Method for preparing fluorocarbon polymer microporous film with interpenetrating network bicontinuous pore structure

A fluorocarbon polymer and interpenetrating network technology, applied in the field of membrane separation, can solve the problems of high energy consumption and high requirements, and achieve high rejection rate and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

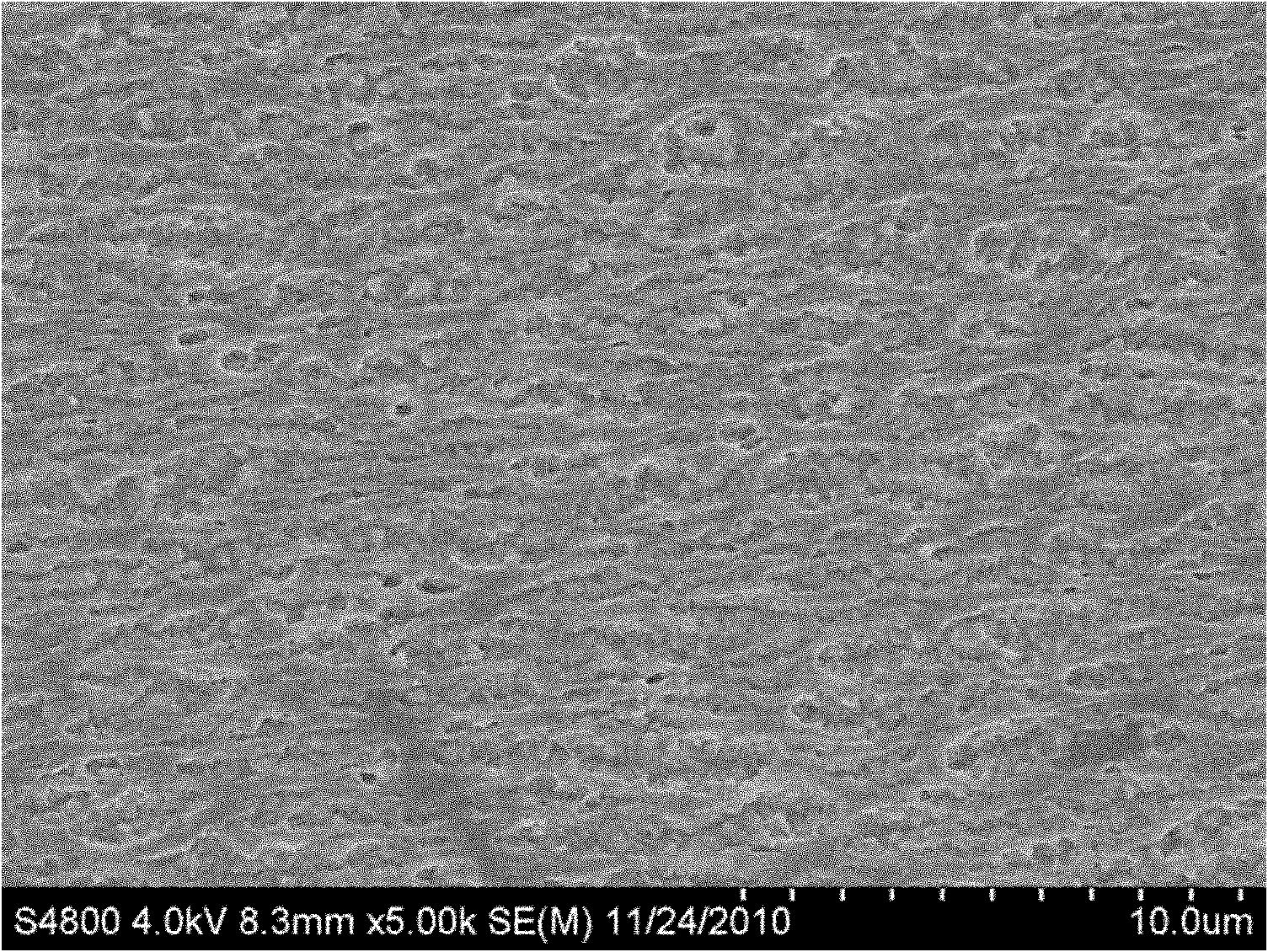

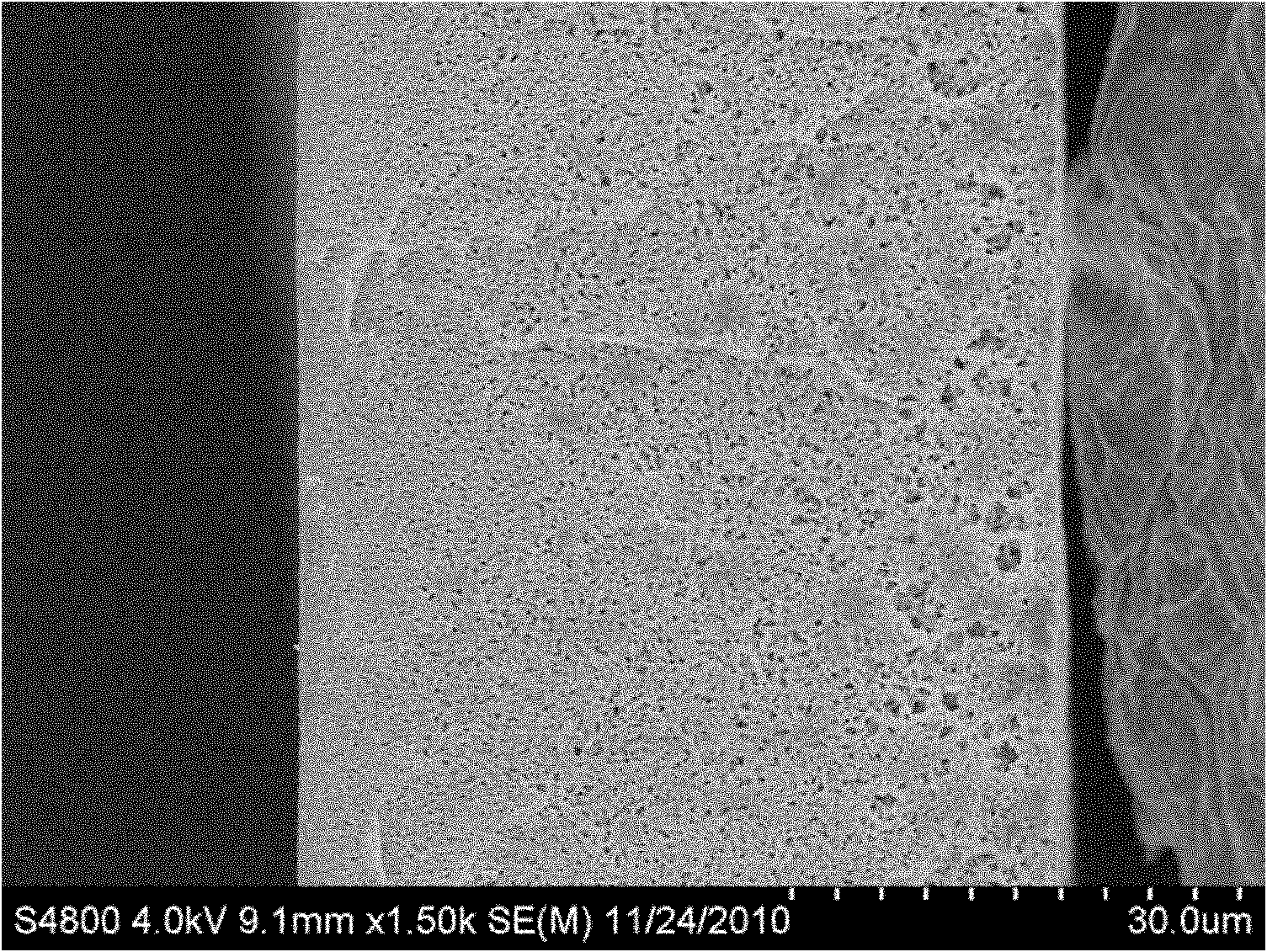

[0029] At a temperature of 80°C and an air humidity of 50%, the vinylidene fluoride-hexafluoropropylene copolymer with a mass percentage of 12% was stirred and dissolved in a mass percentage of 88% by mass at a stirring speed of 150 rpm. % of tetramethylurea, the stirring time is 24 hours, and then stand at 80 ° C for 24 hours to form a metastable equilibrium casting solution; the casting solution is processed and formed by a flat composite film forming machine The primary film of the flat composite film is controlled to evaporate in the air for 5 seconds; the primary film is immersed in the first coagulation bath composed of pure water at 28°C for 30 minutes, and then the film is transferred to the pure water at 28°C. In the second coagulation bath composed of water for 30 minutes; after removing the residual solvent, dry it to obtain a flat vinylidene fluoride-hexafluoropropylene copolymer flat composite ultrafiltration membrane with an interpenetrating network double continu...

Embodiment 2

[0033] At a temperature of 60°C and an air humidity of 60%, polyvinylidene fluoride was stirred and dissolved in a mixed solvent of hexamethylphosphoramide and triethyl phosphate at a stirring speed of 300 rpm. In terms of content, in the whole solution, the content of polyvinylidene