Method for absorbing and utilizing phosgene tail gas

A tail gas absorption and phosgene technology, applied in separation methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of unrealized industrial utilization value, environmental pollution, large waste acid, etc., and achieve easy operation and low investment , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

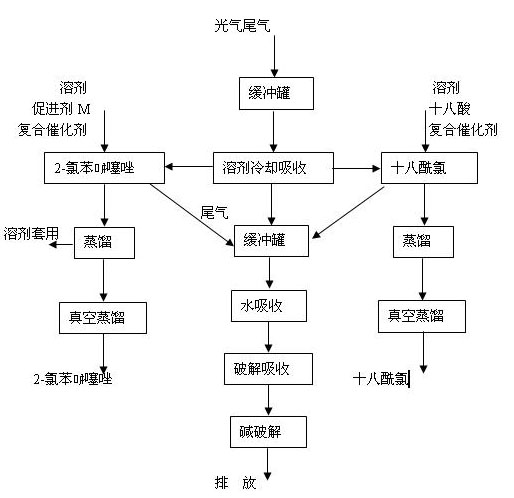

Method used

Image

Examples

Embodiment 1

[0027] Take a 500ml four-necked flask and add 250g of dichloroethane, stopper the bottle, weigh 548g, cool the material to -5°C to 0°C, and feed the phosgene tail gas in the production process of Diuron (the phosgene content is about 37% (V / V), hydrogen chloride 43%, carbon monoxide 20%), 400~500mg / min per minute, and the unabsorbed tail gas is absorbed and treated with 5% alkali. After 3 hours, the absorption was stopped, and 735g of the material bottle was weighed, and the weight of the solution increased by 187g, wherein the phosgene content was 29.5%, and the hydrogen chloride was 15.3%.

Embodiment 2

[0029] Take a 500ml four-neck flask and add 250g of chlorobenzene, stopper the bottle, weigh 539g, cool the material to -5°C to 0°C, and feed the phosgene tail gas in the production process of Lvmeron, (the phosgene content is about 38 % (V / V), hydrogen chloride 42%, carbon monoxide 20%), 400-500 mg / min is introduced per minute, and the unabsorbed tail gas is absorbed and treated with 5% alkali. Absorption was stopped after 3 hours, 728g of the material bottle was weighed, and the weight of the solution increased by 189g, wherein the content of phosgene was 30.2%, and the content of hydrogen chloride was 11.3%.

Embodiment 3

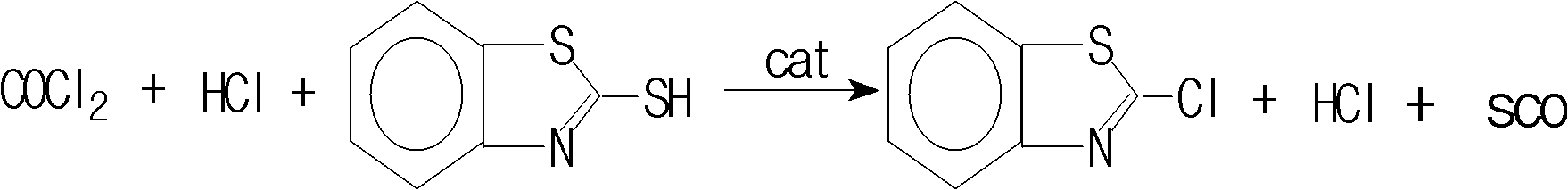

[0031] In the four-necked flask of 500ml, add dichloroethane 100ml, promotor M 50g, composite catalyst 2g (bipyridine 1.8g, Yb(OTf) 3 and 0.2g, sodium trifluoromethanesulfonate of ytterbium), be warming up to 70 ℃~75 ℃, add dropwise the phosgene dichloroethane solution 110g that absorbs in example 1, keep reaction temperature 70 ℃~75 ℃, tail gas water After absorption, use alkali to absorb, add dropwise for 5 hours, and keep warm for 1 hour to remove the dichloroethane solvent. The crude product is vacuum (0.7mmHg) distilled to obtain 2-chlorobenzene Thiazole 48.2g, content 99.1%, yield 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com