Soft abrasive particle flow constraint runner device

A technology that constrains the flow channel and the flow of abrasive particles. It is applied in the direction of grinding/polishing equipment. It can solve the problems of long processing flow channel, small number of abrasive particles, and clogging of abrasive particles, so as to achieve engineering, improve processing efficiency, The effect of preventing clogging of the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

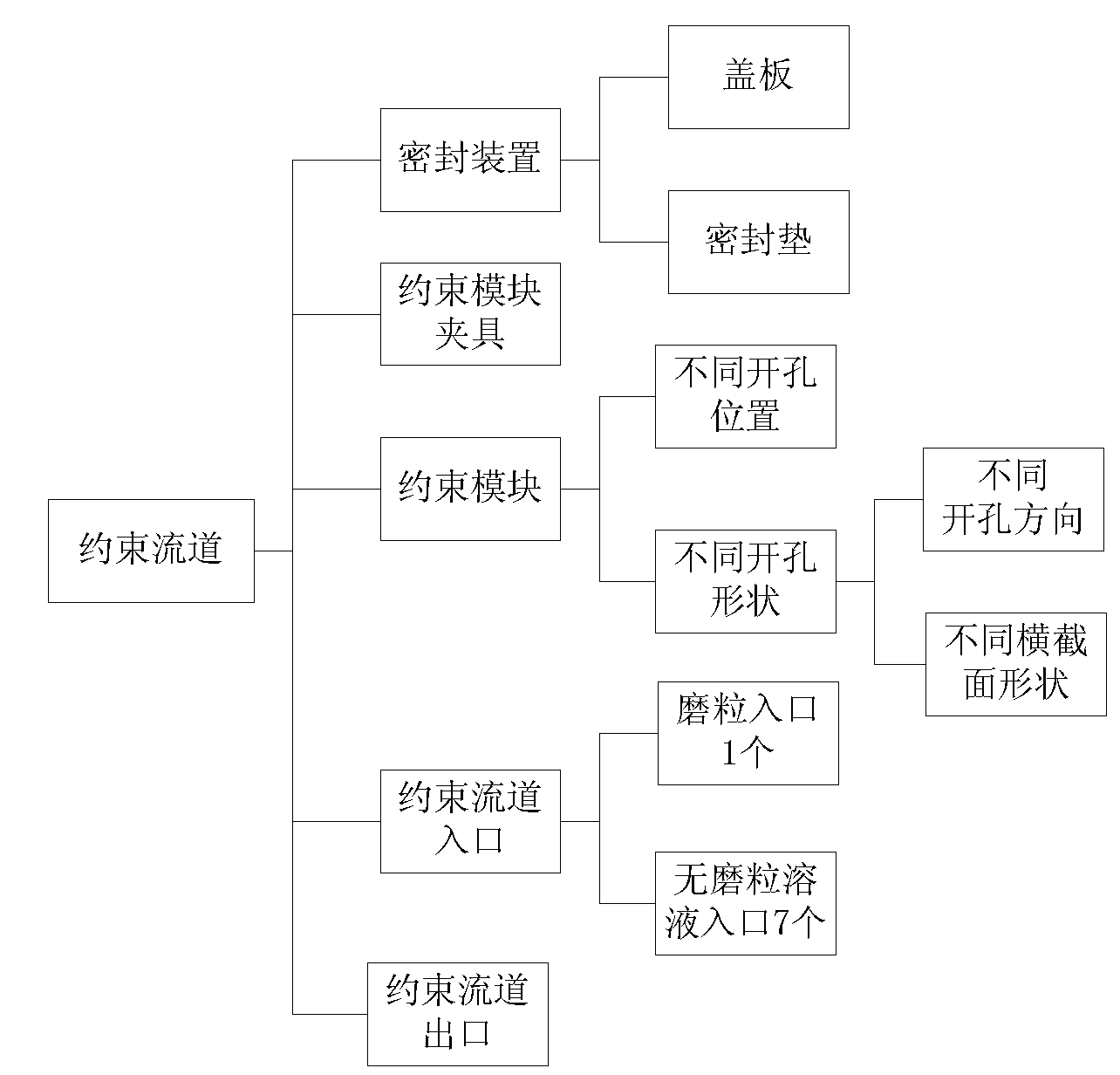

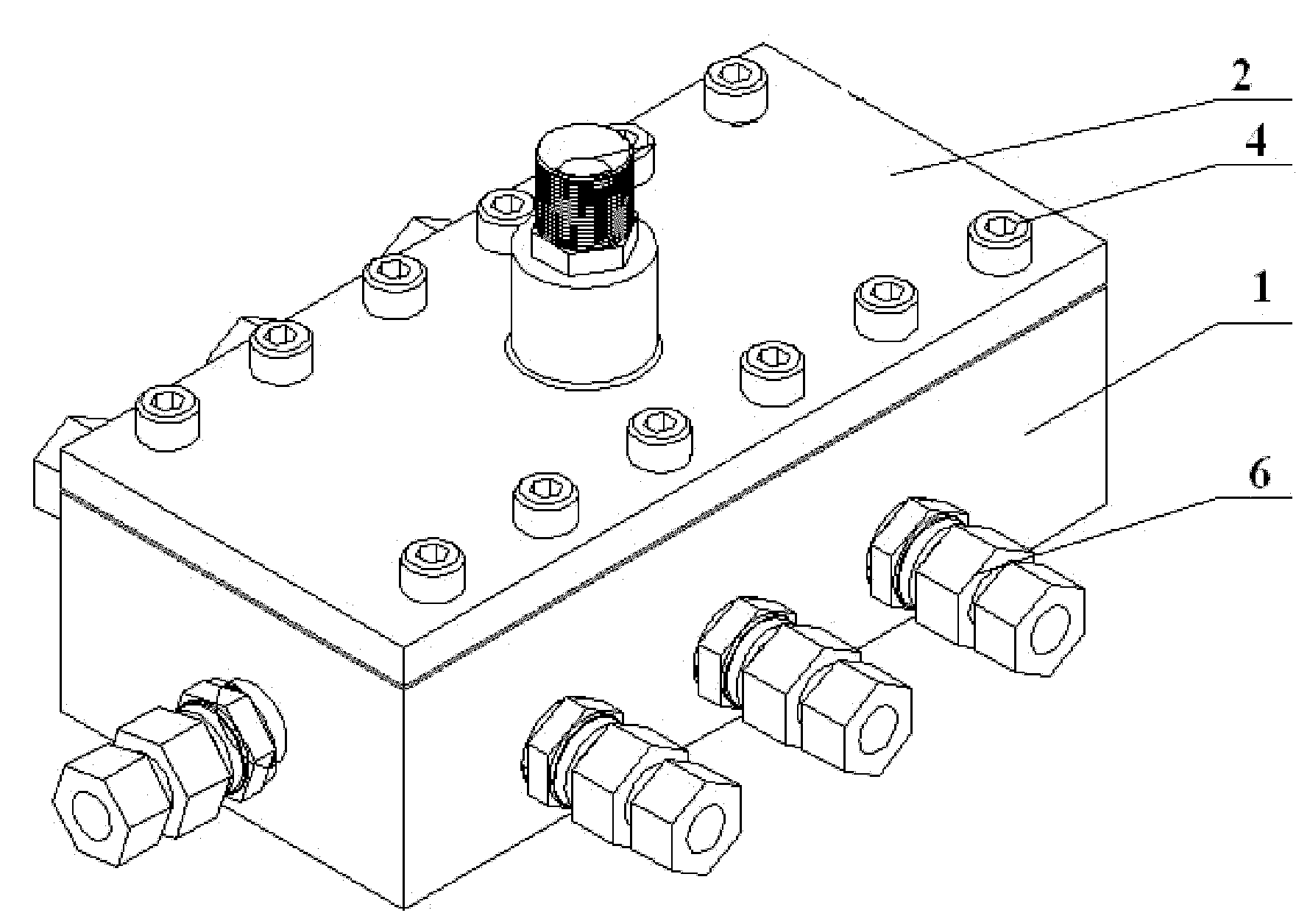

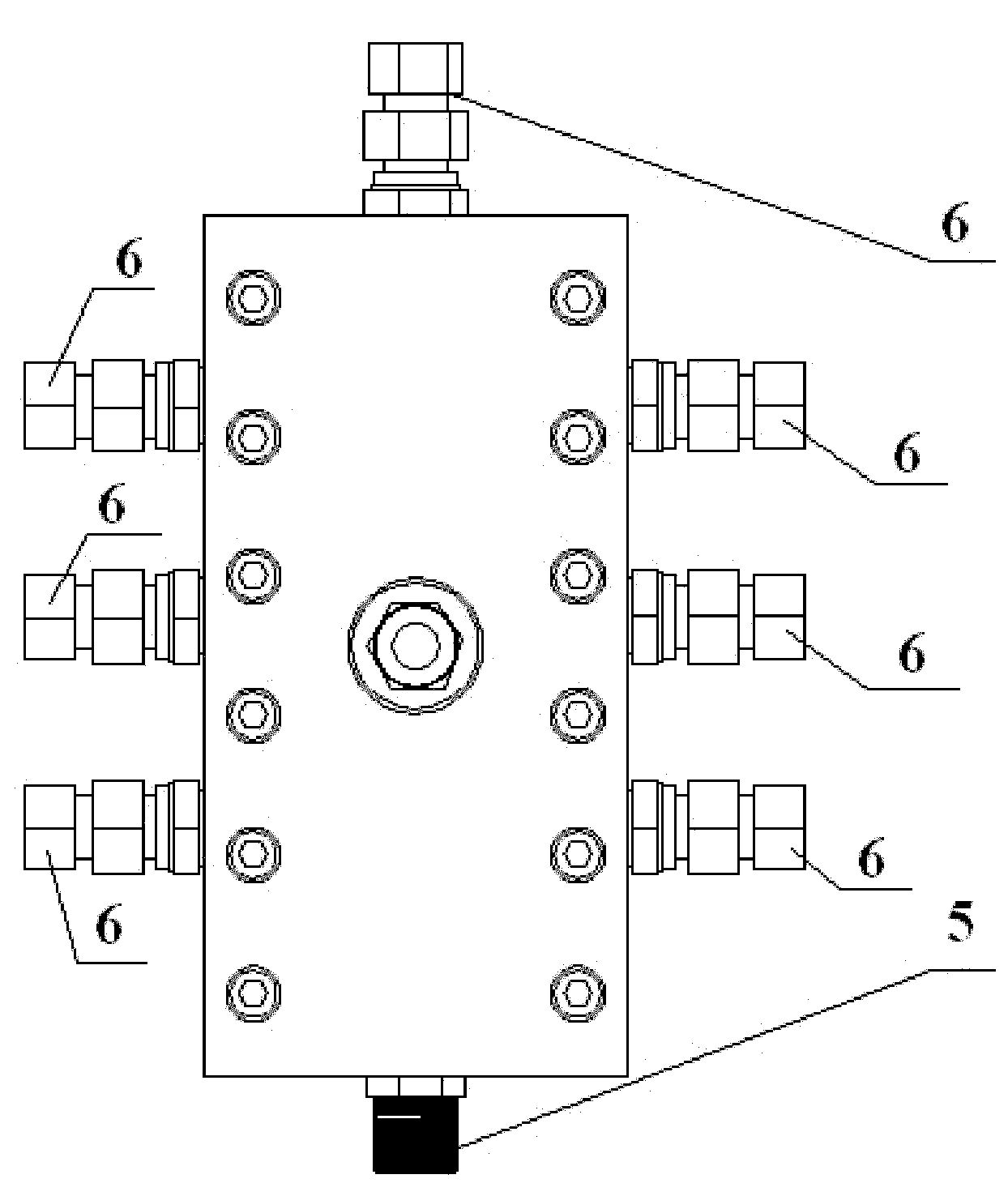

[0037] refer to Figure 1-8 , Figure 11 , 12

[0038] The soft abrasive particle flow restricting flow channel device includes a base 1 with a processing flow channel 11 inside and a cover plate 2 covering the base 1. The bottom plate of the base 1 is provided with a workpiece sink for accommodating workpieces to be processed 12. The top of the processing channel 11 is provided with a sealing sinker 13, and the sealing sinker 13 is provided with a sealing gasket 14 matching it;

[0039] The processing channel 11 is provided with a constraint module 3 and a fixture 4 for fixing the constraint module 3, the abrasive fluid impacts the workpiece to be processed through the constraint module 3, and the constraint module 3 is provided with an inclined passage for allowing the abrasive fluid to pass through. hole 31;

[0040] The cover plate 2 is connected to the base 1 through bolts 4, and the bottom of the cover plate 2 is provided with a boss 21 that is adapted to the gasket ...

Embodiment 2

[0070] refer to Figure 9 , 10

[0071] The difference between this embodiment and the first embodiment lies in that a pair of inclined through holes 31 are symmetrically opened on the constraining module 3 , and the cross section of the through holes 31 is triangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com