Vertical automatic coating production line of aluminum profile

An automatic coating, material vertical technology, applied to the surface coating device, coating, liquid spraying equipment and other directions, can solve the problems of high cost and rare users, achieve low leakage, prevent tilt, prevent drying The effect of furnace deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

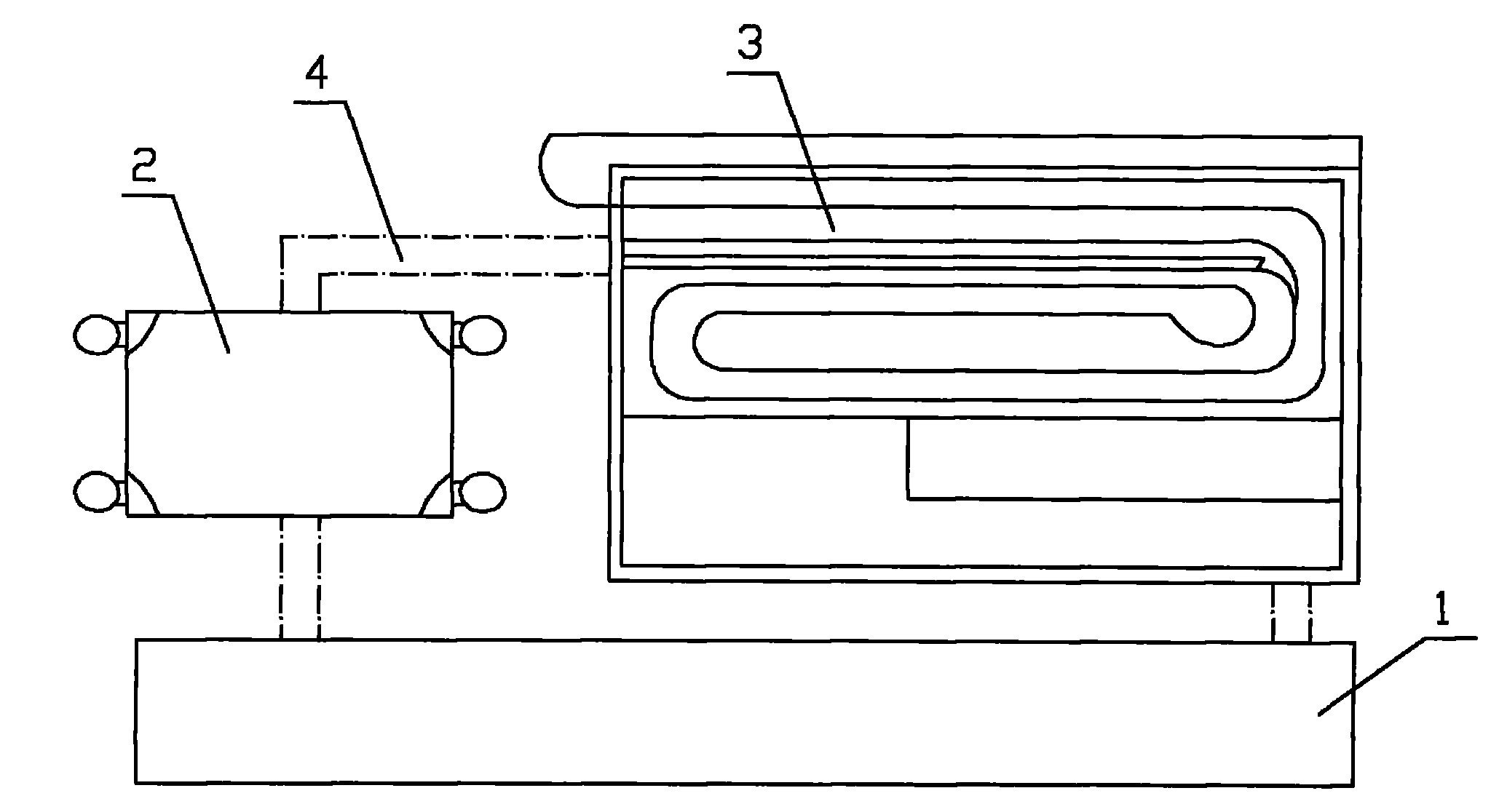

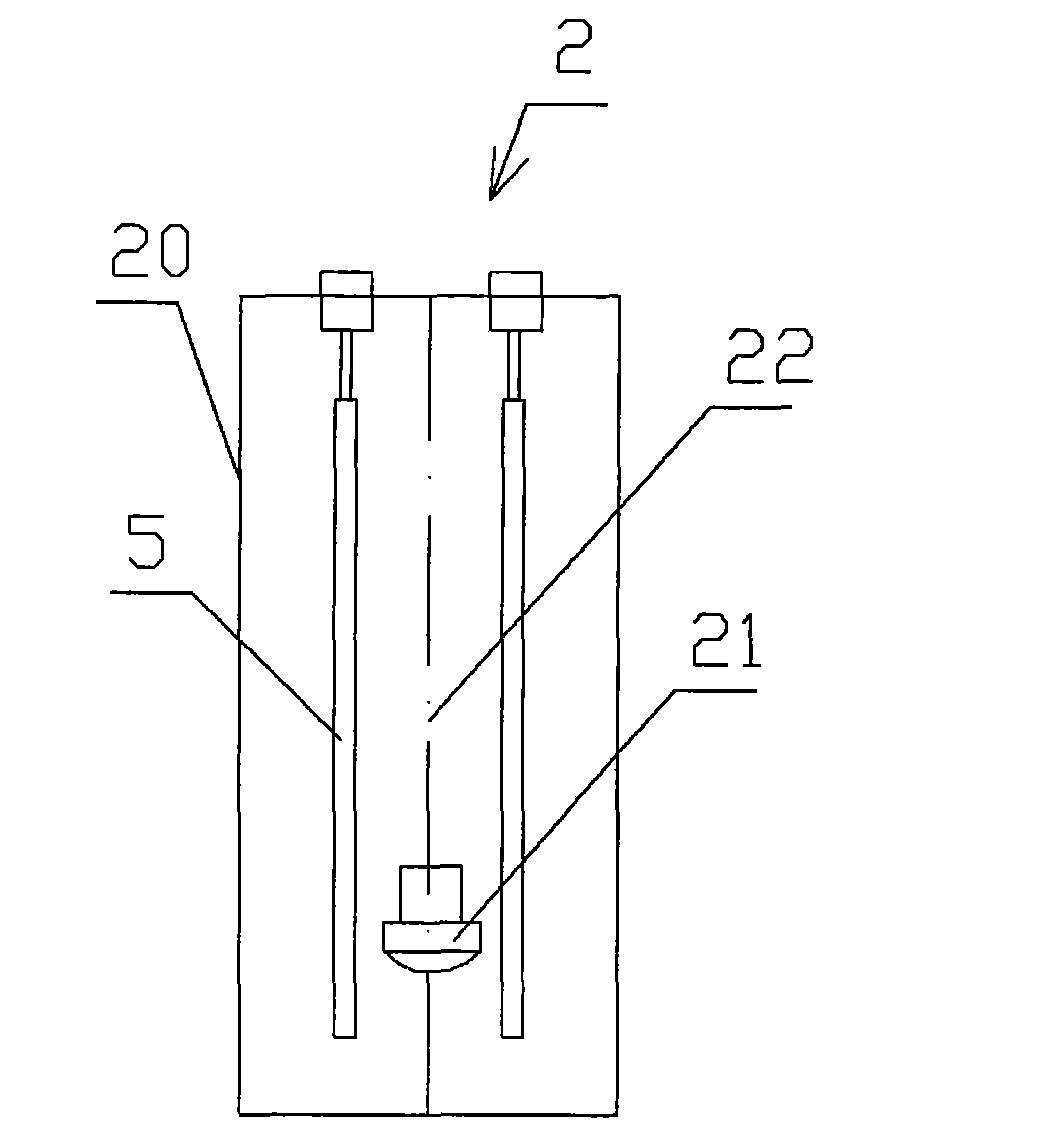

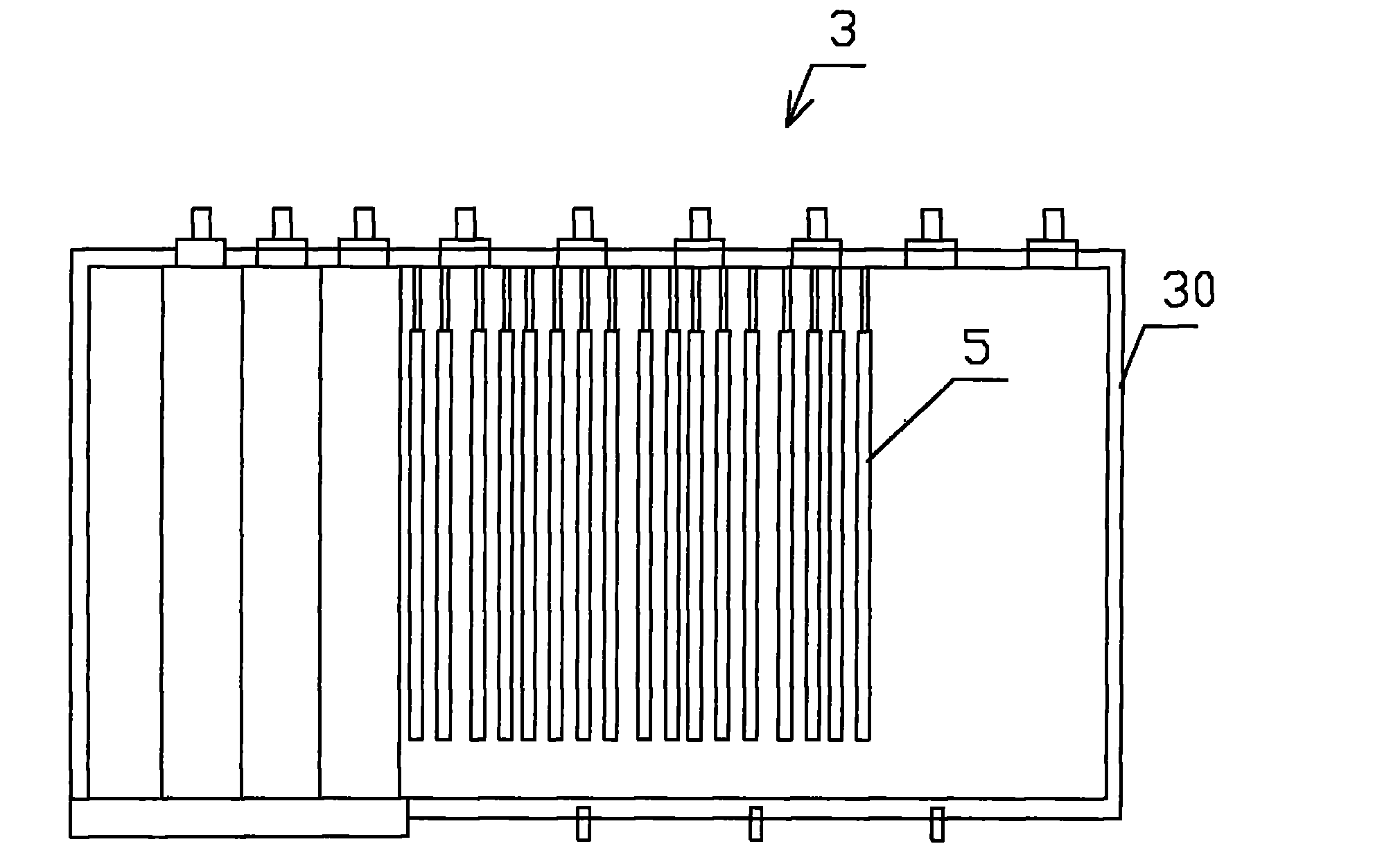

[0014] Example: see Figure 1~4 As shown, the aluminum profile vertical automatic coating production line includes pre-processing equipment 1, spraying equipment 2 and drying equipment 3. The pre-processing equipment 1 and drying equipment 3 are connected by a conveyor belt 4, and the drying tunnel of the drying equipment 3 The shell 30 is composed of a rubber seal layer 31, an inner rock wool layer 32, an air insulation layer 33 and an outer rock wool insulation layer 34 from the inside to the outside. The workpiece 5 is vertically hung on the spraying equipment 2 and the drying equipment 3. middle.

[0015] The height of the glue-sealed board layer 31 is greater than 8.6 meters.

[0016] The spray plate 21 of the spraying equipment 2 slides along the guide rail 22, and the guide rail 22 is fixed in the spraying chamber 20 of the spraying equipment and placed in the circle center of the circle passing through the main axes of the two workpieces 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com