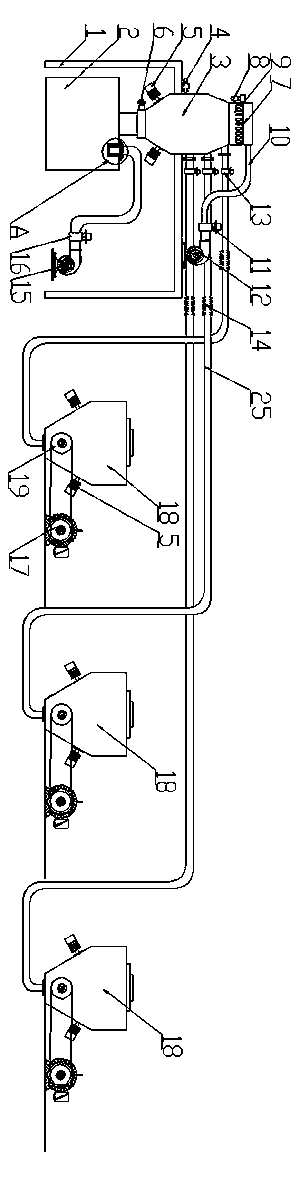

Novel automatic feeding system

A new type of automatic feeding technology, applied in mixers, dissolving, chemical instruments and methods, etc., can solve problems such as human injury, poor work site environment, and heavy labor, and achieve reduced labor intensity, novel structural design, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

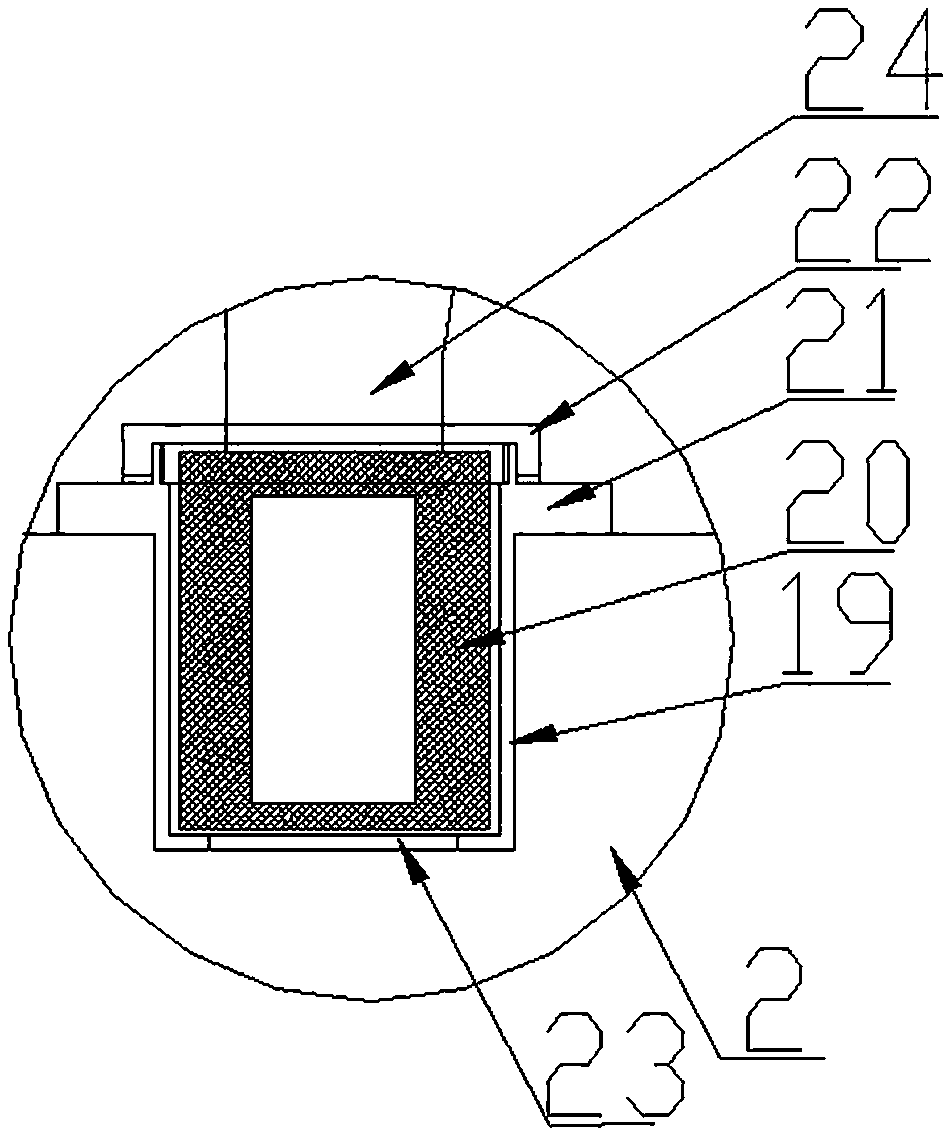

[0017] Under the premise that the ratio of the three basic materials is set, first turn on the stirring drive motor 17 on one of the sub-storage bins 18 to drive the stirring shaft 19 to stir the materials in the sub-storage bin 18, and the feed pneumatic valve 13 is opened. At this time, the negative pressure fan 12 and the first negative pressure supplementary gas switch 11 are turned on, the material enters the mixed storage silo 3 from the sub-storage 18, and the dynamic metering pump 4 starts to measure and feeds into the pneumatic valve when the required weight is reached 13 is closed, the stirring drive motor 17 is closed; the first pneumatic discharge valve 6 at the interface of the high mixer 26 is opened, and the pneumatic hammers 5 on the left and right sides of the bottom of the mixing storage bin 3 are opened. The above actions can ensure mixed storage All materials in the bin 3 can be dropped into the high mixer to ensure accurate feeding; after the above actions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com