Rare earth complex coated with silicon dioxide and preparation method of rare earth complex

A technology of rare earth complexes and silica, applied in the field of rare earth complexes, can solve problems such as affecting the fluorescence properties of rare earth complexes, and achieve the effects of solving stability, improving stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Rare earth complex Eu(TTA) 3 Preparation of phen

[0034] Will Eu 2 o 3 (purity 99.99%) dissolved in dilute hydrochloric acid, cooled after slow evaporation, white crystal EuCl precipitated 3 ·6H 2 O, put into desiccator after filtering and dry for subsequent use. 1mmol EuCl 3 .6H 2 O and 3 mmol of 2. Thiophene trifluoroacetylacetone (TTA) was dissolved in 20 mL of absolute ethanol. Then, 3 mmol of triethylamine (0.42 mL) was added. Finally, 1 mmol of phenanthroline (phen) was added, and a white precipitate was formed. After stirring for 0.5 h, the precipitate was suction-filtered, washed with absolute ethanol for several times, and then suction-filtered again, and put into a desiccator to dry for later use.

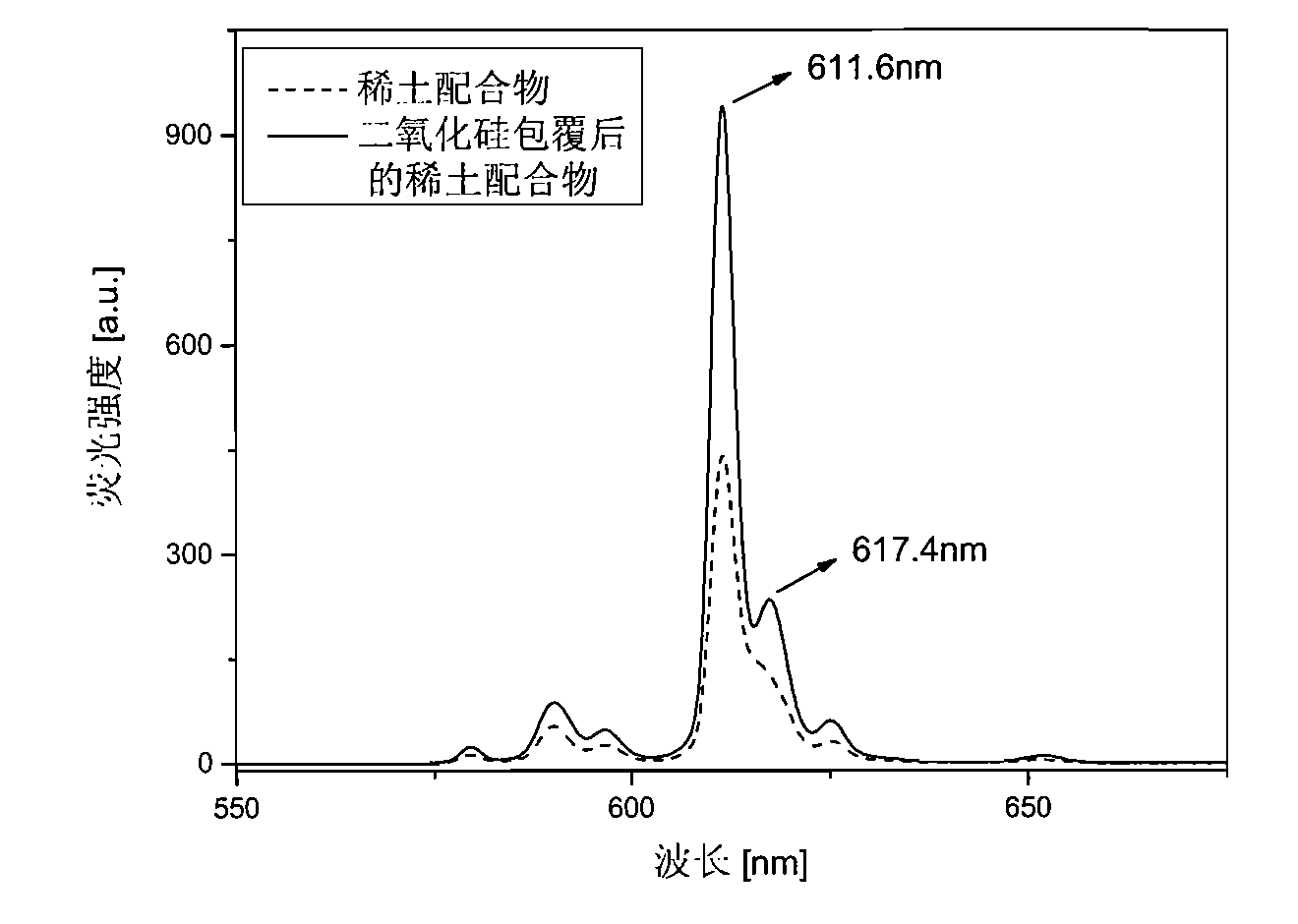

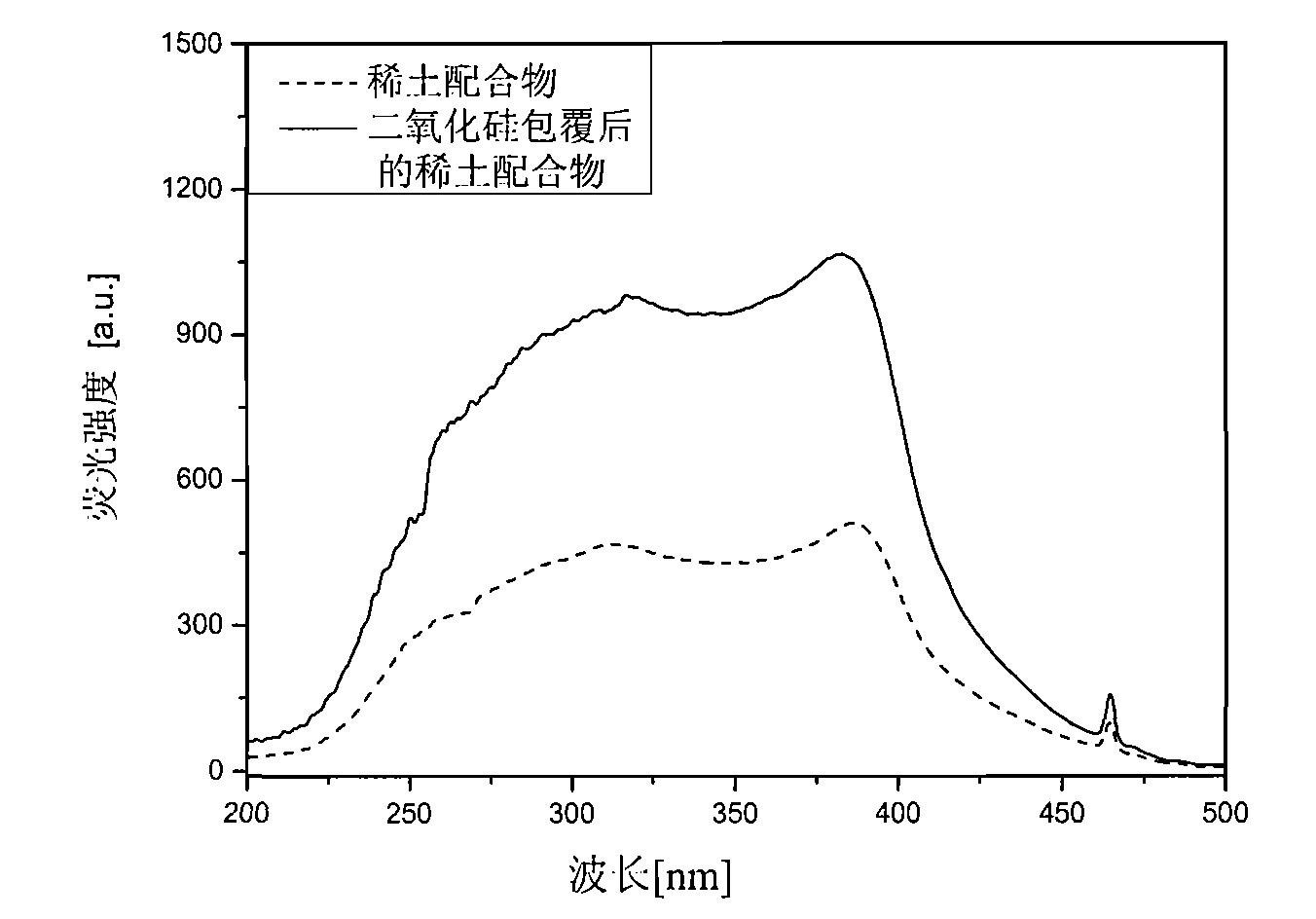

[0035] The 2 elemental analysis results of the sample are shown in Table 1, and Eu(TTA) 3 The theoretical value calculated by phen is consistent; its emission spectrum at an excitation wavelength of 383nm is as follows figure 1 As shown, the excitation ...

Embodiment 2

[0039] SiO2 Coated Rare Earth Complex SiO 2 / Eu(TTA) 3 Preparation of phen

[0040] 0.2g of Eu(TTA) 3 phen and 2 mL of TEOS were dispersed in 20 mL of isopropanol. The solution was placed in a sonicator for ultrasonic treatment for 1 h, then the solution was transferred to a flask for electric stirring, and the stirring rate was maintained at 3000 n / min. Add 1 mL of ammonia water (28%), 1 mL of deionized water and 5 mL of isopropanol mixture into the flask at one time, continue to stir for 20 h, then centrifuge the product and wash it several times with isopropanol. The product was dried at 80°C for 12 hours to obtain the final product.

[0041] The mass of the final product was weighed to be 0.3 g. This shows that about 0.1g is due to the silica coated in Eu(TTA) 3 phen surface results.

[0042] The secondary elemental analysis results of this final product are shown in Table 2, and its C, H, N element content ratio Eu(TTA) 3 The corresponding value in phen has been r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com