Sewing machine needle clamp with replaceable yarn passing plate

A thread-passing board and sewing machine technology, which is applied to sewing machine components, thread-pulling hooks for sewing machines, sewing equipment, etc., can solve problems such as abnormal structural separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The detailed description and technical contents of the present invention are described as follows with respect to the accompanying drawings.

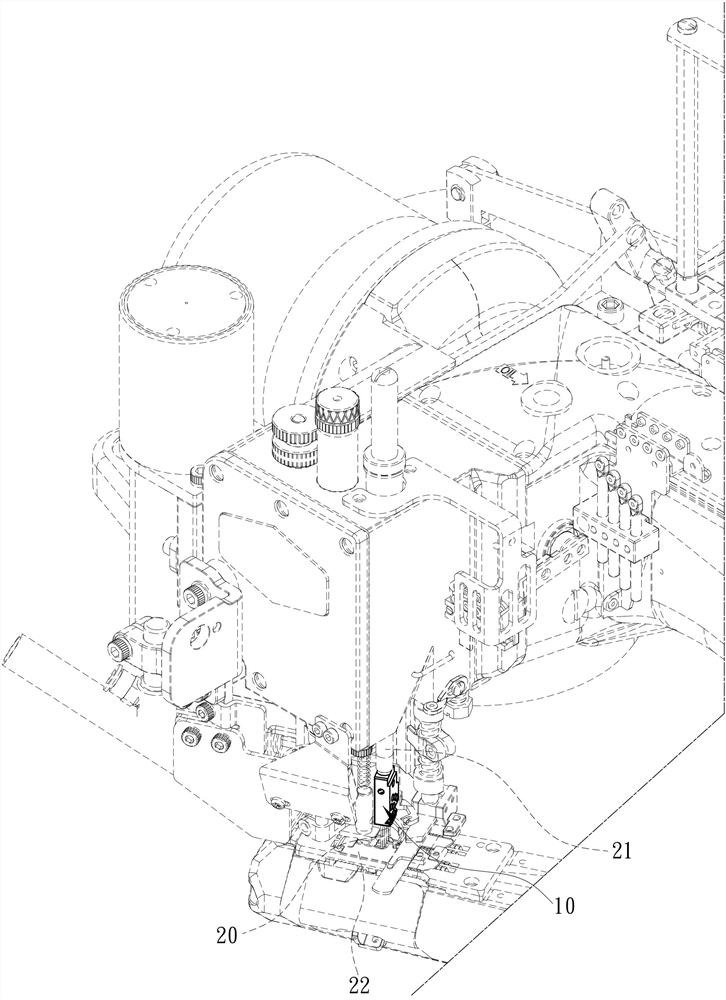

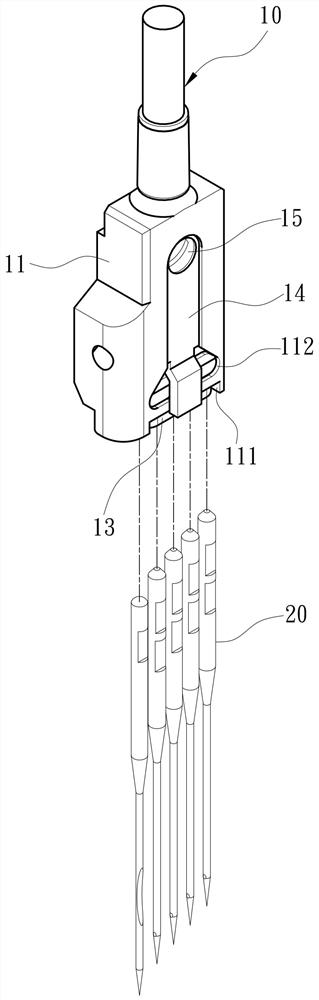

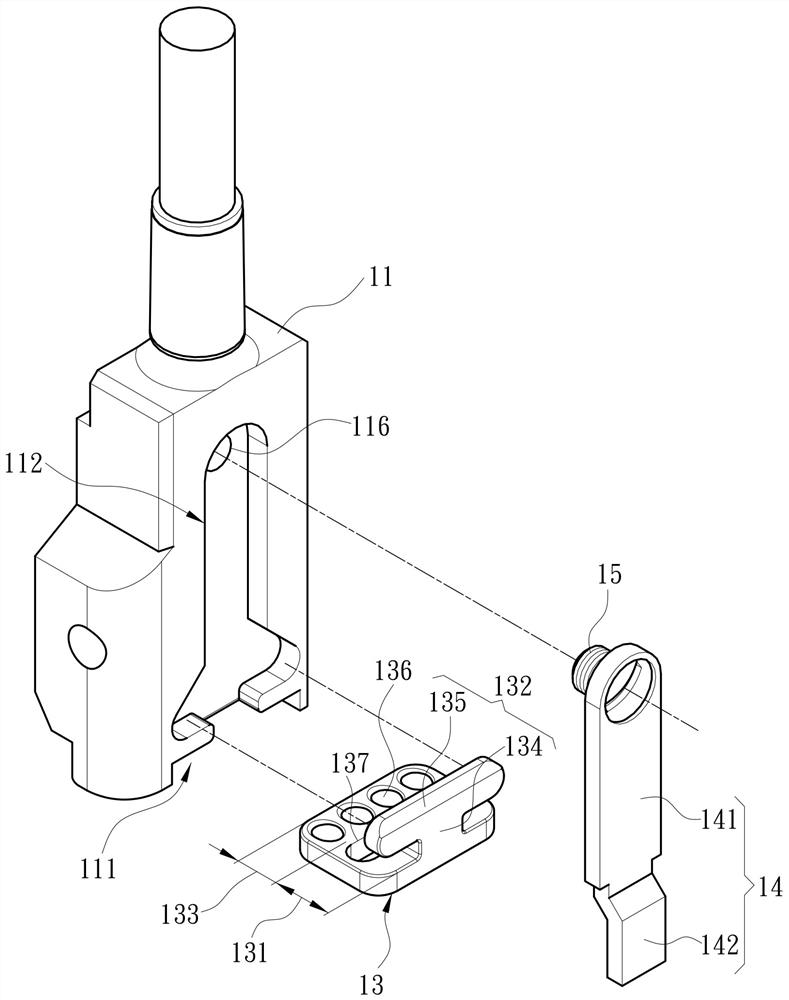

[0022] see figure 1 The present invention provides a sewing machine needle 10 with a replaceable thread guide plate. The sewing machine needle 10 is provided with a plurality of sewing needles 20 assembled on it, and can be driven by a needle drive rod 21 to produce reciprocating motion. see Figure 1 to Figure 7 The sewing machine needle 10 includes a needle body 11 that can be combined with the needle drive rod 21, a thread passing plate 13 and a pressure plate 14, the needle body 11 has a first groove 111 at one end, And a second groove 112 arranged on the side of the needle body 11 not facing at least one yarn and communicating with the first groove 111 . Further, the first groove 111 is located on the side of the needle body 11 not connected to the needle driving rod 21 , that is, the side facing a sewing machine presser f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com