Cruciform reinforcement joint

A cross-shaped, steel bar technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of low work efficiency, easy to affect the construction period, brittle welding points, etc., to achieve a simple manufacturing process, reduce labor, and large bearing capacity. Effect

Inactive Publication Date: 2011-08-10

张鑫犇 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the construction conditions at the welding site are poor, there are many interference factors, and the work efficiency is low, which is easy to affect the construction period, and the welding points are brittle and easy to break

And the binding effect is poor

Although the threaded connection is easy to operate and has a good force effect, it is only for the connection of steel bars in the same direction, and there is nothing that can be done when there are vertical steel bars that need to be connected to each other.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

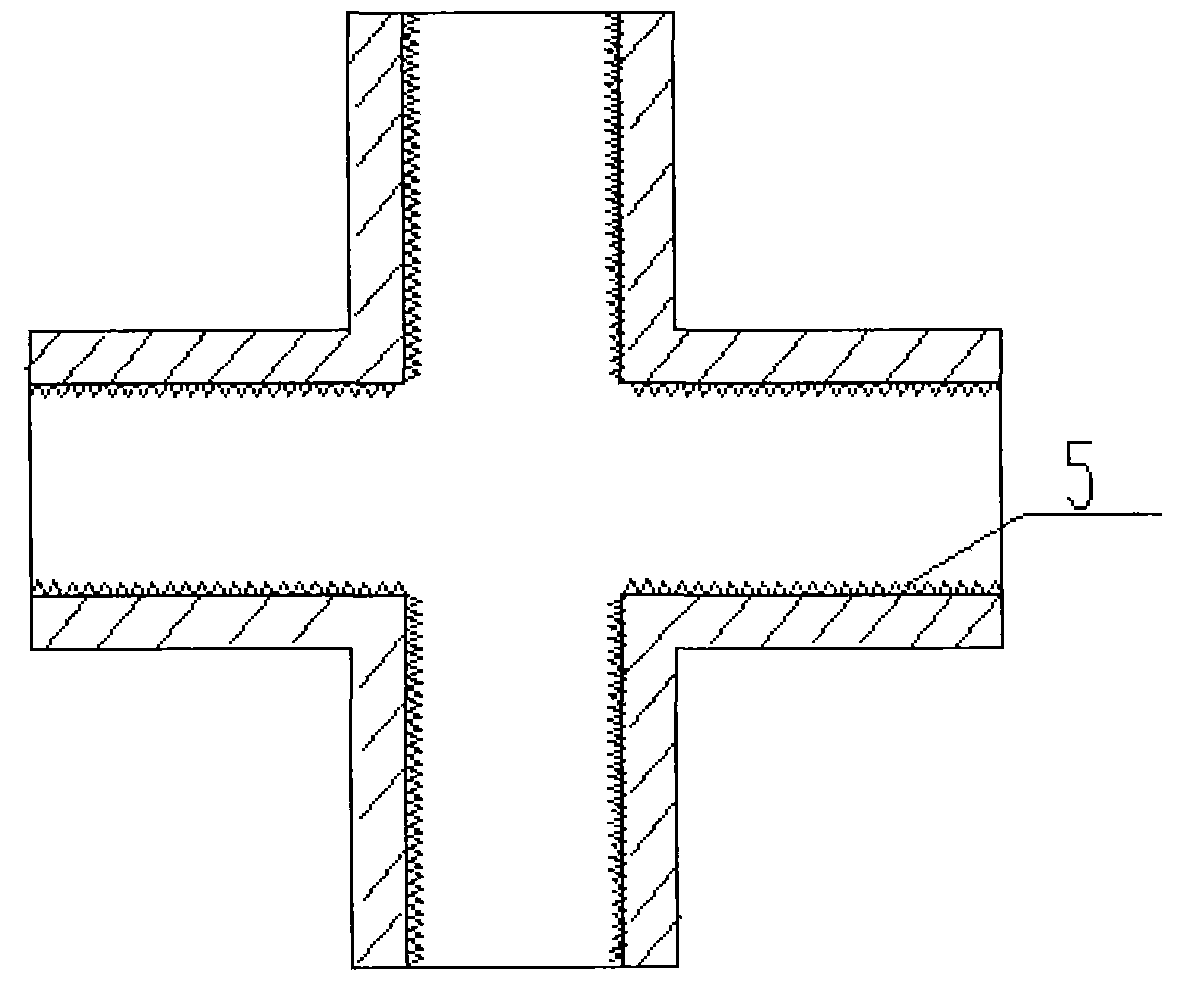

[0009] The steel bars are processed into threads at the ends before construction, and screwed into the cross-shaped steel bar joints in the direction to be connected during construction.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

