Expert system and method for preventing and controlling sludge bulking under the diagnosis based on operation condition of sewage disposal plant

A sewage treatment plant, sludge bulking technology, applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of misjudgment due to human reasons, slow diagnosis speed, etc., increase accident samples, realize prevention and The effect of the early warning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

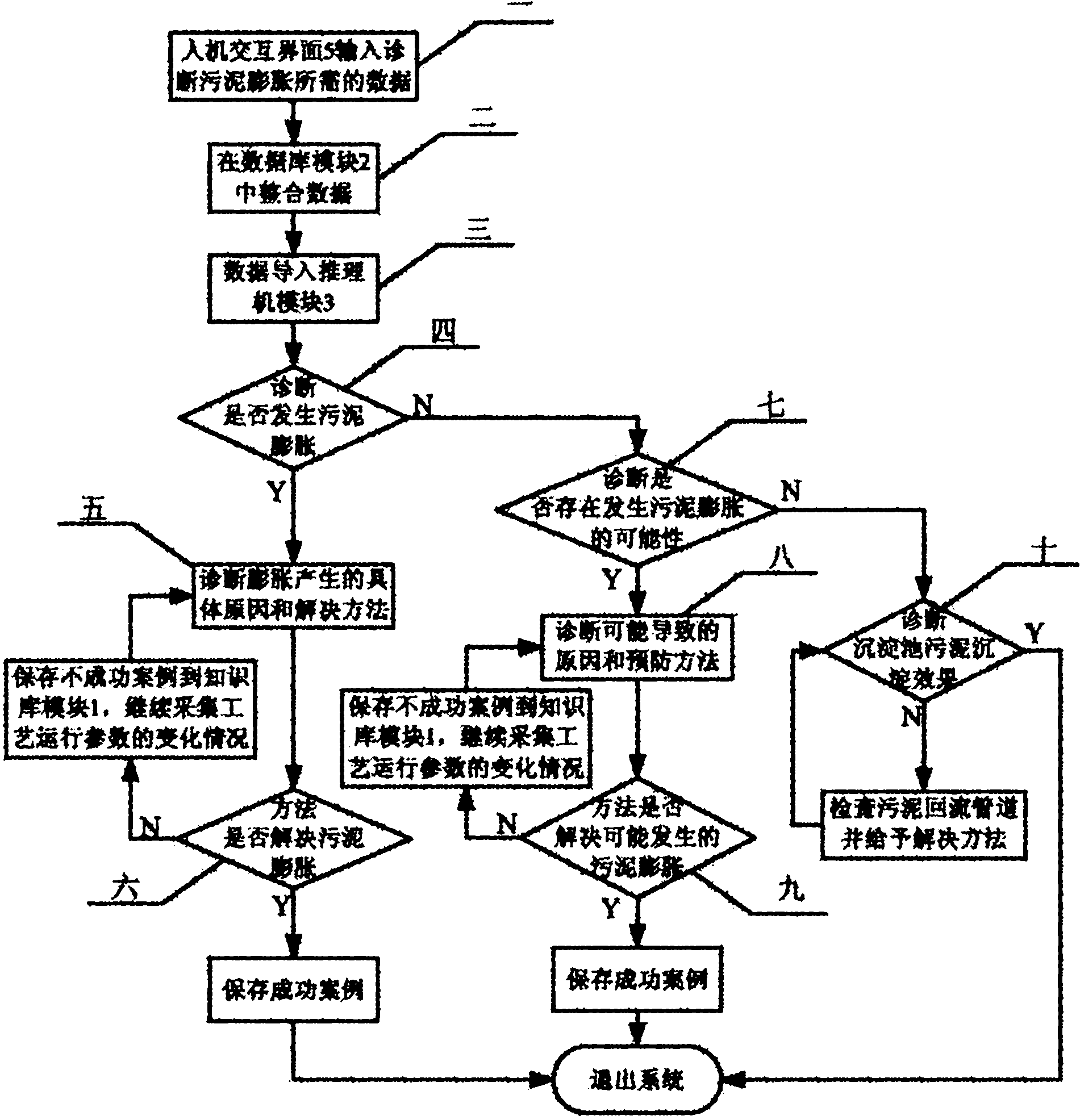

[0025] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, this embodiment includes knowledge base module 1, database module 2, reasoning machine module 3, explanation machine module 4 and human-computer interaction unit 5;

[0026] Knowledge base module 1 is used to store methods for diagnosing sludge bulking and controlling sludge bulking based on operating parameters of sewage treatment plants. The establishment of rules in knowledge base module 1 focuses on changes in process operating parameters and sludge settling performance. And the method in the knowledge base module 1 can be updated in time through the human-computer interaction unit 5, and successful cases and unsuccessful cases in the diagnosis and control process can be added;

