Soap film flowmeter

A flowmeter and soap film technology, which is applied in the direction of volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure, so as to achieve the effect of expanding the measurement range and simple and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

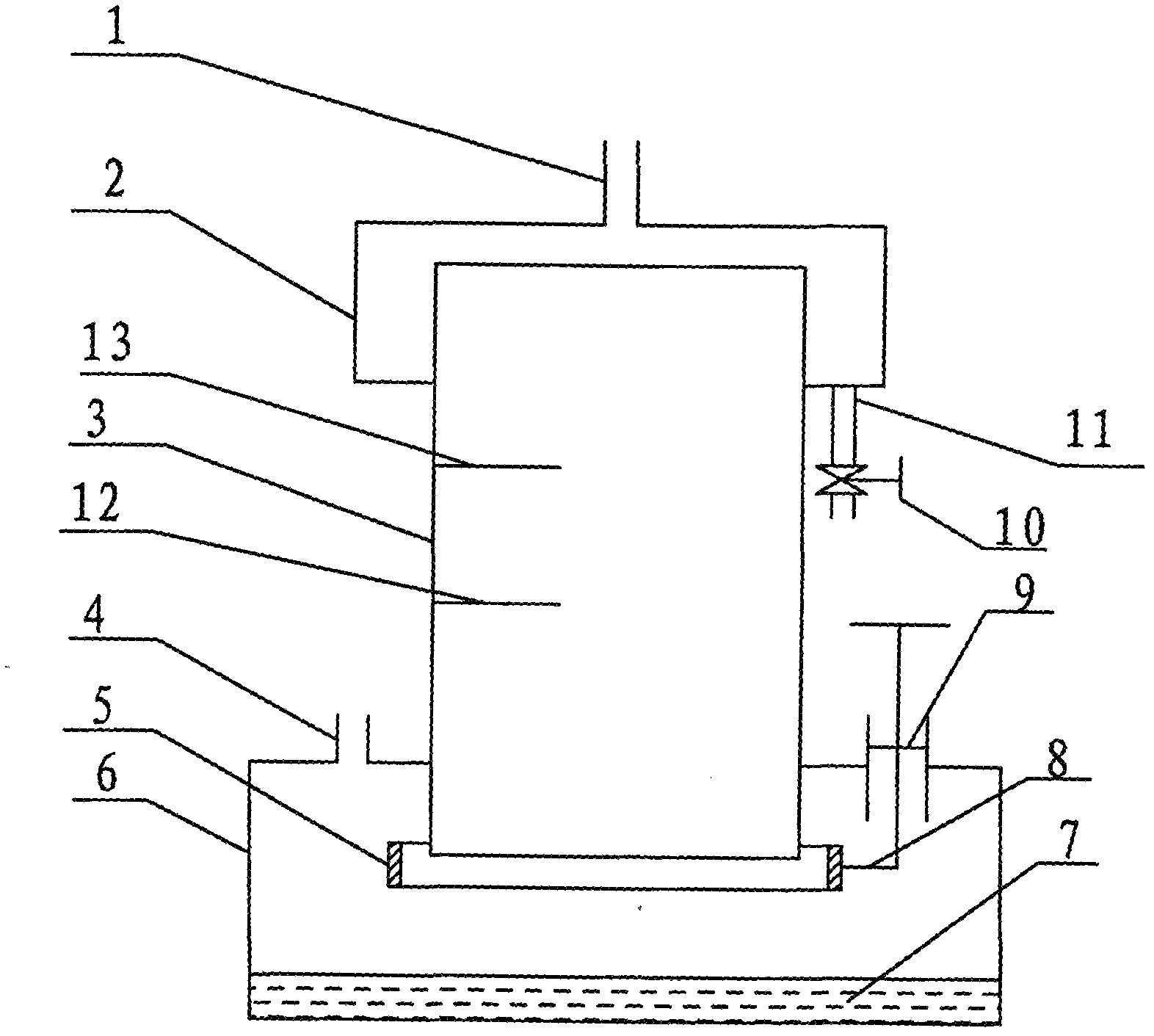

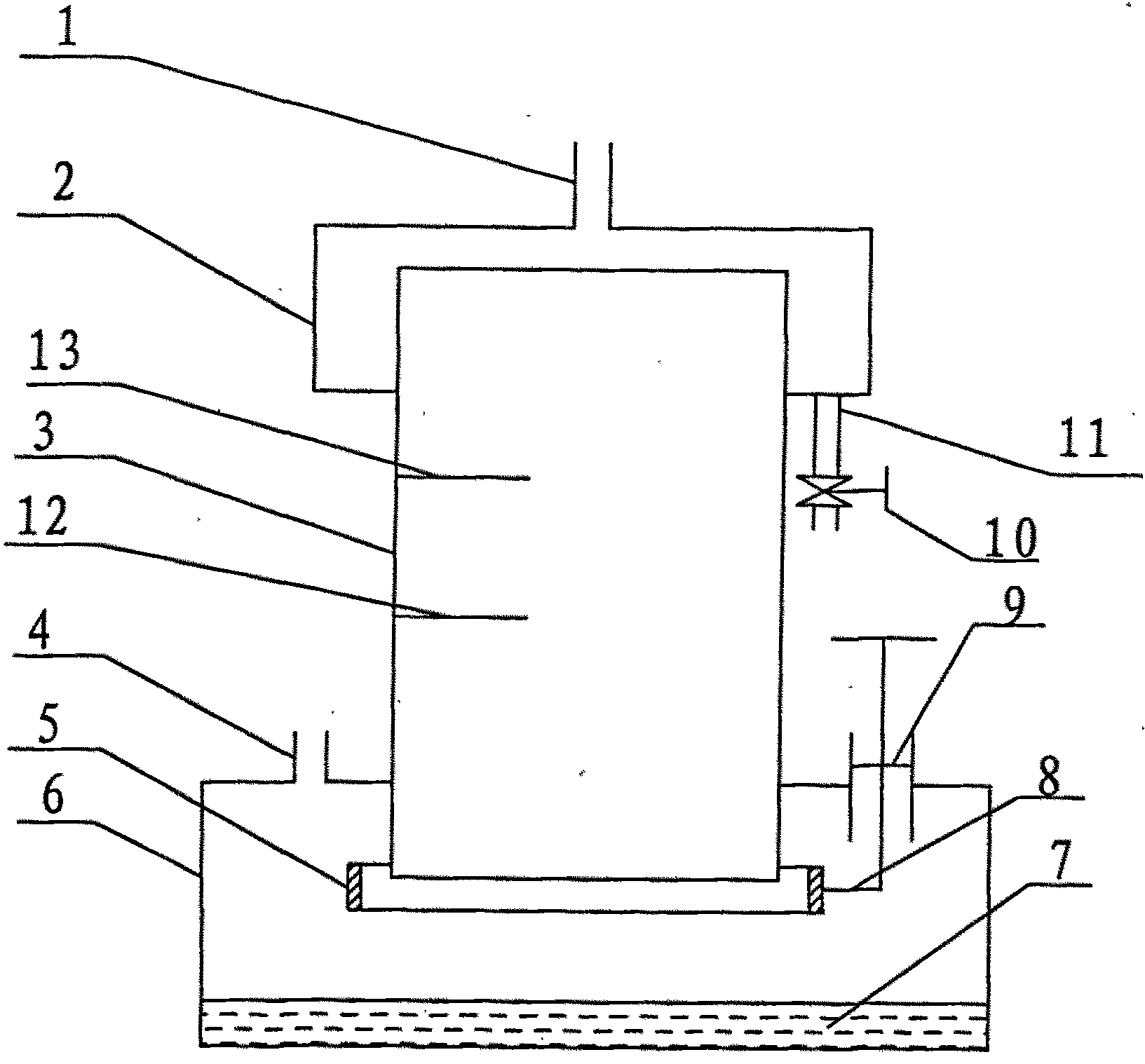

[0017] Such as figure 1 As shown, the soap film flowmeter includes soap liquid 7 and a soap film liquid recovery device 2, a soap film pipe 3, a soap film production device 5, a soap liquid cup 6, a connecting rod 8, a connecting rod sealing device 9. A valve 10.

[0018] The top of the soap film pipe 3 is socketed and sealed with a soap film liquid recovery device 2. The soap film liquid recovery device 2 is a drum with a diameter greater than the soap film pipe 3, and an air outlet 1 is arranged on its upper surface. The center is provided with a circular hole whose diameter is adapted to the outer diameter of the soap film tube 3, and the soap film tube 3 passes through the circular hole into the inside of the soap film liquid recovery device 2 but does not contact the upper surface of the soap film liquid recovery device 2; There is also a soap outlet 11 on the outer side of the lower surface of the membrane liquid recovery device 2 , and a valve 10 is arranged on the soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com