Plug used for shaping of branch pipe of super pipeline and process for shaping branch pipe of pipeline by using the same

A technology of super pipe and forming process, applied in the field of super pipe processing technology, can solve problems such as low yield, fracture, crack, etc., and achieve the effect of promoting bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

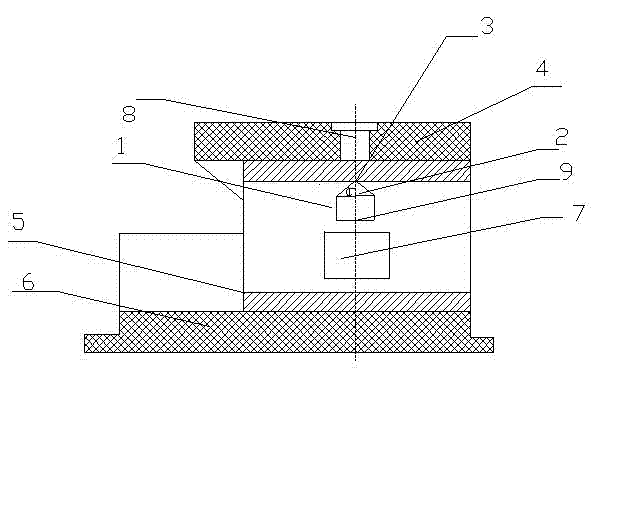

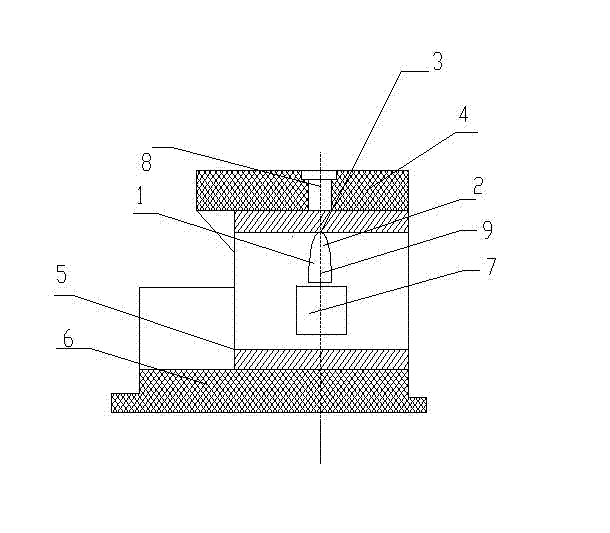

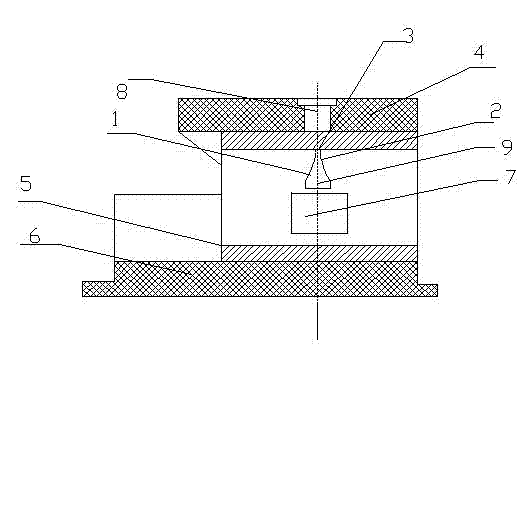

[0054] In this embodiment, the working end of the plug 1 used for super pipe branch forming is a section of the rotating body 2, and the generatrix of the rotating body 2 is a straight line, that is, the rotating body 2 is a cone 2, and the rotating body 2 The cross-sectional area of a section of the body 2 decreases gradually along the advancing direction of the plug 1, and the angle α between the generatrix of the cone 2 and the centerline of the cone 2 is 15° (see Figure 6 ); the cone 2 has a top fillet 3, in this embodiment, the radius of the top fillet 3 is 0.2 times the radius of the bottom surface of the cone 2 (see Figure 8 ); the bottom surface of the cone 2 in this embodiment is coaxially combined with a cylinder 9 and has a smooth transition, and the radius of the cylinder 9 is equal to the radius of the bottom surface of the cone 2 (see Figure 4-Figure 7 ).

[0055] In addition, in other embodiments of the present invention, when the working end of the plug (...

Embodiment 2

[0063] In this embodiment, the working end of the plug 1 used for super pipe branch forming is a section of the rotating body 2, and the generatrix of the rotating body 2 is a straight line, that is, the rotating body 2 is a cone 2, and the rotating body 2 The cross-sectional area of a section of the body 2 decreases gradually along the advancing direction of the plug 1, and the angle α between the generatrix of the cone 2 and the centerline of the cone 2 is 70° (see Figure 7 ), the cone 2 has a top fillet 3, in this embodiment, the radius of the top fillet 3 is 0.2 times the radius of the bottom surface of the cone 2 (see Figure 8 ); the bottom surface of the cone 2 in this embodiment is coaxially combined with a cylinder 9 and has a smooth transition, and the radius of the cylinder 9 is equal to the radius of the bottom surface of the cone 2 (see Figure 4-Figure 7 ).

[0064] In this embodiment, the technological process for forming super pipe branch pipes using the pl...

Embodiment 3

[0071] In this embodiment, the working end of the plug 1 used for super pipe branch forming is a section of the rotating body 2, and the generatrix of the rotating body 2 is a straight line, that is, the rotating body 2 is a cone 2, and the rotating body 2 The cross-sectional area of the body 2 decreases gradually along the advancing direction of the plug 1, and the angle α between the generatrix of the cone 2 and the centerline of the cone 2 is α30° (see Figure 4 ); the cone 2 has a top fillet 3. In this embodiment, the chord length corresponding to the arc of the top fillet 3 is 0.2 times the radius of the bottom surface of the cone 2 (see Figure 8 ); the bottom surface of the cone 2 in this embodiment is coaxially combined with a cylinder 9 and has a smooth transition, and the radius of the cylinder 9 is equal to the radius of the bottom surface of the cone 2 (see Figure 4-Figure 7 ).

[0072] In this embodiment, the technological process for forming super pipe branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com