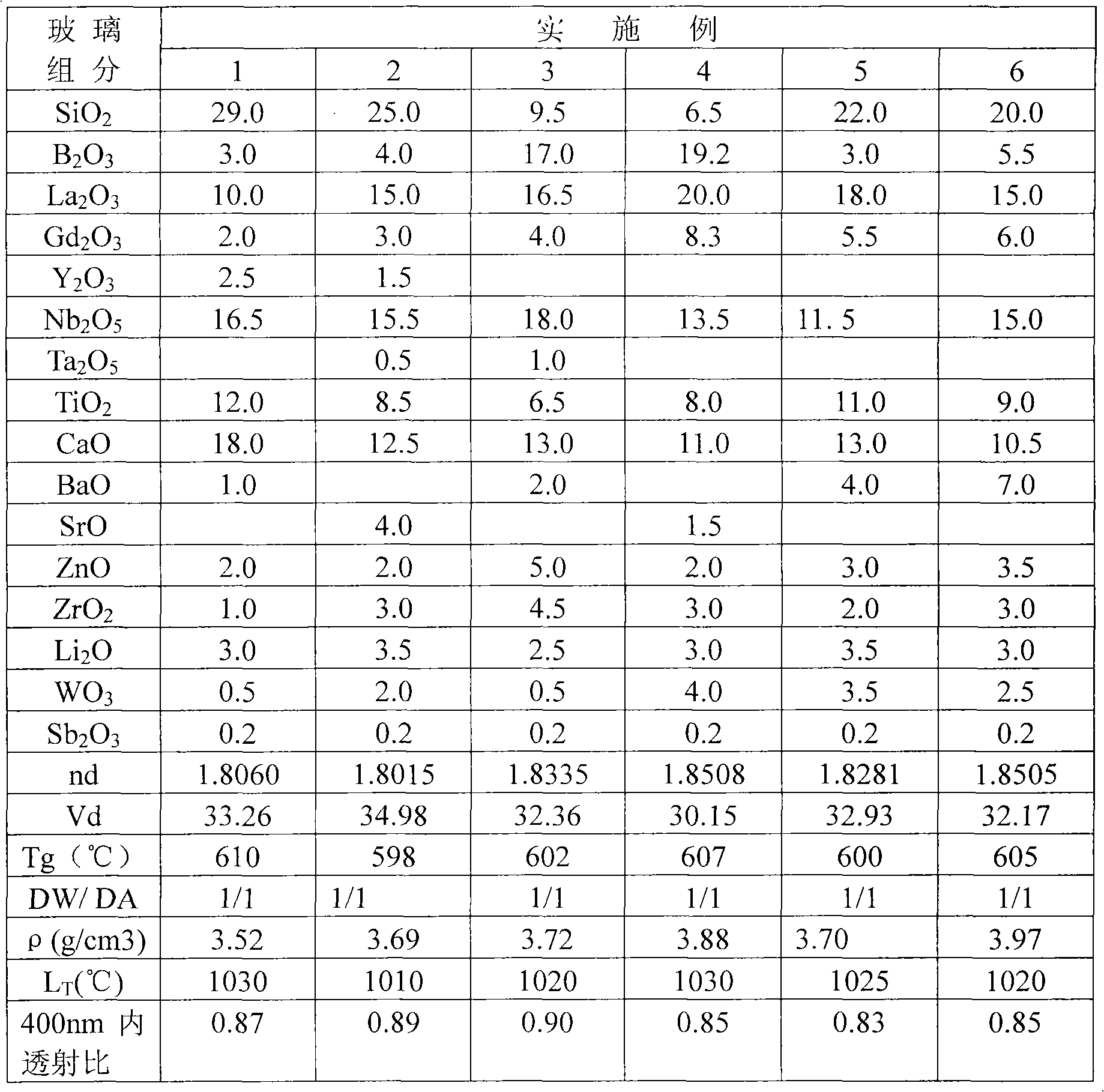

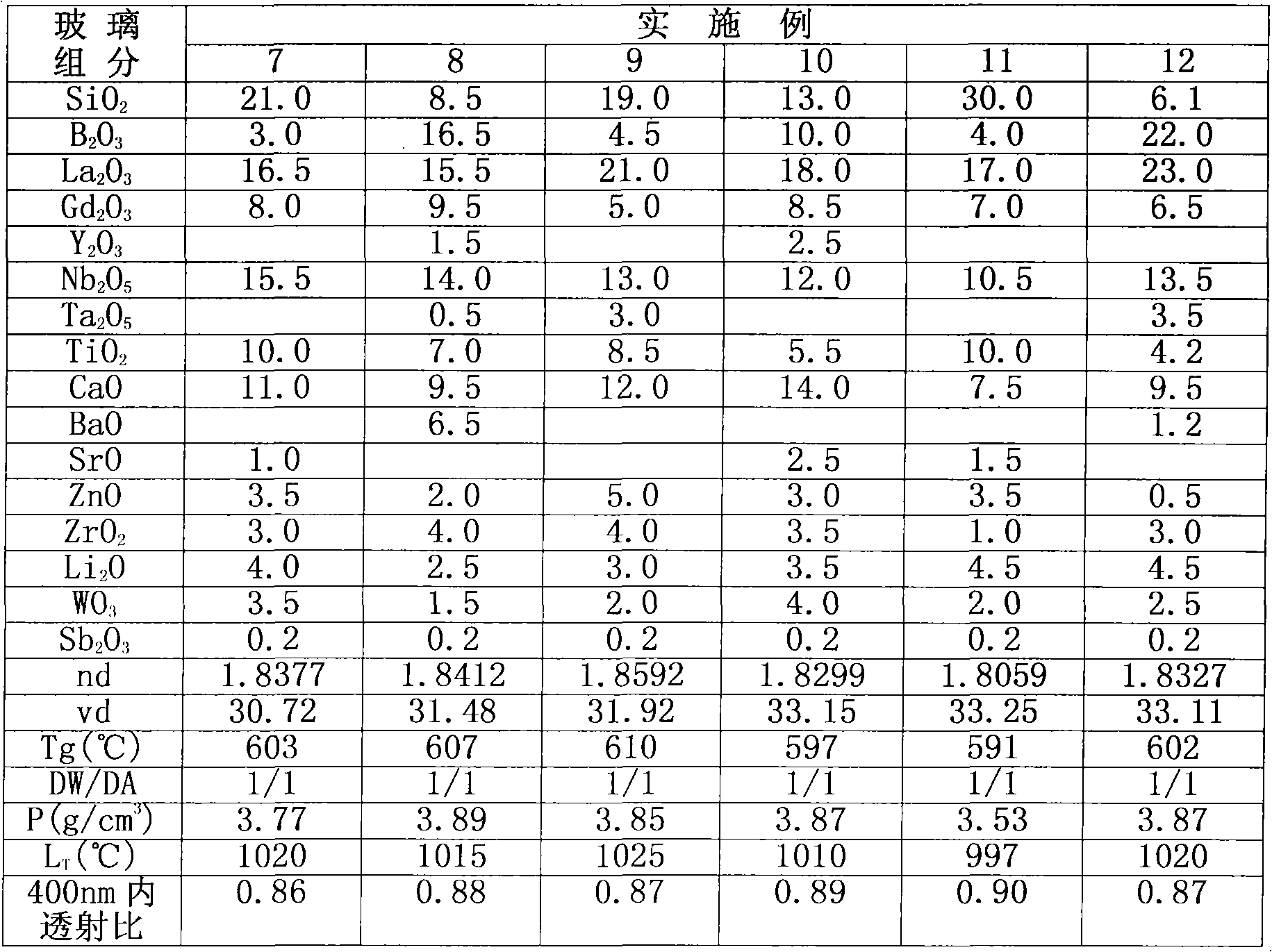

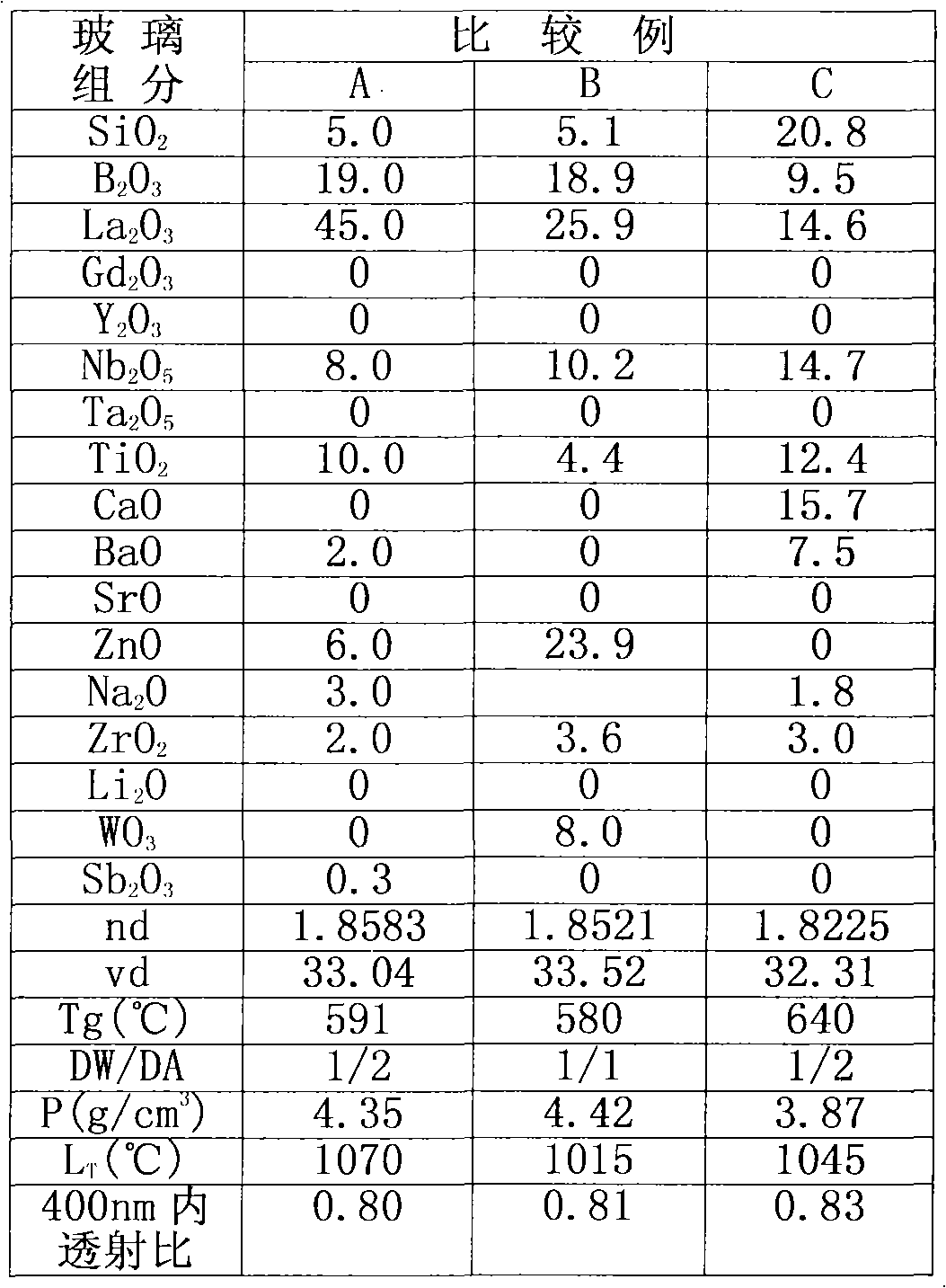

[0047] The specific preparation method of the optical glass of the present invention is as follows: first weigh various oxides, nitrates, carbonates and other raw materials according to Table 1 and Table 2, and then add clarifier Sb 2 o 3 , All kinds of raw materials are uniformly mixed by machine, and the batch materials are melted, stirred, clarified and homogenized at 1200°C-1350°C, and the optical glass of the present invention can be obtained through leakage or leakage molding to the blank and then cooling.

[0048] Sampling was carried out from the obtained glass to measure various properties. Tables 1 and 2 include components 1-12 and the measured optical and physical and chemical properties of the glass. Symbols indicate: DW, DA are chemical stability, LT is liquidus temperature, ρ is glass specific gravity, τ is internal transmittance at 400nm. Groups A, B, a...

Embodiment 2

[0077] Embodiment 2 Using the glass of the present invention to manufacture optical elements and its manufacturing method

[0078] An optical element was prepared from the optical glass described in Example 1.

[0079] The optical glass prepared in Example 1 is molded, heated to soften it, and shaped by a molding die to manufacture optical element blanks, which have good resistance to devitrification, mass-produce optical blanks, and then process optical blanks to produce various optical components. elements, manufactured as aspheric lenses. It can also be processed into optical components for secondary molding or precision molding, and after secondary molding, it is made into a spherical lens blank, and then processed to form a spherical lens.

[0080] The optical element formed by the invention is suitable for lenses used in digital cameras, digital video cameras and various photography.

[0081] In summary, the optical glass of the present invention has small specific gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com