Method for inducing and separating out orientation controllable lithium niobate single crystal in glass by using femtosecond laser

A technology of femtosecond laser and lithium niobate, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

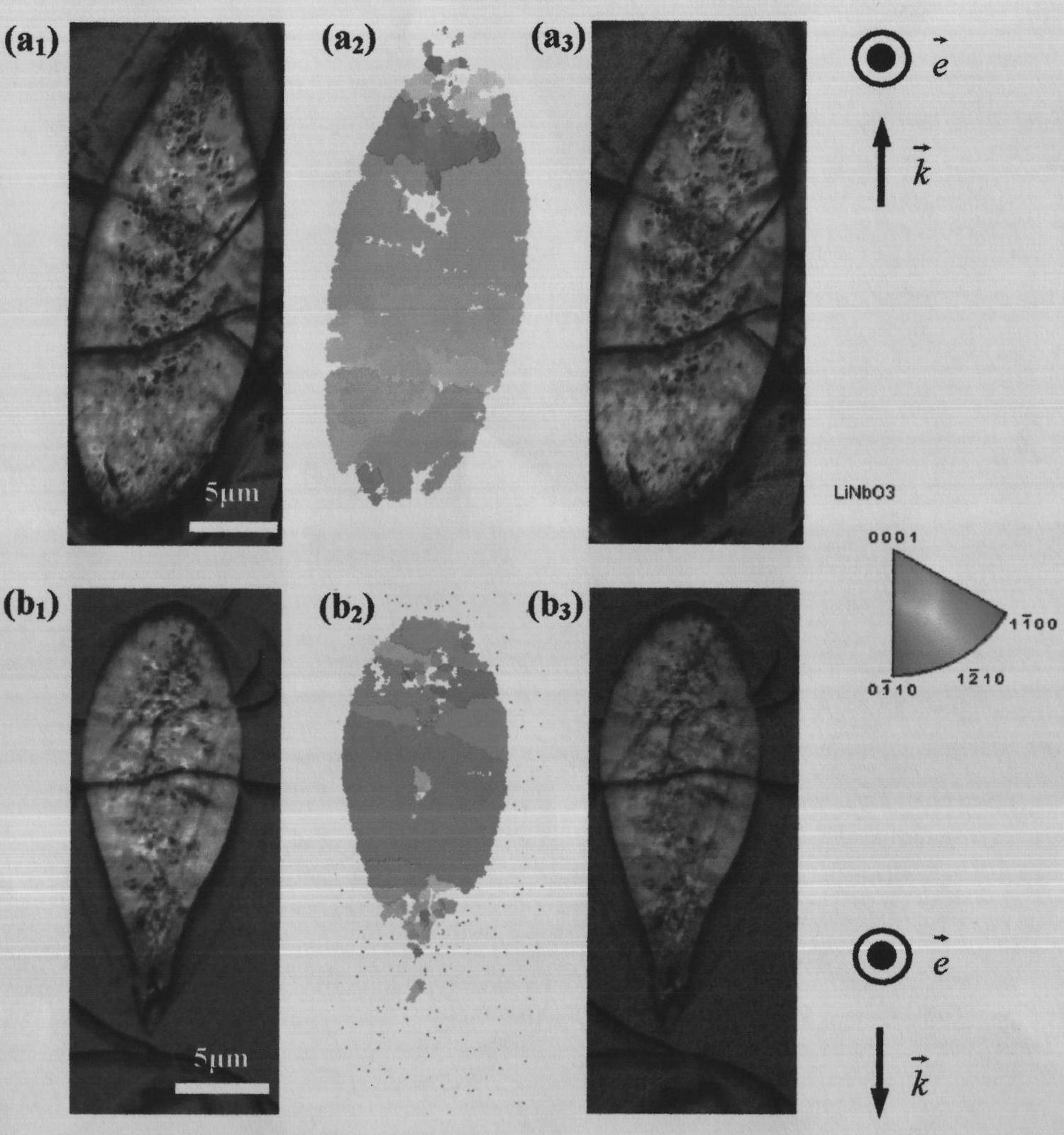

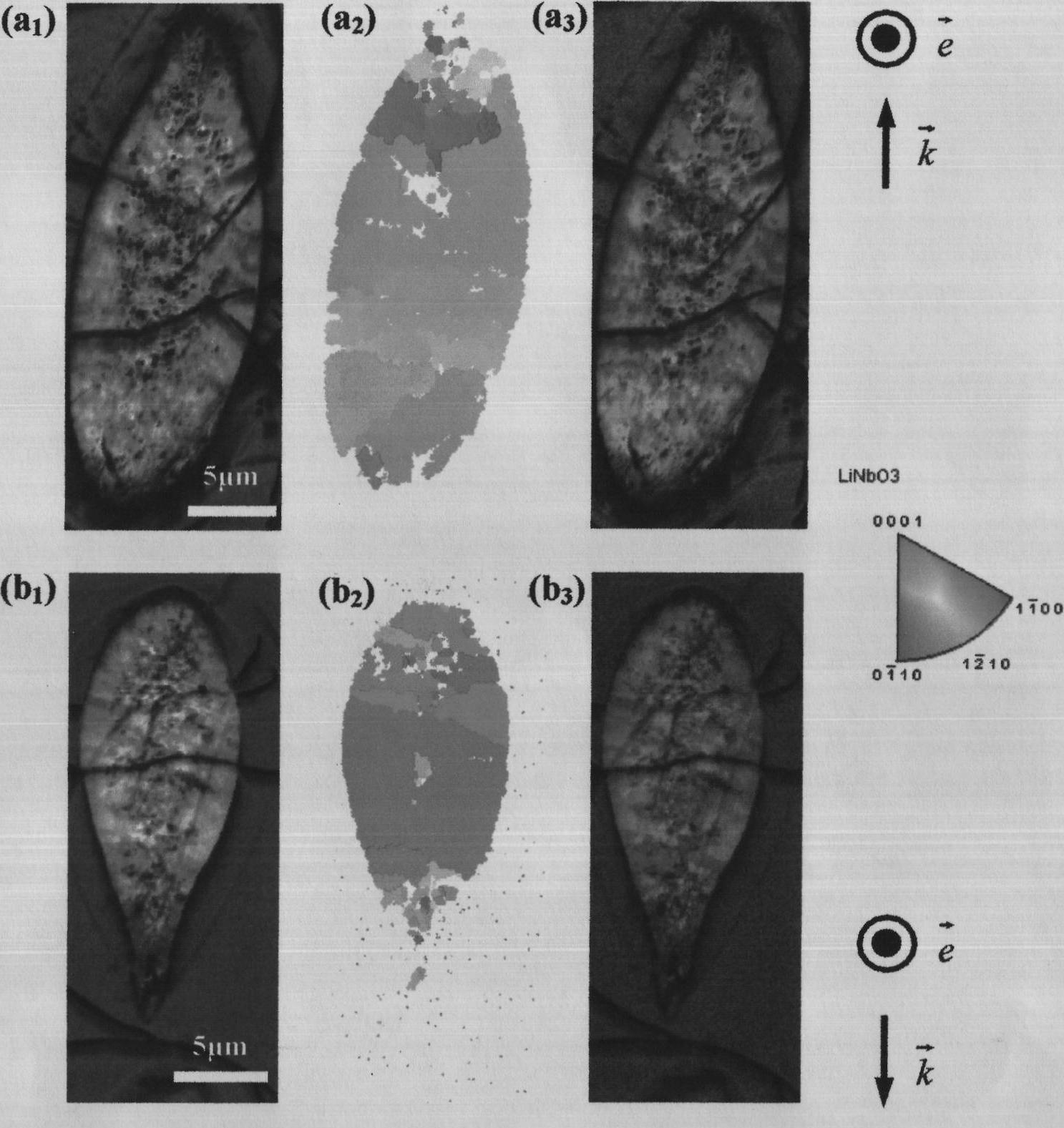

Image

Examples

Embodiment 1

[0013] First prepare the mole percentage as SiO 2 : Li 2 O: Nb 2 o 5 = 34%: 33%; 33%. Glass 34SiO 2 ·33Li 2 O·33Nb 2 o 5 (mol%). Using quartz sand, lithium carbonate, and niobium oxide as the main raw materials, first weigh 7.14 grams of quartz sand, 13.44 grams of lithium carbonate, and 30.73 grams of niobium oxide, grind and mix the above materials, put them into a quartz crucible or a platinum crucible, and place Put it into a high-temperature furnace; melt at 1400°C for 2 hours to melt the raw materials into a liquid state and mix the molten materials evenly. After heating the molten material at a constant temperature for 2 hours, take out the crucible from the high-temperature furnace, quickly pour the molten material in the crucible onto the preheated mold to form a glass sample, put the glass sample into a furnace at 550°C, and slowly cool down and anneal for 12 hours , the annealed glass is cut and polished to obtain a light yellow transparent glass carrier. F...

Embodiment 2

[0017] First prepare the mole percentage as SiO 2 : Li 2 O: Nb 2 o 5 = 34%: 33%; 33%. Glass 34SiO 2 ·33Li 2 O·33Nb 2 o 5 (mol%). Using quartz sand, lithium carbonate, and niobium oxide as the main raw materials, first weigh 7.14 grams of quartz sand, 13.44 grams of lithium carbonate, and 30.73 grams of niobium oxide, grind and mix the above materials, put them into a quartz crucible or a platinum crucible, and place Put it into a high-temperature furnace; melt at 1400°C for 2 hours to melt the raw materials into a liquid state and mix the molten materials evenly. After heating the molten material at a constant temperature for 2 hours, take out the crucible from the high-temperature furnace, quickly pour the molten material in the crucible onto the preheated mold to form a glass sample, put the glass sample into a furnace at 550°C, and slowly cool down and anneal for 12 hours , the annealed glass is cut and polished to obtain a light yellow transparent glass carrier. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com