Ceramide dispersion and method for producing same

一种神经酰胺、制造方法的技术,应用在化学仪器和方法、非有效成分的医用配制品、含有效成分的医用配制品等方向,能够解决难以确保经时稳定性、损害安全性、可用性、稳定分散经时稳定性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

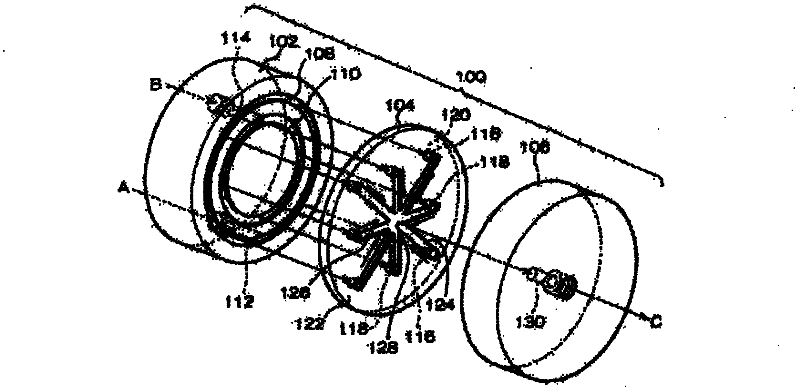

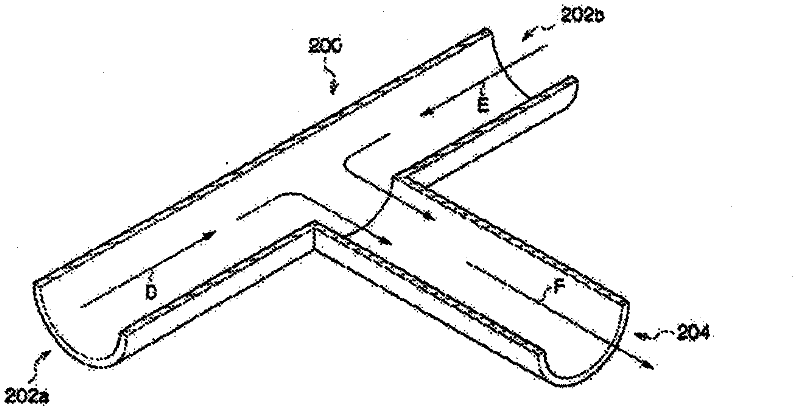

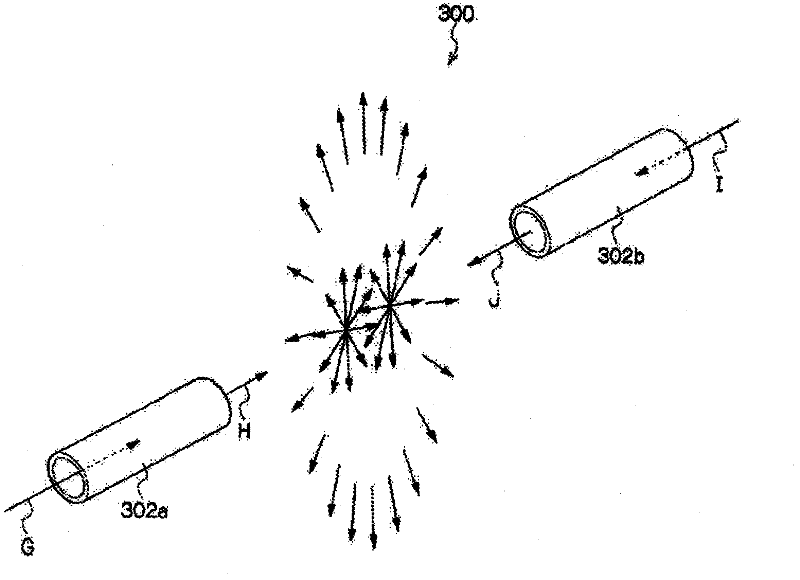

[0220] When micro-mixture is used in the preparation of emulsion with small particle size as one of the microchemical processes, due to the low energy and low heat generation, compared with the usual stirring emulsification dispersion method and high-pressure homogenizer emulsification dispersion, it is easy to obtain uniform particle size, A good emulsion or dispersion with excellent storage stability. It is the best method for emulsification containing natural ingredients that are easily deteriorated by heat.

[0221] The outline of the method of emulsifying or dispersing using a micro mixer is to divide the water phase and the oil phase into minute spaces, and to make the respective minute spaces contact or collide with each other. This is different from the method of dividing only one part into a small space and the other in bulk, and is obviously different from the membrane emulsification method and the microchannel emulsification method. In fact, only one part is divided...

Embodiment 1

[0276] The components described in the following oil phase liquid 1 composition were stirred at room temperature for 1 hour to prepare oil phase liquid 1.

[0277]

specific example 1-10

[0278] Ceramide 3B [natural ceramide, specific examples 1-10] 0.9 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com