Ultrahigh-current lead manufacturing method and lead and cable manufactured by using same

A technology of current wire and manufacturing method, which is applied in the direction of conductive layer on insulating carrier, insulated cable, cable/conductor manufacturing, etc., which can solve the problems of complex process, difficulty in large-scale promotion, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0019] Specific Implementation Mode Two Super-high Current Overhead Conductors

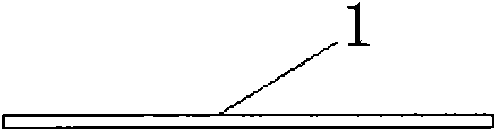

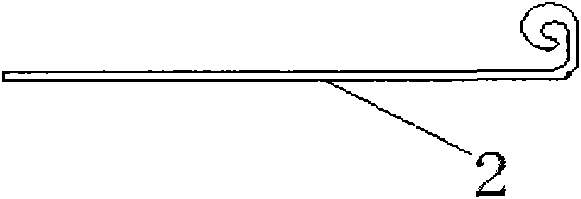

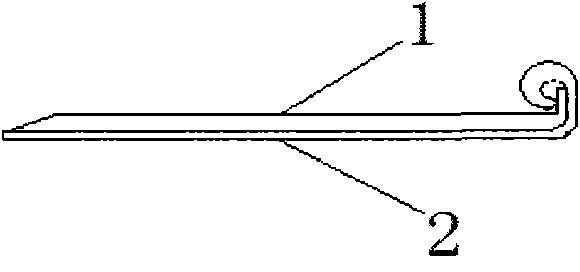

[0020] A kind of super-high-current wire manufacturing method that the present invention refers is that the conductor of traditional wire is pressed into conductor sheet such as figure 1 , the conductive sheet has two surfaces along which charges are transported. Then one side of this conductor sheet is attached with a layer of insulating material such as figure 2 . The conductor thin sheet of this adhesion insulating material layer is wound on the core wire 6 that bears tension again and is rolled into the cylinder of helix according to certain mode (as image 3 ) or square columns (such as Figure 4 ) or any other cylindrical shape. The technology of the present invention lies in turning all the metal materials of the wire core into conductor surfaces that can transmit electric energy together, so compared with the original production process, the utilization rate of the metal materials is ...

specific Embodiment approach 3

[0021] Specific embodiments of the invention Three cables made of ultra-high current conductors

[0022] A kind of super-high-current wire manufacturing method that the present invention refers is to take some common super-high-current wires referred to in the specific implementation mode (1) of the fundamental invention and combine them to coat the cable shielding protection layer 7 and the cable outer sheath 8 on the outside. into cables made of super-high current conductors. Such as: can take 2, 3 fundamentals or many ordinary super-high-current wires indicated in the specific embodiment of the invention (one) to make 2 phases, 3 phases or multiple cables with special effects. (Such as Figure 10 ) is a specific embodiment of the present invention (three) a three-phase cable made with a super-high current wire. (Because each item directly adopts the common ultra-high current wire indicated in the specific embodiment of the present invention (one) so its internal structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com