fluoride is 15%, the content of hexamethylphosphoramide is 20%, the content of triethyl phosphate is 65%, the stirring time is 24 hours, and then at 60 ℃ Leave standstill for 12 hours for defoaming to form a metastable equilibrium casting solution; the casting solution is processed and formed into a flat film nascent film by a flat film film forming machine, and its evaporation time in air is controlled to be 10 seconds; The nascent film was immersed in the first coagulation bath composed of a mixed solution of triethyl phosphate and water at 30°C for 10 seconds, wherein the mass percentage of triethyl phosphate in the mixed solution was 70%, and then the film was transferred to Put in the second ...

Embodiment 3

[0037] At a temperature of 60°C and an air humidity of 60%, stir and dissolve polyvinylidene fluoride with a mass percentage of 15% in 85% of hexamethyl at a stirring speed of 300 rpm In phosphoramide, the stirring time is 36 hours, and then stand at 60°C for 12 hours to defoam to form a metastable equilibrium casting solution; the casting solution is processed by a flat film forming machine to form a flat film primary film, And control its evaporation time in the air to be 10 seconds; immerse the nascent film in the first coagulation bath composed of a mixed solution of hexamethylphosphoramide and water at 30°C for 10 seconds, wherein hexamethylphosphoramide is in the mixed solution The mass percent content is 70%, and then the film is transferred to the second coagulation bath composed of a mixed solution of ethanol and pure water at a temperature of 30 ° C for 12 hours, wherein the mass percent content of ethanol in the mixed solution is 30 %; After removing the residual so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com