Brazing filler metal for high-frequency induction brazing of aluminum steel and brazing method of brazing filler metal

A technology of high-frequency induction brazing and brazing materials, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of thermal conductivity and other physical properties difference, weld inclusions, etc., to avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

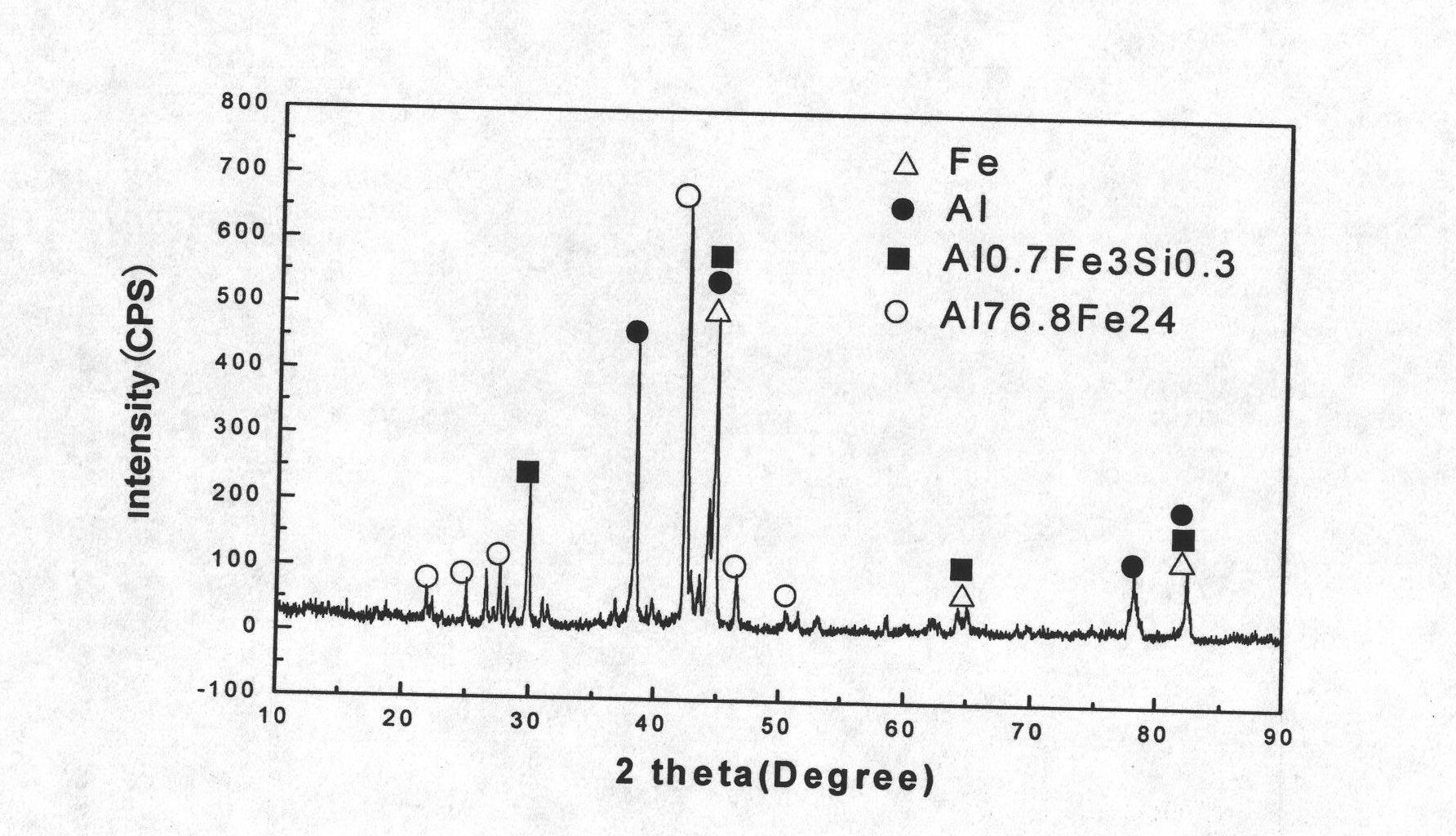

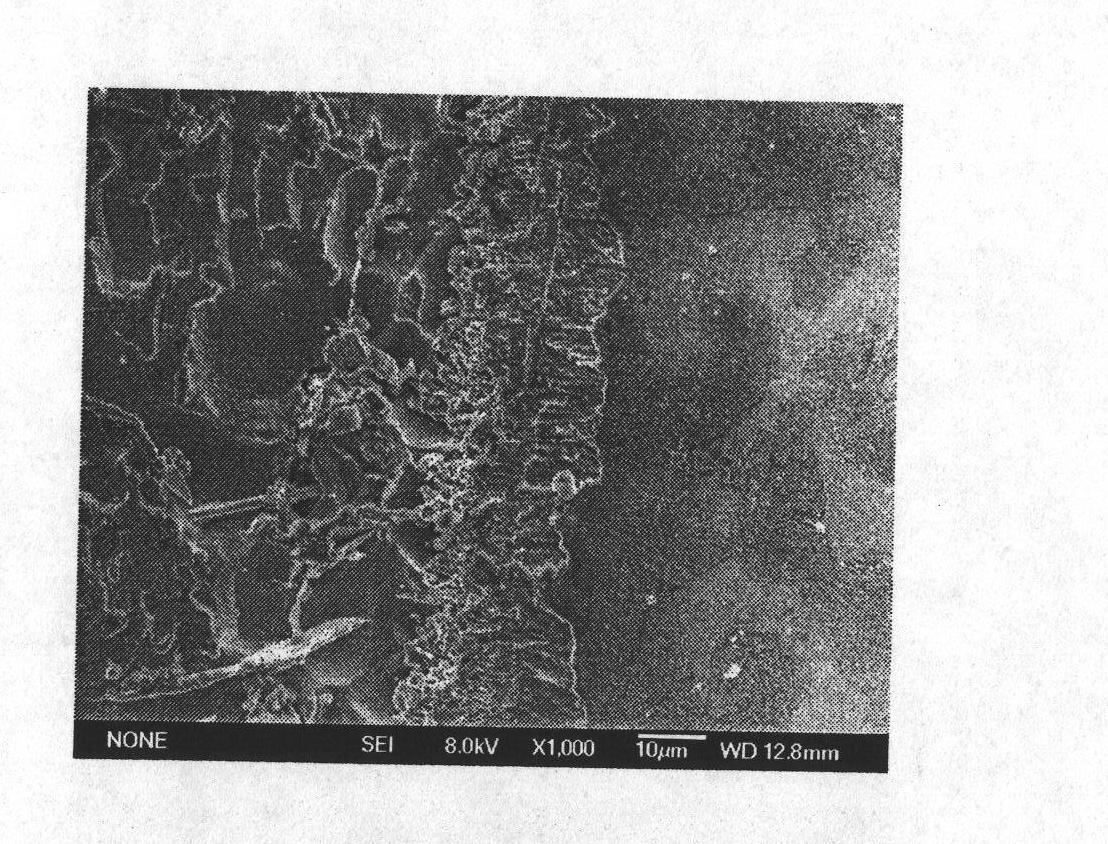

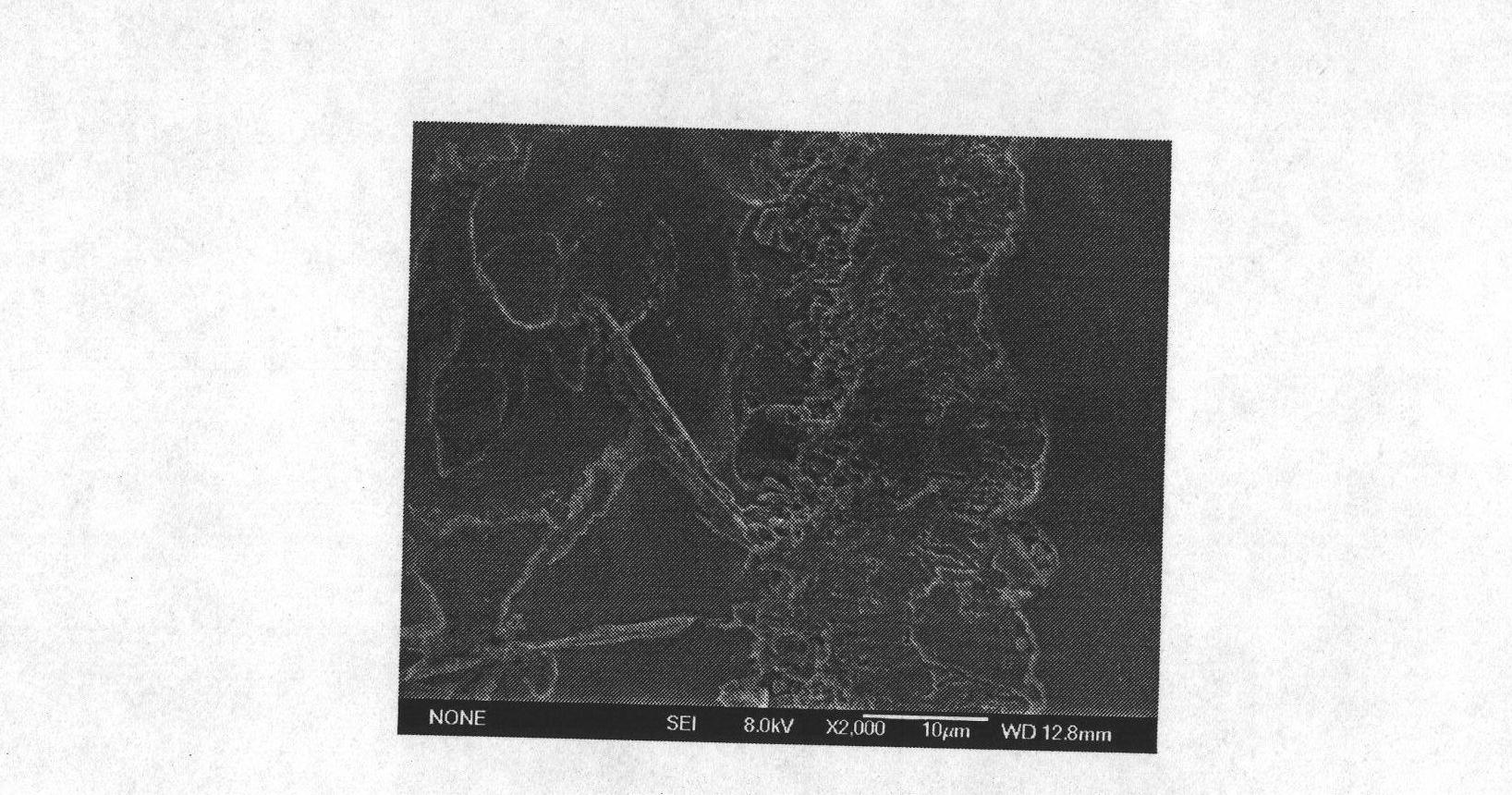

[0009] The invention relates to a brazing material for high-frequency induction brazing of aluminum steel and a brazing method, wherein the brazing material for high-frequency induction brazing of aluminum steel uses Al-Si-based alloy powder as the brazing material component of the solder, and the brazing material alloy The particle size is -150~+300 mesh, the melting point is 570~580℃; three kinds of fluoride salts KF, NaF and AlF are selected 3 As a flux, its ratio is (KF, NaF): AlF 3 = 1: 10); Potassium tartrate is selected as the binder; the solder content in the solder is 60%, the brazing flux content is 38-39%, and the binder accounts for 1%-2%.

[0010] Aluminum steel high-frequency induction brazing method, prepare each component according to the above, make a paste with absolute ethanol, remove the oxide film on the surface of the steel and aluminum workpiece to be brazed, and then clean it with acetone; Evenly coat the adjusted solder on the welding surface and pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com