Welding method for welding columns of encapsulated integrated circuit (IC)

A welding method and integrated circuit technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as crack expansion in the soldering layer, open circuits, and the impact on the quality of device interconnections, so as to improve the yield and improve the quality. Effect

Active Publication Date: 2013-01-16

WUXI ZHONGWEI GAOKE ELECTRONICS +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned assembly method often has micro-encapsulated air bubbles on the welding surface, which affects the strength of the soldering column welding of packaged products, and the temperature change is likely to cause cracks in the soldering layer to expand, which will affect the quality of device interconnection and even lead to open circuits.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

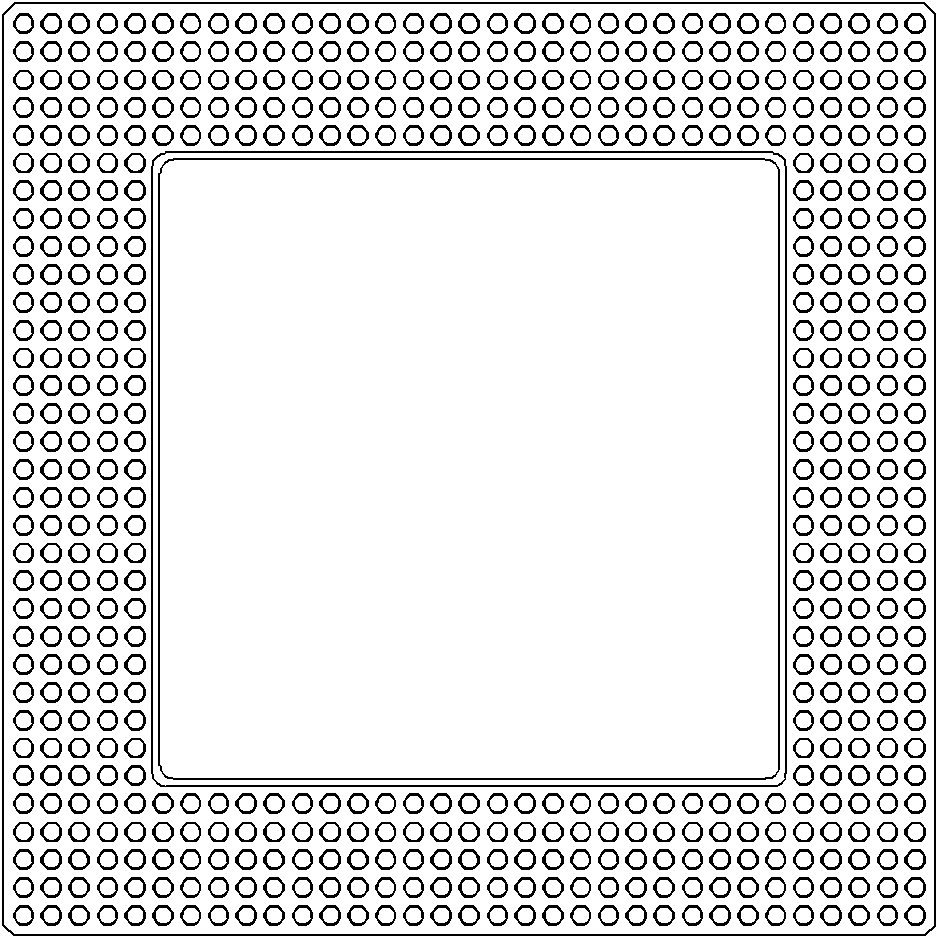

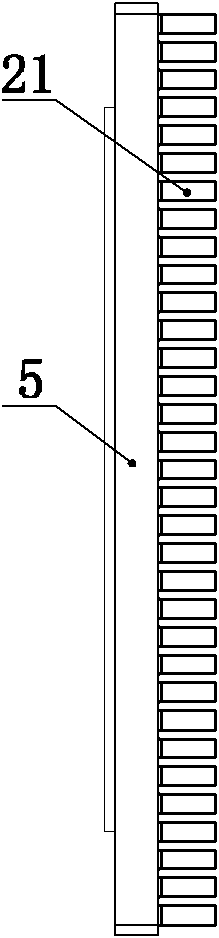

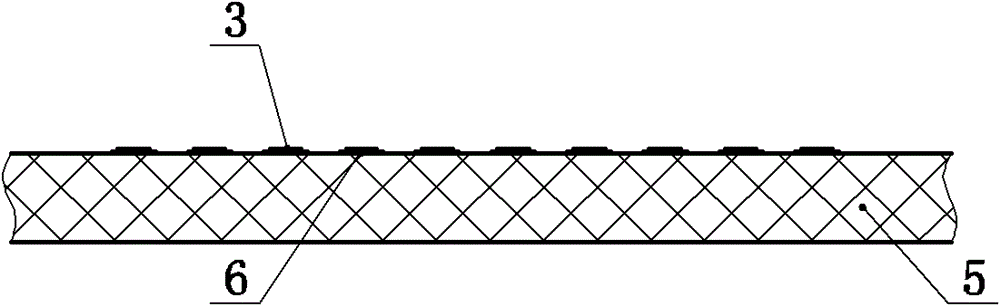

The invention relates to a welding method for welding columns of an encapsulated integrated circuit (IC). The welding method is characterized by comprising the following steps: tidily arranging the welding columns in a die; forming a convex welding flux on a pad of a column base plate to be embedded; placing the welding columns and the die in the pad which corresponds to a CLGA560 circuit of the column base plate to be embedded and is provided with the convex welding flux, and transferring the pad into a reflow oven so as to complete welding; and after completion of the welding operation, washing and drying. The welding method has the advantages that by virtue of factors of the convex welding flux such as point contact, solder fusing, surface tension and the like, micro-bubbles are avoided in fusion of the welding flux and an end surface so as to obtain a high-quality welding column encapsulated device without micro-bubbles on a welded surface, which solves the problem of the encapsulated micro-bubbles on the welded surface of the welding columns, saves the step of performing X-ray or ultrasonic inspection on the device so as to ensure the welding quality in the conventional welding process, and improves welding quality and welding yield.

Description

technical field [0001] The invention relates to a welding process for integrated circuit packaging pins, in particular to a welding post welding method for packaging integrated circuits, which belongs to the technical field of integrated circuit manufacturing. Background technique [0002] With the increase in the number of I / O terminals of semiconductor integrated circuit devices and the increase in packaging density, the packaging terminals are arranged in area arrays, such as ball grid arrays (BGA) and column grid arrays (CGA), and the pitch is getting more and more The smaller (2.54mm→1.27mm→1.00mm→0.80mm→...). [0003] The process method of using welding pillars to assemble and weld the required column grid array (CGA) package mainly uses printing solder paste such as silk screen or stainless steel plate or distributes solder paste with precision dispensing process, and then puts the welding pillars into the mold or puts them into the mold. After the overall welding po...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L21/60

Inventor 丁荣峥杨兵张顺亮

Owner WUXI ZHONGWEI GAOKE ELECTRONICS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com