Hydrogenation method for improving yield of bisphenol-A type hydrogenated epoxy resin

A technology of propanediol-type epoxy resin and hydrogenated epoxy resin is applied in the field of preparation method of propanediol-type hydrogenated epoxy resin, which can solve the problems of low yield, easy decomposition of epoxy groups, and high hydrogen consumption, and achieves the The effect of high yield, improved contact efficiency, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

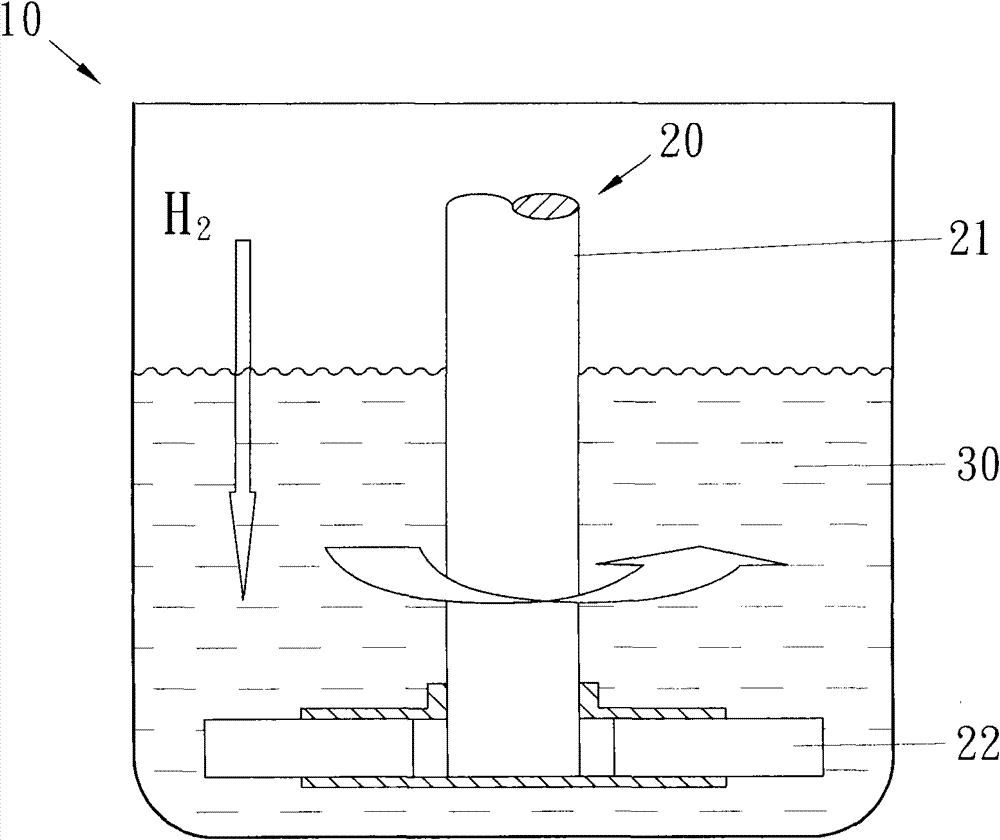

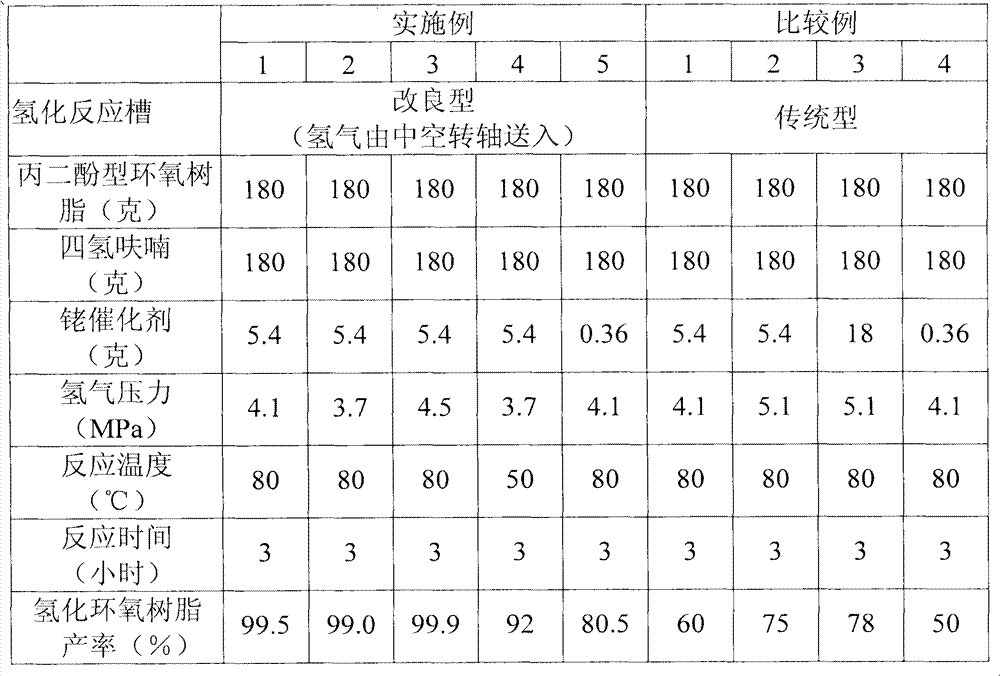

Embodiment 1

[0051] Get 180 grams of propanediol type epoxy resin and dissolve in 180 grams of tetrahydrofuran (THF), put into a volume of 0.5 liters and be provided with a pressure-resistant reaction tank of a pilot gas stirrer, then add 5.4 grams of rhodium catalysts, and then add hydrogen to 4.1MPa Then keep constant pressure. Then start the pilot gas stirrer of the reaction tank, make the hollow rotating shaft reach 1000 revolutions per minute, then increase the temperature to 80 degrees Celsius, and then react at 80 degrees Celsius for 3 hours. After the reaction was completed, the reaction solution was cooled to room temperature, and the catalyst and tetrahydrofuran were removed by filtration, and the composition of the reaction product was analyzed. As shown in Table 1, the yield of propanediol type hydrogenated epoxy resin was 99.5%.

Embodiment 2

[0053] With embodiment 1, hydrogen pressure is changed into 3.7MPa, and other conditions are all the same. The results are shown in Table 1, and the yield of propanediol type hydrogenated epoxy resin was 99.0%.

Embodiment 3

[0055] With embodiment 1, hydrogen pressure is changed into 4.5MPa, and other conditions are all the same. The results are shown in Table 1, and the yield of propanediol type hydrogenated epoxy resin was 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com