Corrugated steel pipe haved dual type

A technology for corrugated steel pipes and plastic pipes, applied in the field of corrugated steel pipes, can solve the problems of difficulty in connecting corrugated steel pipes and reduced productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

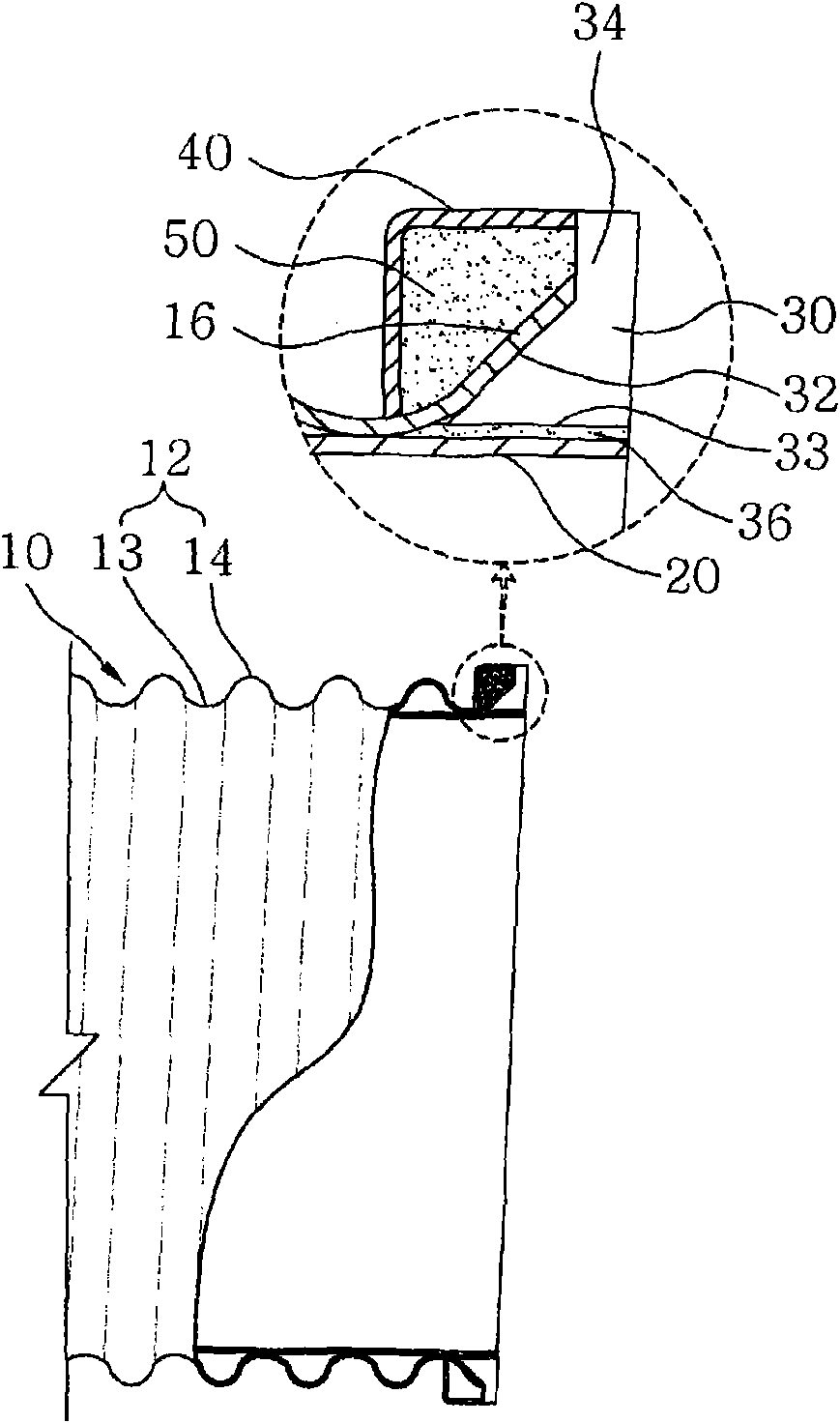

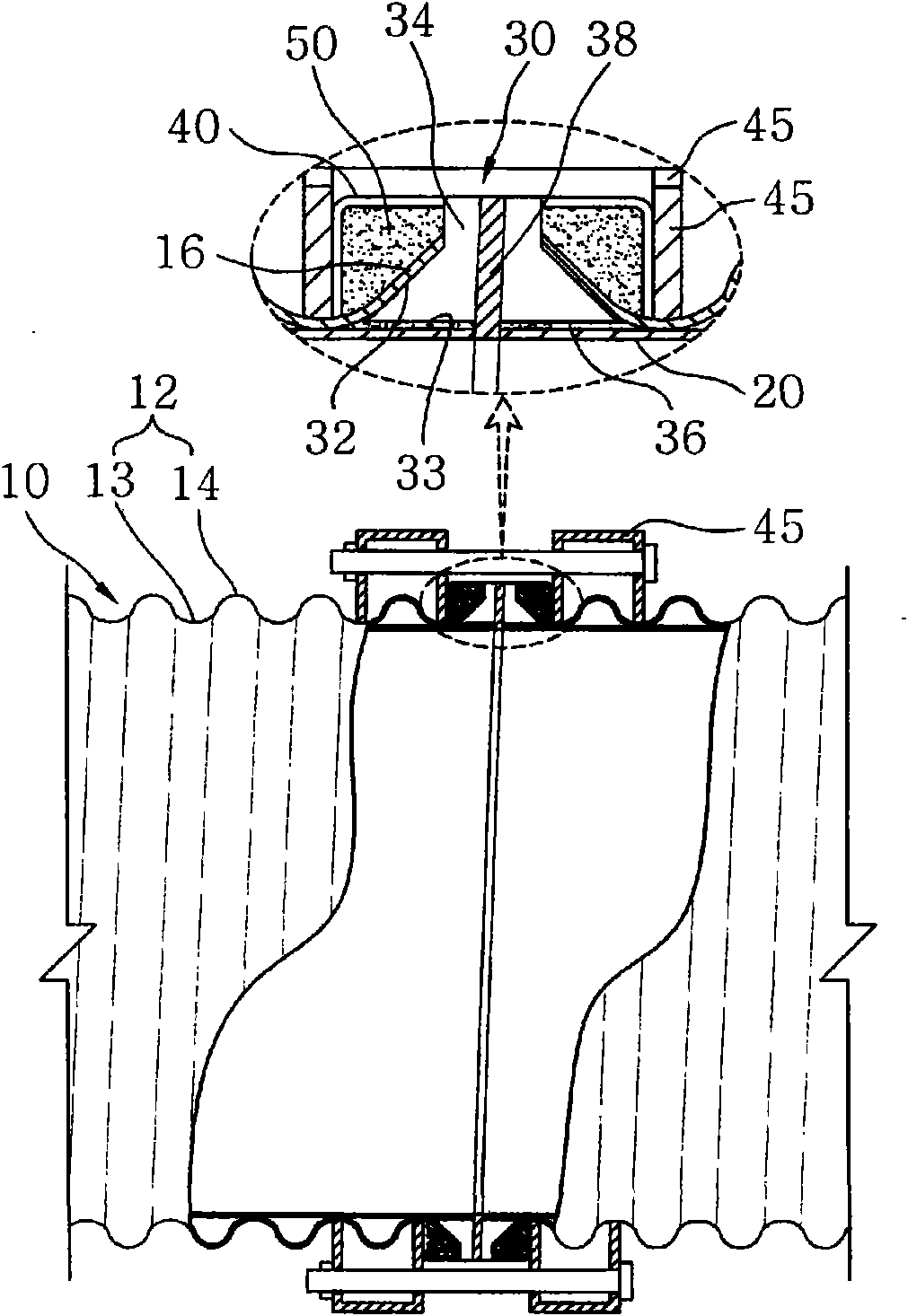

[0016] Hereinafter, a corrugated steel pipe having a double structure according to the present invention will be described with reference to the accompanying drawings.

[0017] figure 1 What is shown is a partially enlarged view of a corrugated steel pipe 10 connected with a smooth-walled plastic pipe according to an embodiment of the present invention. figure 2 Shown is an enlarged partial view of connected corrugated steel pipes 10 according to an embodiment of the present invention.

[0018] refer to figure 1 with figure 2 , a pipe having a double structure of the present invention includes: a corrugated steel pipe 10 having a predetermined length and having an inner peripheral surface formed with a helical protruding portion and an outer peripheral surface formed with a helical protruding portion, A plastic pipe 20 with a smooth wall is inserted into the corrugated steel pipe 10. The outer diameter of the plastic pipe 20 with a smooth wall is equal to the inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com