Vegetable gelatin adhesive for spray seeding and preparation method thereof

A plant and adhesive technology, applied in chemical instruments and methods, applications, fertilizer mixtures, etc., can solve problems such as adverse effects on root growth of subsequent crops, poor bonding strength and performance stability, and non-degradation, and improve soil water retention. and corrosion resistance, good fluidity, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

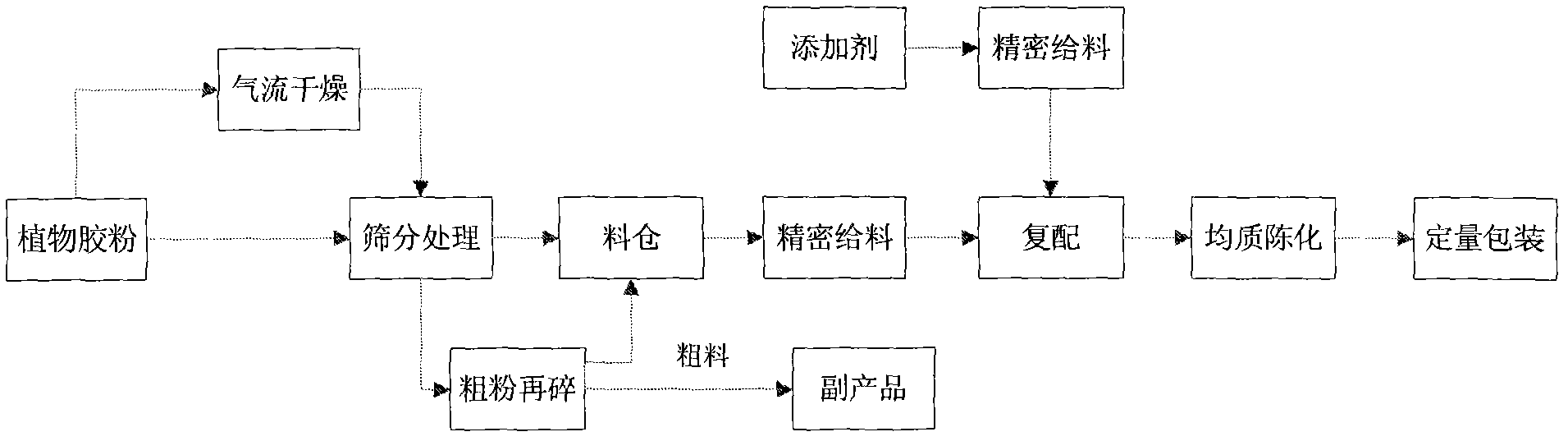

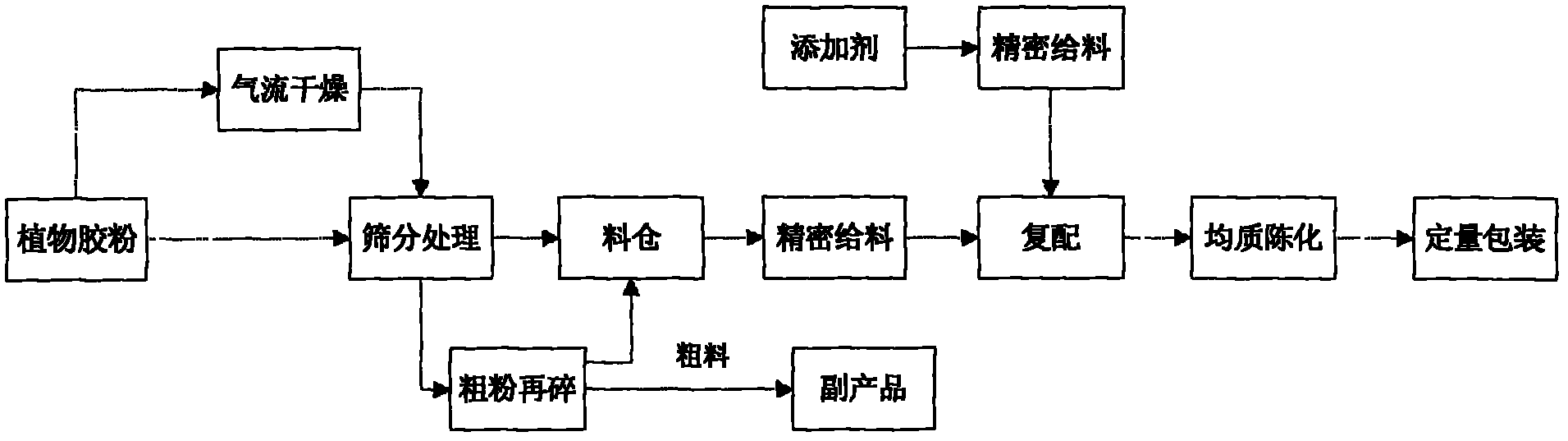

Method used

Image

Examples

Embodiment 1

[0029] The low-viscosity vegetable glue adhesive suitable for spraying on flat ground is prepared from the following raw materials in parts by weight:

[0030] 1. Plant seed gum powder: locust bean gum powder 91.5%

[0031] 2. Initiator: potassium persulfate 1.5%

[0032] 3. Diffusion agent: sodium tripolyphosphate 2%

[0033] 4. Inhibitors: o-hydroxybenzoic acid 2.5%

[0034] 5. Antifoaming agent: polydimethylsiloxane 1%

[0035] 6. Activator: Sodium Carbonate 1.5%

[0036] crafting process:

[0037] 1. Weigh 100 parts of vegetable gum powder that has passed through 160 mesh after sieving and has a moisture content of 10% to 20%, and put it into a mixing tank.

[0038] 2. Weigh 1.6 parts of initiator, 2.2 parts of diffusing agent, 2.7 parts of inhibitor, 1.1 parts of defoamer, and 1.6 parts of activator.

[0039] 3. Turn on the mixer, and the mixing speed is 24~100rpm. First add the diffusing agent and stir for 3 minutes, then add the initiator, auxiliary agent, inhibi...

Embodiment 2

[0045] Medium-viscosity vegetable adhesives suitable for spraying construction on gentle slopes:

[0046] 1. Plant seed powder: Fenugreek powder 91.6%

[0047] 2. Initiator: potassium persulfate 1.2%

