Coal tar alkali-free short-flow normal/reduced-pressure distillation process and device

A coal tar, short-process technology, applied in tar processing, tar processing through distillation, tar removal processing through water, etc., can solve problems such as sales difficulties, corrosion, product quality and use impact, and achieve easy sales, The effect of low operating temperature and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

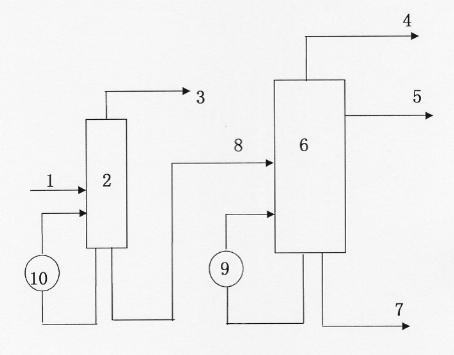

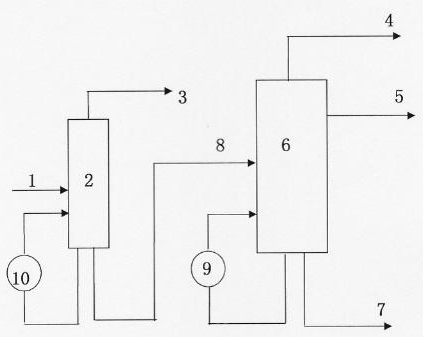

[0032] see figure 1 , a kind of coal tar of the present invention does not add alkali short process normal pressure vacuum distillation process, comprises dehydration tower 2 and main tower 6, comprises the following steps:

[0033] (1) The raw material tar 1 enters the dehydration tower 2 after heat exchange, and the light oil 3 distillate and water are extracted from the top of the dehydration tower 2.

[0034] (2) The tar at the bottom of the dehydration tower 2 enters the main tower 6 after heat exchange, and 4 fractions of phenol oil are extracted from the top of the main tower 6; 5 fractions of mixed oil are extracted from the side line; 7 fractions of soft asphalt or carbon black oil are extracted from the bottom of the tower; The material at the bottom of the main tower 6 is extracted, and after being heated to increase the temperature, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com