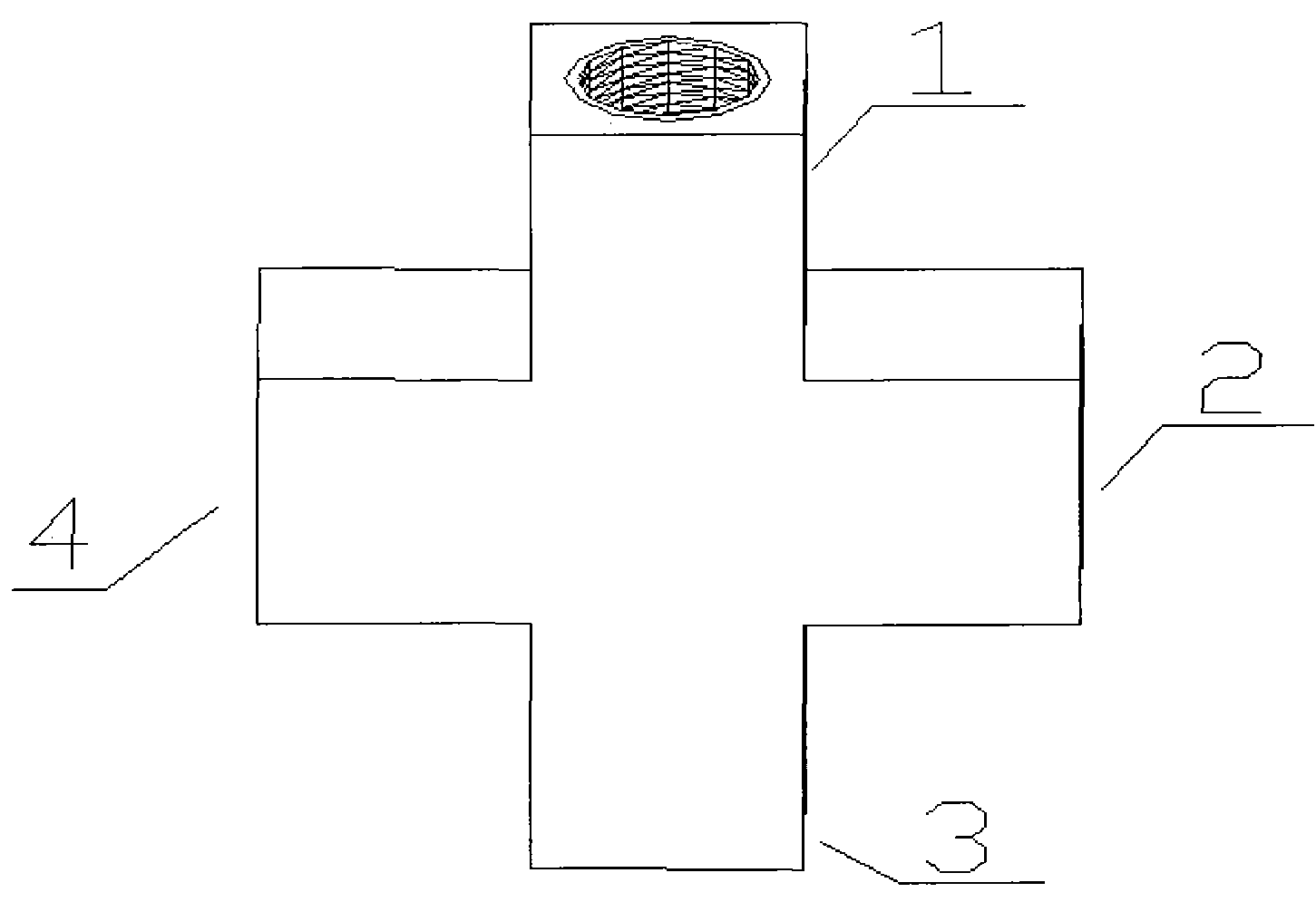

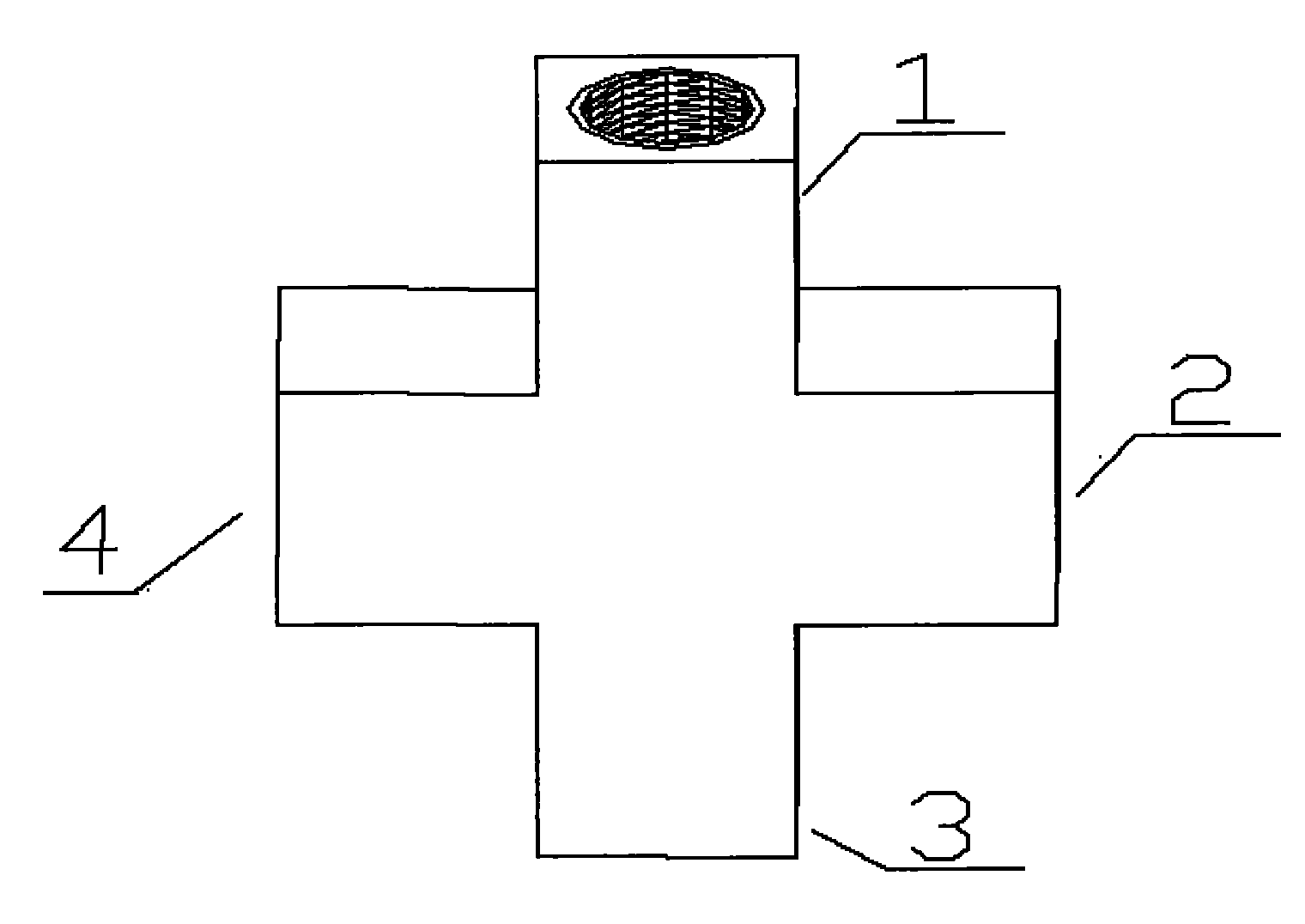

The invention relates to a cruciform reinforcement joint, which is characterized in that: the joint has a cruciform shape, is provided with internal thread sleeves in upper, lower, left and right directions and is used for connecting reinforcements. The joint can connect four reinforcements at most simultaneously and can connect reinforcements in the same direction or vertical direction according to the need. The cruciform reinforcement joint has guaranteed quality, can obviously improve the on-site construction quality and efficiency of reinforcement engineering, and is low in cost and easy and convenient to operate.

Description

technical field [0001] The invention is a steel bar construction technology used in construction engineering, and relates to a joint that can connect up to four steel bars at the same place Background technique [0002] Reinforced concrete structures are widely used in the field of construction engineering. In the on-site construction of reinforced concrete structures, when the steel bars need to be connected to each other, they are usually connected by welding, bundling or threaded connection. However, the construction conditions at the welding site are poor, there are many interference factors, and the work efficiency is low, which easily affects the construction period, and the welding points are brittle and easy to break. And the binding force effect is poor. Although the threaded connection is easy to operate and has a good stress effect, it is only for the connection of steel bars in the same direction, and there is nothing that can be done when there are vertical st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C5/18

Inventor 张鑫犇陆海泉

Owner 张鑫犇

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com