Method for preparing high-voltage cathode material lithium-nickel-manganese-oxygen battery

A positive electrode material, lithium-nickel-manganese-oxygen technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of not realizing comprehensive applications at the same time, and achieve the effect of promising market prospects, suitable for batch processing, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

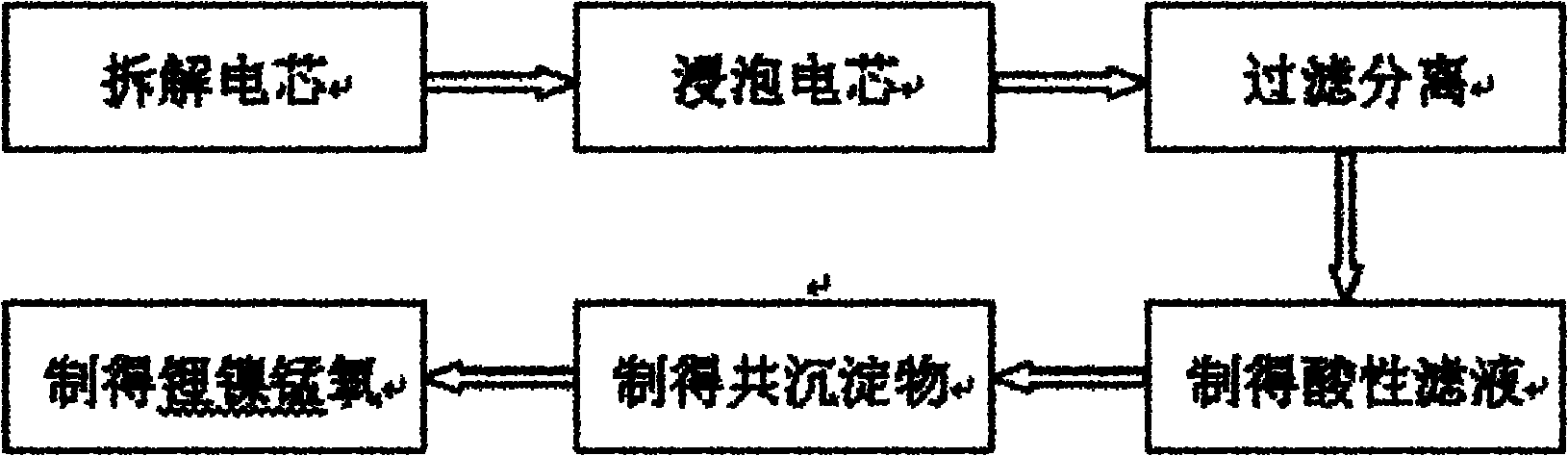

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Discharge 2 waste and old soft-packaged lithium manganese oxide power lithium ion batteries (one monomer is 5Ah) with special discharge equipment, remove the waste and old lithium manganate power battery of monomer soft-package by means of a shearing machine, take out the battery core, The outer packaging aluminum-plastic composite film is directly recycled. Crush the cell to 1cm with a vertical rotary grinder 2 About the size, soak the crushed cell fragments in N, N-dimethylformamide at a temperature of 60 degrees for 1 hour, accompanied by mechanical stirring and intermittent ultrasonic oscillation.

