Tea stem particle board and production process thereof

A production process and particle board technology, which is applied to other household appliances, wood processing appliances, household components, etc., can solve the problems of discarding and waste of tea stems, and achieve the effect of reasonable product structure, excellent performance and saving wood resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of production process step of tea stem particle board is:

[0040] 1) Dry the tea stalks at a drying temperature of 80°C, control the moisture content of the dried tea stalks at 10%, and pulverize them to form broken tea stalks with a particle size of 20-120 meshes;

[0041] 2) Evenly mix the pulverized tea stalk fragments with the adhesive modified urea-formaldehyde resin to form a mixture; the concentration of the adhesive is 65%, and the sizing amount is 12% of the weight of the tea stalk;

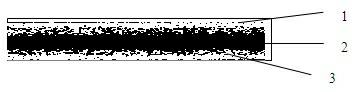

[0042] 3) Paving and forming: According to the requirements of the structure design of the tea stalk scrap board, according to the needs of the low density, medium density and high density of the board, the tea stem scrap after sizing can be paved and withdrawn several times to a thickness specification of 200mm Particle slabs of multi-layer structure can also be formed by mechanical or air-laid forming equipment.

[0043] 4) Pre-pressing: the unit pressure of slab pre-pr...

Embodiment 2

[0053] A kind of production process step of tea stem particle board is:

[0054] 1) Dry the tea stalks at a drying temperature of 130°C. The dried tea stalk scraps are controlled at 3%, and crushed to form tea stalk scraps. The particle size of the tea stalk scraps is 20-120 mesh.

[0055] 2) Evenly mix the pulverized tea stalk fragments with the adhesive melamine resin to form a mixture, the concentration of the adhesive is 55%, and the sizing amount is 10% of the weight of the tea stalk;

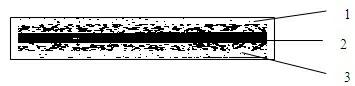

[0056] 3) Paving and forming: According to the requirements of the structure design of tea stalk scrap slabs, and according to its high-density requirements, the tea stalk scrap after sizing can be evenly spread and withdrawn into a single-layer scrap slab with a thickness of 100mm.

[0057] 4) Pre-pressing: make the slab of tea stalk scraps have a certain degree of compactness, which is convenient for slab transportation and cutting, etc. The unit pressure of slab pre-pressing is 1.0 MPa,...

Embodiment 3

[0067] A kind of production process step of tea stem particle board is:

[0068] 1) Drying the tea stalks at a drying temperature of 100°C, controlling the moisture content of the dried tea stalk scraps to 7%, and pulverizing them to form tea stalk scraps;

[0069] 2) Evenly mix the crushed tea stalk fragments with the adhesive isocyanate resin to form a mixture, the concentration of the adhesive is 45%, and the sizing amount is 5% of the weight of the tea stalk;

[0070] 3) Paving and forming: According to the requirements of the structure design of the tea stalk scrap board, according to the needs of the low density, medium density and high density of the board, the tea stem scrap after sizing can be paved and withdrawn several times to a standard thickness of 150mm Particle slabs of graded structure can also be formed by mechanical or air-laid forming equipment.

[0071] 4) Pre-pressing: Make the slab of tea stalk scraps have a certain degree of compactness, which is conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com