[0048] 3. Diffusion agent: sodium phosphate 2.2%

[0049] 4. Inhibitors: o-hydroxybenzoic acid 2.5%

[0050] 5. Antifoaming agent: polydimethylsiloxane 1.0%

[0051] 6. Activator: sodium sulfide 1.5%

[0052] crafting process:

[0053] 1. Weigh 100 parts of vegetable gum powder that has passed through 160 mesh after sieving and has a moisture content of 10% to 20%, and put it into a mixing tank.

[0054] 2. Weigh 1.3 parts of initiator, 2.4 parts of diffusing agent, 2.7 parts of inhibitor, 1.1 parts of defoamer, and 1.6 parts of activator.

[0055]3. Turn on the mixer, and the mixing speed is 24~100rpm. First add the diffusing agent and stir for 3 minutes, then add the initiator, auxiliary agent, inhibitor and defoamer sequentially every 1 minute. The compounding time is...

Embodiment 3

[0061] High-viscosity vegetable glue adhesive suitable for spraying construction on steep slopes,

[0062] 1. Plant seed gelatin powder: 93% kale bean gelatin powder

[0063] 2. Initiator: potassium persulfate 1.0%

[0064] 3. Diffusion agent: sodium tripolyphosphate 2.0%

[0065] 4. Inhibitor: o-hydroxybenzoic acid 2.0%

[0066] 5. Antifoaming agent: polydimethylsiloxane 1.0%

[0067] 6. Activator: Sodium Carbonate 1.0%

[0068] crafting process:

[0069] 1. Weigh 100 parts of vegetable gum powder that has passed through 160 mesh after sieving and has a moisture content of 10% to 20%, and put it into a mixing tank.

[0070] 2. Weigh 1.1 parts of initiator, 2.2 parts of diffusing agent, 2.2 parts of inhibitor, 1.1 parts of defoamer, and 1.1 parts of activator.

[0071] 3. Turn on the mixer, and the mixing speed is 24~100rpm. First add the diffusing agent and stir for 3 minutes, then add the initiator, auxiliary agent, inhibitor and defoamer sequentially every 1 minute. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com