Collision atomization stream-extrusion combustion system of internal-combustion engine

A combustion system and internal combustion engine technology, applied in the direction of internal combustion piston engines, charging systems, combustion engines, etc., can solve the problems of short penetrating distance of umbrella-shaped spray, too thick circular distribution of mixed gas, uneven distribution, etc., and achieve fast spray dispersion speed , uniform distribution, NOx reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

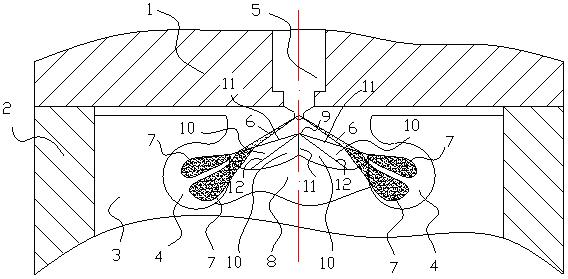

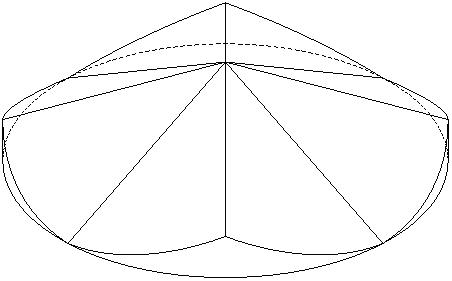

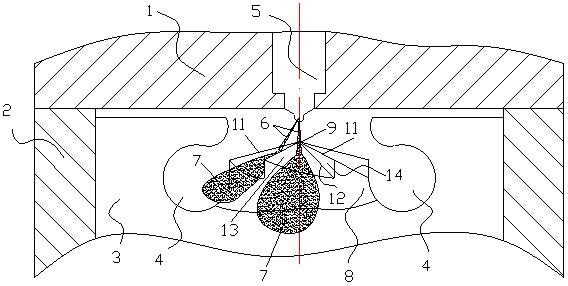

[0016] exist figure 1 , 2 , In the embodiment shown in 3, 4, this collision spray squish flow combustion system mainly has a combustion chamber 4 that is made up of cylinder head 1, cylinder liner 2 and piston 3, and fuel injection nozzle 5 uses multi-beam mode to inject high-pressure fuel It is sprayed into the combustion chamber 4 in the form of mist to form a combustible mixture, and a protrusion 8 is provided in the center of the piston 3 . The protrusion 8 is made up of fan surfaces radially and continuously distributed with the convex top 9 as the center, each fan surface forms an intersecting top edge 11 with the adjacent side folding fan surface, and forms an intersecting top edge 11 with the adjacent other side folding fan surface. The bottom edge 12; the fuel injection nozzle 5 is located above the convex top 9.

[0017] figure 1 , 2 An embodiment is shown, figure 2 yes figure 1 A three-dimensional schematic of the middle bump 8. The center of the piston 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com