Corrosion resistance precision gas voltage regulator

A voltage stabilizer, corrosion-resistant technology, applied in gas/liquid distribution and storage, fluid pressure control without auxiliary power, piping systems, etc., can solve the problems of unsuitable long-term stable use, poor long-term operation stability, low accuracy , to achieve the effect of a wide range of pressure applications, stable operation and high pressure adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

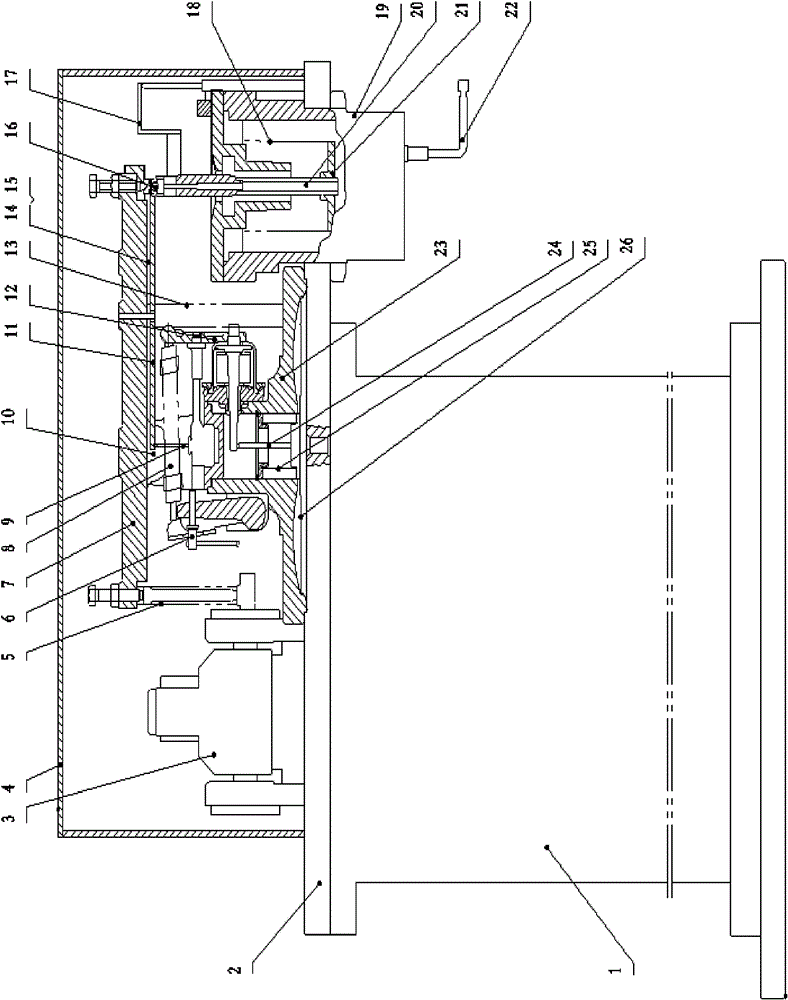

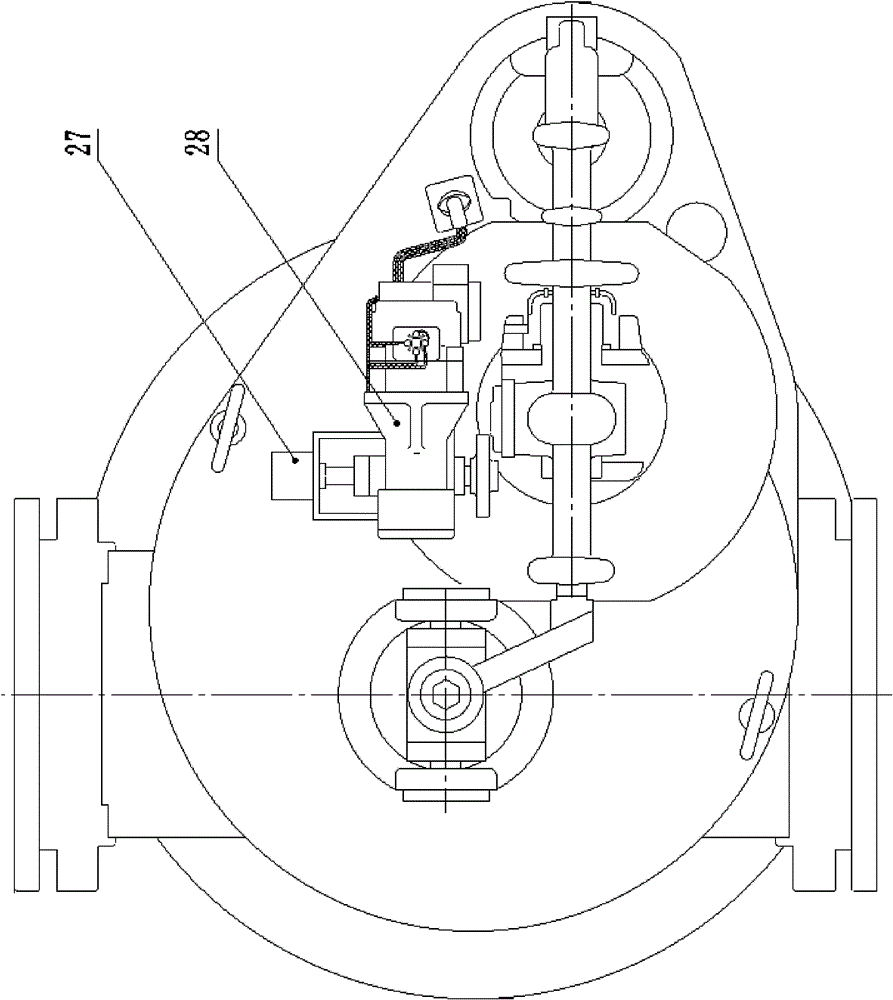

[0025] A corrosion-resistant precision gas regulator according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as Figure 1 to Figure 3 As shown, a corrosion-resistant precision gas regulator of the present invention includes a gas tank 1, the body of the gas tank 1 is cylindrical, a flat plate 2 is fixed above the gas tank 1, and a cover is fixed on the flat plate 2 4. Diaphragm 26, zero chamber cover 23, lower needle rod 24, sensor lever 12, upper needle rod 9, small lever 11, airflow pipe 20, servo device 19, large lever 7 and Rotary fork 3 and other components.

[0027] Two connecting pipes with equal diameters are arranged on the opposite position of the gas tank 1 , one is a gas input pipe 34 and the other is a gas output pipe 30 . The standard valve seat 33 is assembled on the gas input pipe 34 (or gas output pipe 30), the valve seat 33 is equipped with valves 32 of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com