[0027] The database module 2 is used to store the raw data obtained by the online monitoring instrument, the data detected offline and the secondary data generated during the diagnosis process;

[...

specific Embodiment approach 2

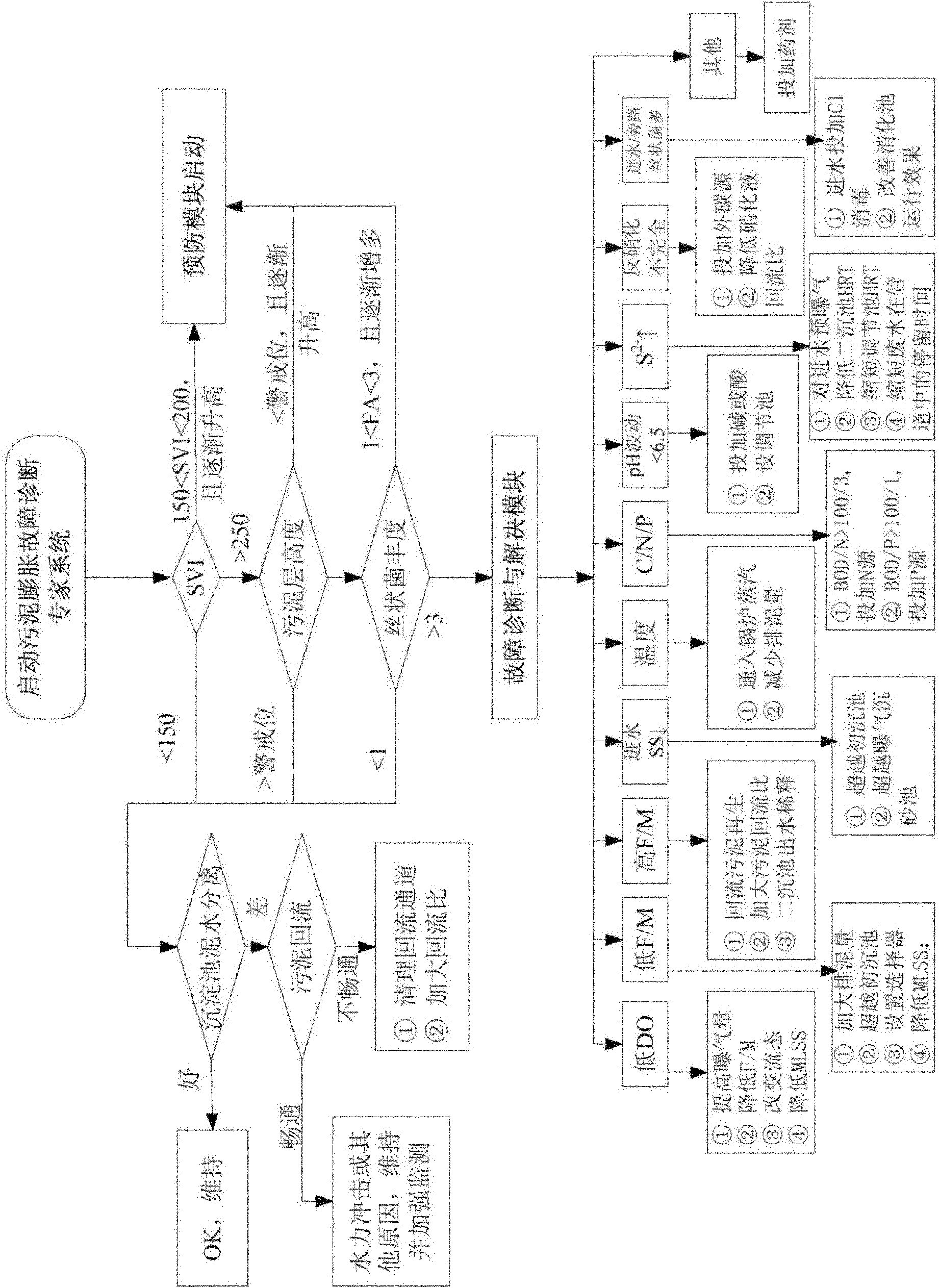

[0044] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the method for diagnosing sludge bulking based on the operating parameters of the sewage treatment plant stored in the knowledge base module 1 includes sludge sedimentation index SVI, filamentous bacteria index , the height of the sludge layer, the concentration of suspended solids in the effluent, and whether sludge loss occurs to determine whether sludge bulking occurs; the condition for diagnosing whether sludge bulking occurs in step 4 is: under the condition that filamentous bacteria are found in the microscopic examination , when one or more of the following symptoms occur at the same time, sludge bulking has occurred; the symptoms include: a. The sludge sedimentation index SVI is higher than 250mL / g; b. The bacterial index is higher than 3; c, the height of the sludge layer is close to the warning level; d, the secondary sedimentation tank has obvious sludge loss ph...

