Alloy wire for connecting semiconductor components

A semiconductor and alloy wire technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as uneven loops, easy bending of lead frames, and bonding problems between alloy wires and lead frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

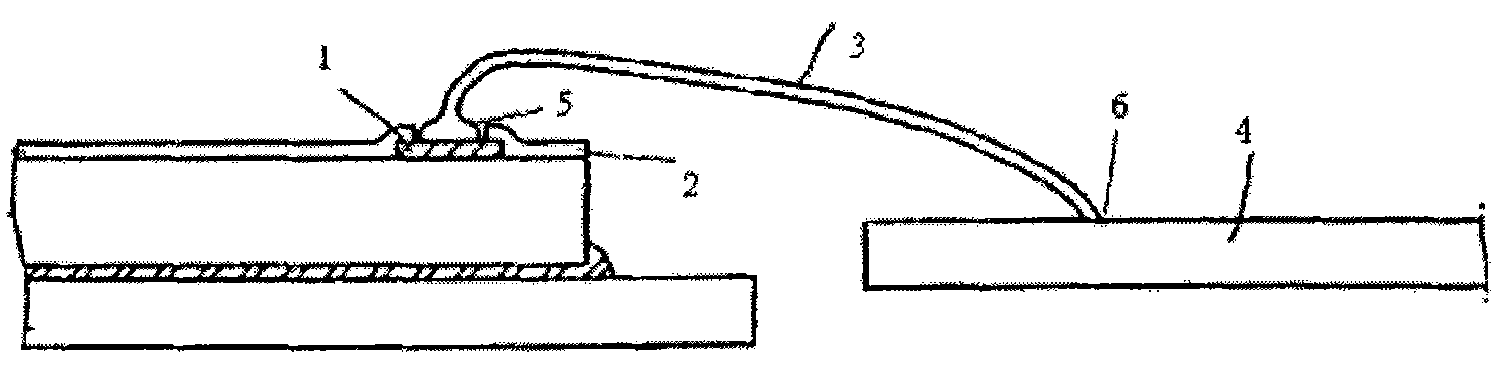

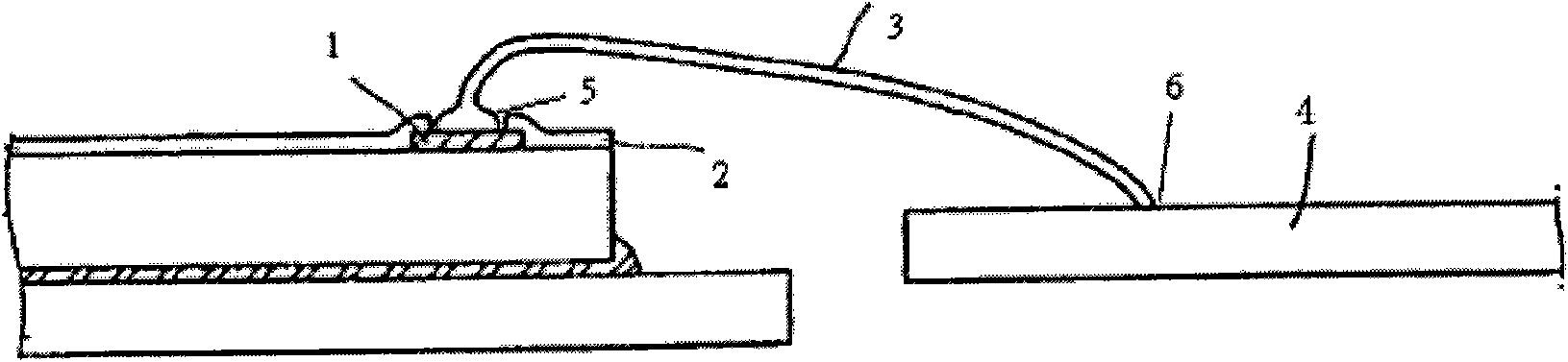

Embodiment Construction

[0019] In the following examples, the preparation method is as follows: Add a certain amount of other elements to high-purity silver with a purity of 99.999% (weight percent), and after vacuum melting, cast an alloy rod with the indicated composition, and roll, wire draw Machine cold forming and intermediate annealing, and finally cold forming into a thin wire with a diameter of 18 μm and final annealing to achieve an elongation of 10-15%. Using the automatic wire bonding machine model 1488 of K&S Company, the alloy wire is bonded between IC, LED chip Al, Au electrode and copper alloy lead frame at a heating temperature of 100 ° C by using ultrasonic combined hot pressing method. For bonding work, make a bonding sample of 100 pins. Then, after sealing the sample with epoxy resin, a thermal cycle test of -20°C x 30 minutes and 180°C x 30 minutes was carried out one hundred times.

[0020] (1) 0.4-15% by weight of gold (Au), at least one of 0.2-5% by weight of palladium (Pd) or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com