Mechanically-held tile

A technology of mechanical fixing and facing bricks, applied in the direction of floor, covering/lining, construction, etc., can solve the problems of size and design size error, waste of material and space, and the sealing effect is not optimal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] An improved method of manufacturing mechanically secured tiles during injection using preformed parts is disclosed herein.

[0074] In the following description, the manufacturing method of mechanically fixed facing tiles and the like is illustrated as a preferred embodiment, and it will be apparent to those skilled in the art that changes may be made without departing from the scope and spirit of the present invention, including adding and / or or replace. Specific details may be roughly described so as not to obscure the characteristics of the invention; however, the disclosure is written to enable one skilled in the art to implement the teachings herein without undue experimentation.

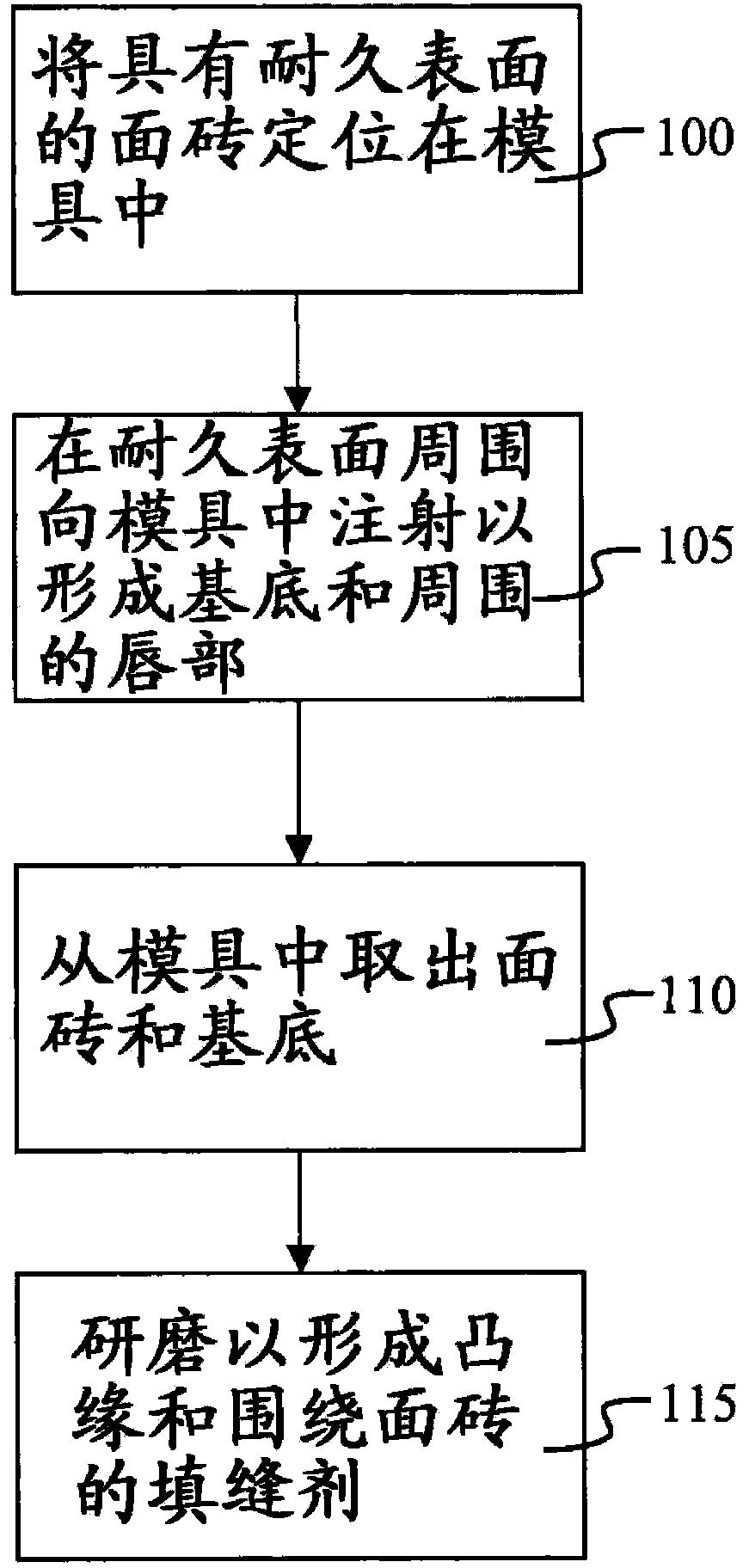

[0075] figure 1 Four steps are shown in the prior art method of making facing tiles with interconnection mechanisms. First, a standard facing tile is positioned in the mold at step 100 with its wear surface flush against one surface of the mold, then, at step 105, a flowable material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com