specific Embodiment approach 3

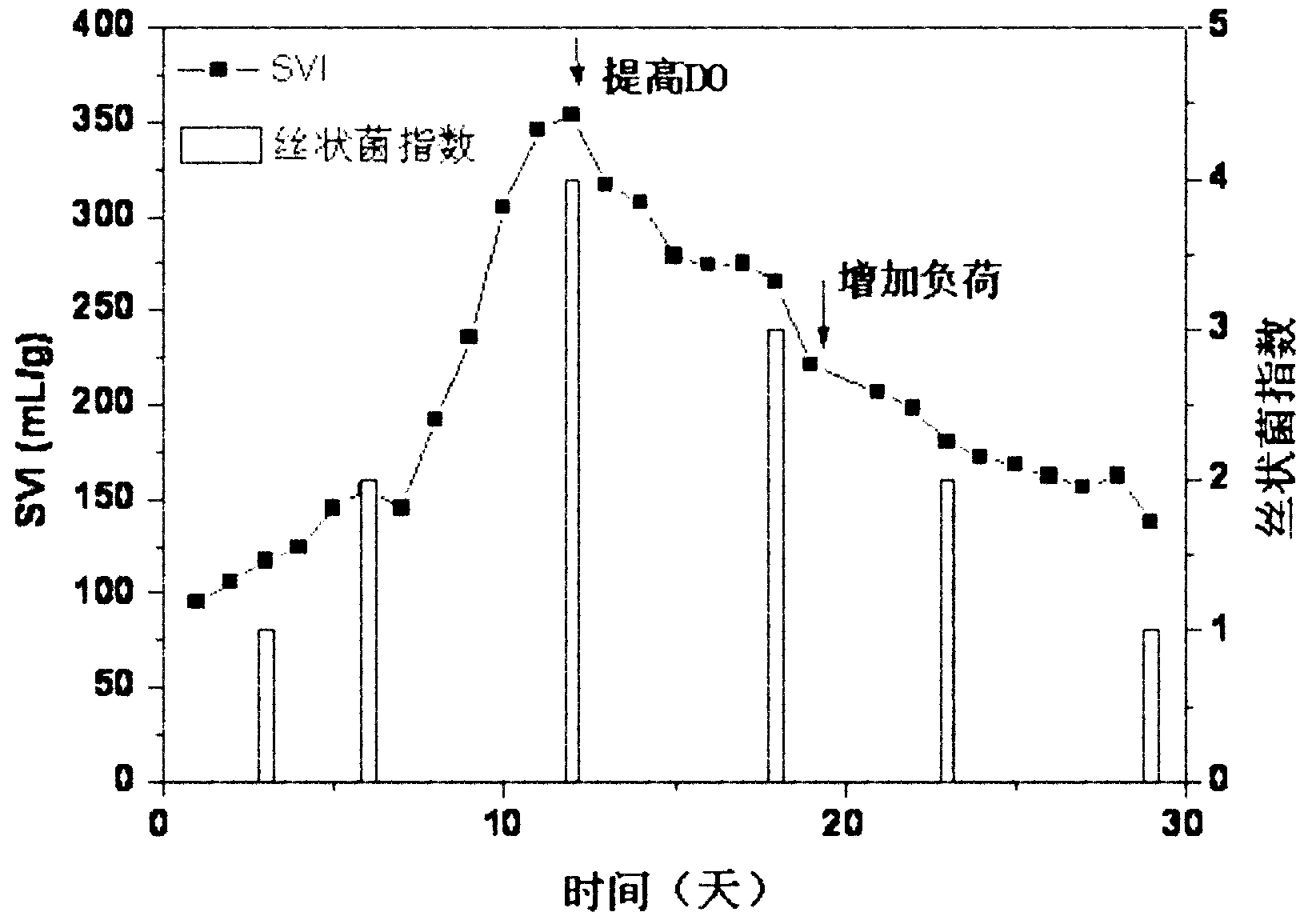

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that when sludge bulking occurs in Step 5, according to the process operation parameters in the sewage treatment system: dissolved oxygen concentration, sludge load range, influent water quality Indicators, effluent water quality indicators, water temperature, sludge return ratio, sludge age, analyze and give the cause of sludge bulking, and provide corresponding solutions and the credibility of the reasoning results. The specific reasons mentioned include sludge bulking caused by low dissolved oxygen, sludge bulking caused by low load, sludge bulking caused by influent C / N / P ratio imbalance, sludge bulking caused by low temperature, and sludge bulking caused by high load. Sludge bulking, sludge bulking caused by high influent sulfide concentration, and sludge bulking caused by low pH. Solutions to sludge bulking include increasing aeration, increasing sludge load, adding nutrients appropriate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com