Process for preparing calcium chloride solution by utilizing ammonia soda filtration mother liquor

The technology of a calcium chloride solution and a processing method is applied in the technical field of preparing a calcium chloride solution by filtering a mother liquor with ammonia and alkali, and can solve the problems of high cost, difficulty in raw materials of high-concentration calcium solution, inability to prepare calcium chloride, etc. The effect of saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

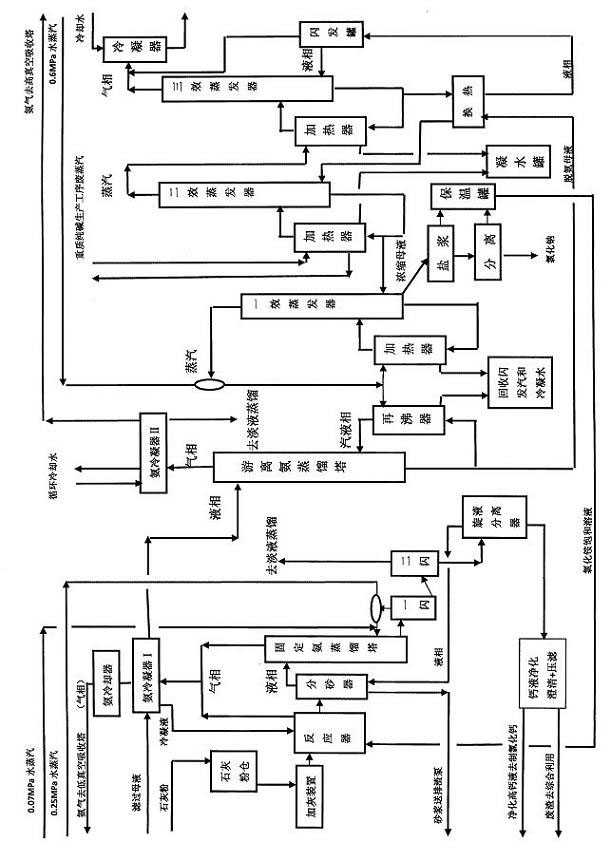

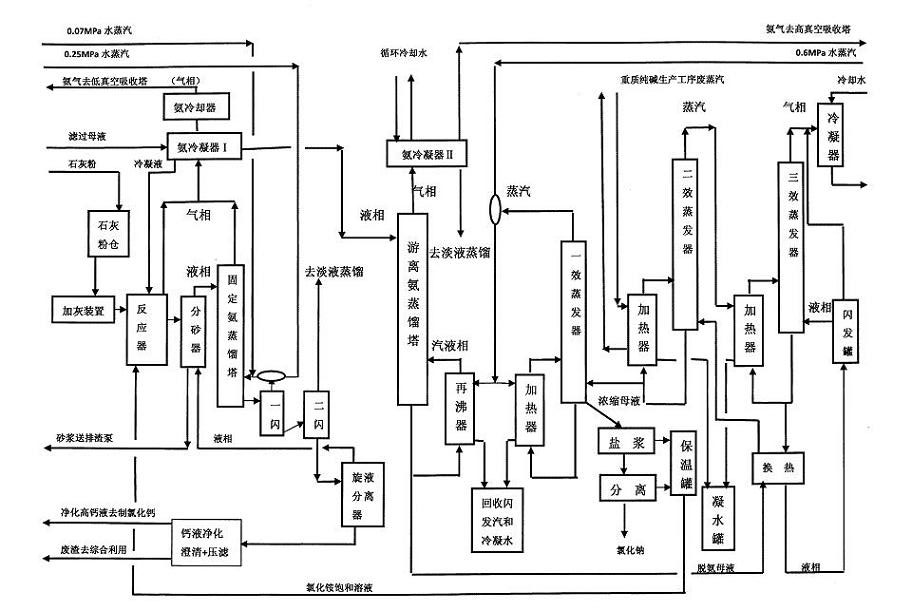

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, the technical method of utilizing ammonia alkali to filter mother liquor to prepare calcium chloride solution described in the present invention is explained in detail.

[0028] The process for preparing calcium chloride solution by filtering mother liquor with ammonia alkali according to the present invention is an improvement to the traditional method of preparing soda ash by using distillation waste liquid to prepare calcium chloride. The alkali making process is the same as the traditional process:

[0029] 1. Refined brine: because the sodium chloride solution used contains C a 2+ , M g 2+ They will generate other insoluble double salts such as calcium carbonate during the ammoniation or carbonation process, which will block equipment and pipelines and affect heat transfer and product quality. Therefore, these impurities must be removed before the brine enters the ammonia absorption tower. Its refining method is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com