System for reutilizing bromomethane by vacuum heating

A technology of vacuum heating and methyl bromide, applied in the field of chemical treatment, can solve the problems of high air tightness requirements of equipment, low purity of methyl bromide, poor desorption effect of methyl bromide, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

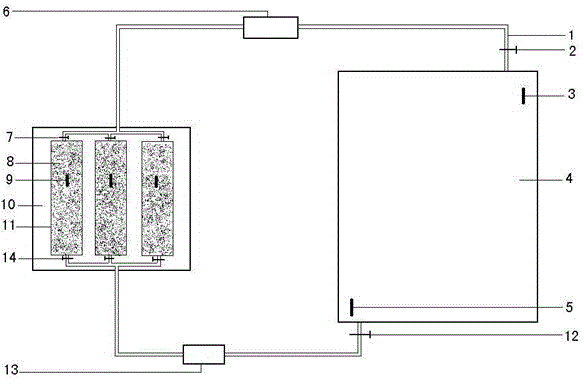

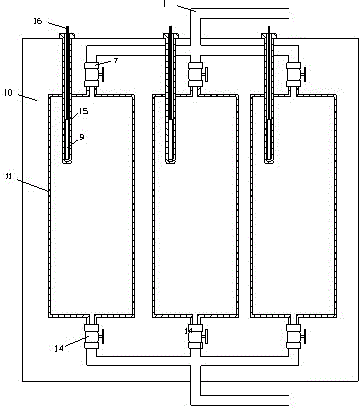

[0019] refer to figure 1 , the system includes: high temperature resistant, methyl bromide corrosion resistant pipeline 1, valve A2, valve B7, valve C12 and valve D14, methyl bromide concentration detector A3 and methyl bromide concentration detector B5, fumigation storehouse (or other fumigated closed facilities) 4 , vacuum pump 6, activated carbon or carbon fiber 8, temperature probe 9, heating chamber 10, carbon material filled column 11, circulation fan 13. Wherein, valve A2 and valve C12 are closed, and after fumigation treatment with methyl bromide in the fumigation storehouse (or airtight fumigation facility) 4, valve A2 and valve C12 are opened, and carbon material filled column valve D14 and valve B7 are opened at the same time, through circulation fan 13 And the pipeline 1 fully passes the methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com