Bucket wheel excavator

A technology for excavators and bucket wheels, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of waste of manpower and material resources, low degree of mechanization, and unsatisfactory satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

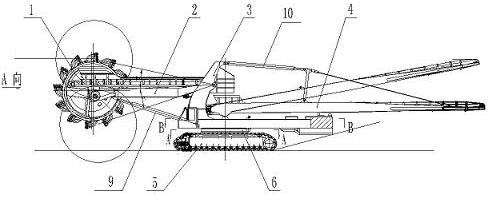

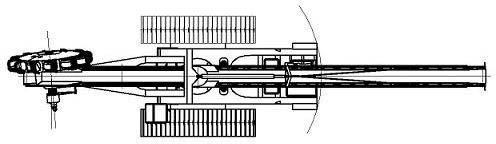

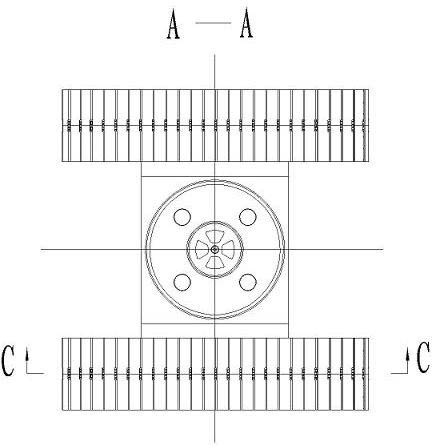

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , as shown in Figure 5 and Figure 6, the bucket wheel excavator includes seven parts: bucket wheel mechanism 1, material receiving arm 2, L beam 3, discharge arm 4, walking mechanism, center large slewing 6 and center small slewing 7. The wheel mechanism 1 is installed on the front end of the material receiving arm 2, the rear end of the material receiving arm 2 is hinged on the upper part of the L beam 3, one end of the discharge arm 4 is supported on the central small swing 7, and the other end is connected to the top of the L beam 3 through a tie rod , the central large slewing 6 is installed between the L beam 3 and the central frame, the central small slewing 7 is installed on the central frame, the bucket wheel mechanism 1 is composed of a hydraulic motor 20, a bucket wheel reducer 21, a bucket wheel shaft 19, and a bucket wheel body 22 and a hopper, the bucket wheel shaft 19 is installed between the two beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com