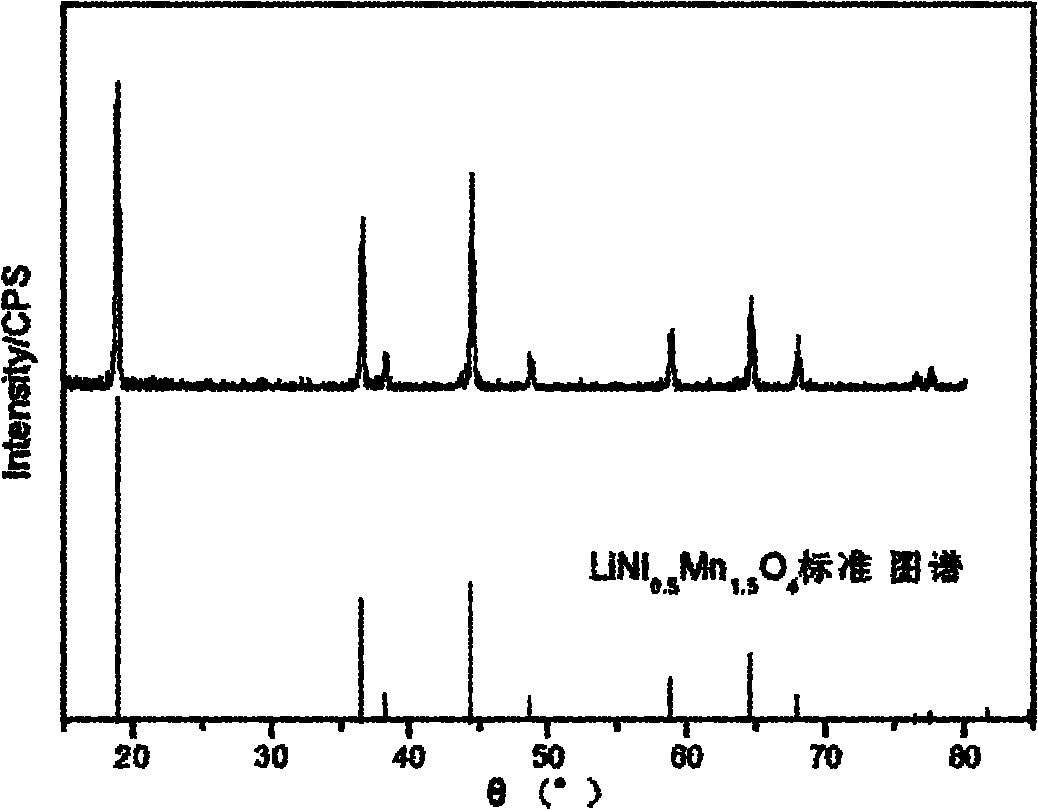

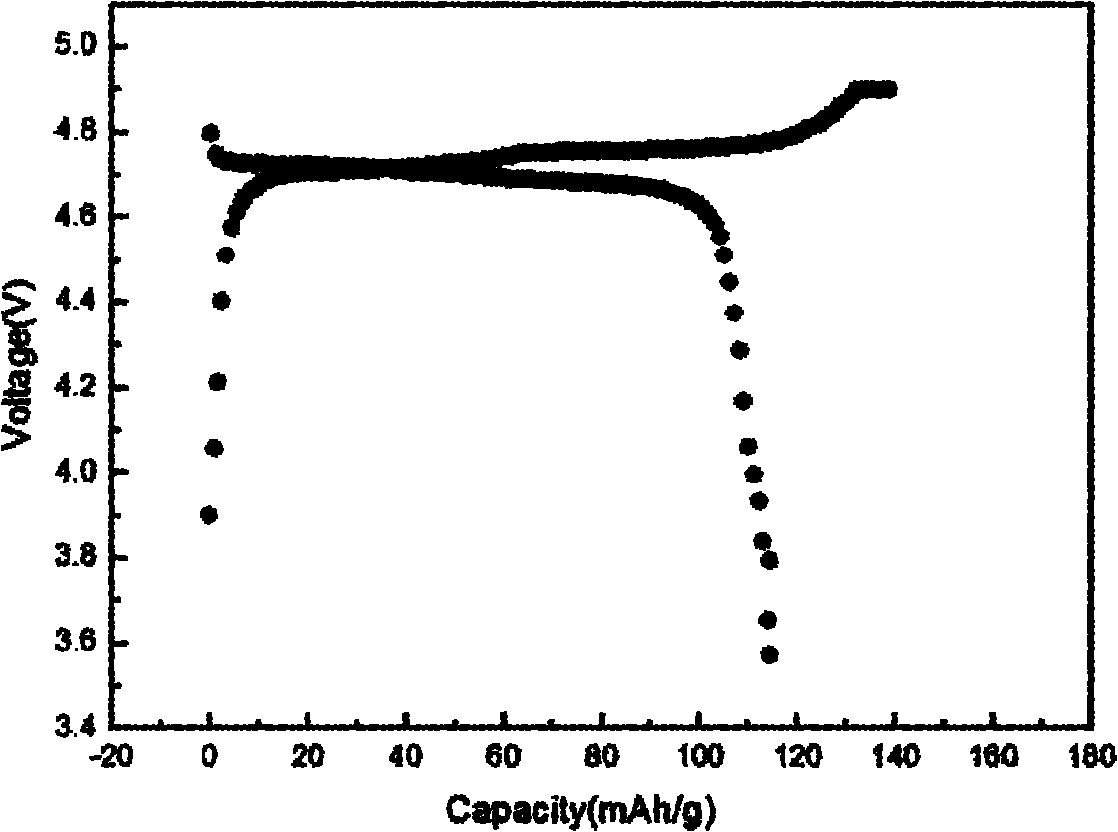

[0042] Then filter and separate the soaked cells from the solvent, wash and filter the filter residue with distilled water several times, dry at 120°C for 6 hours, vibrate and sieve, and get clean Al, Cu, Ni foils and diaphragms on the sieve, which can be directly sent to The smelting plant recycles the metal; the mixed powder of gray-black lithium mangana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com