Standard complementary metal oxide semiconductor (CMOS) process-based color image sensor

A color image and color technology, applied in the field of metal grating color image sensor and semiconductor CMOS image sensor, can solve the problems that limit the high integration and low cost of semiconductor color image sensor, achieve low cost, high integration, and realize noise elimination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

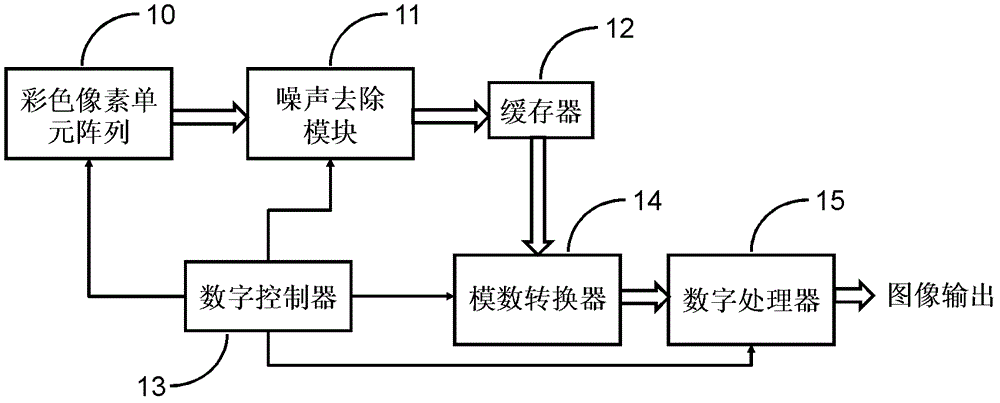

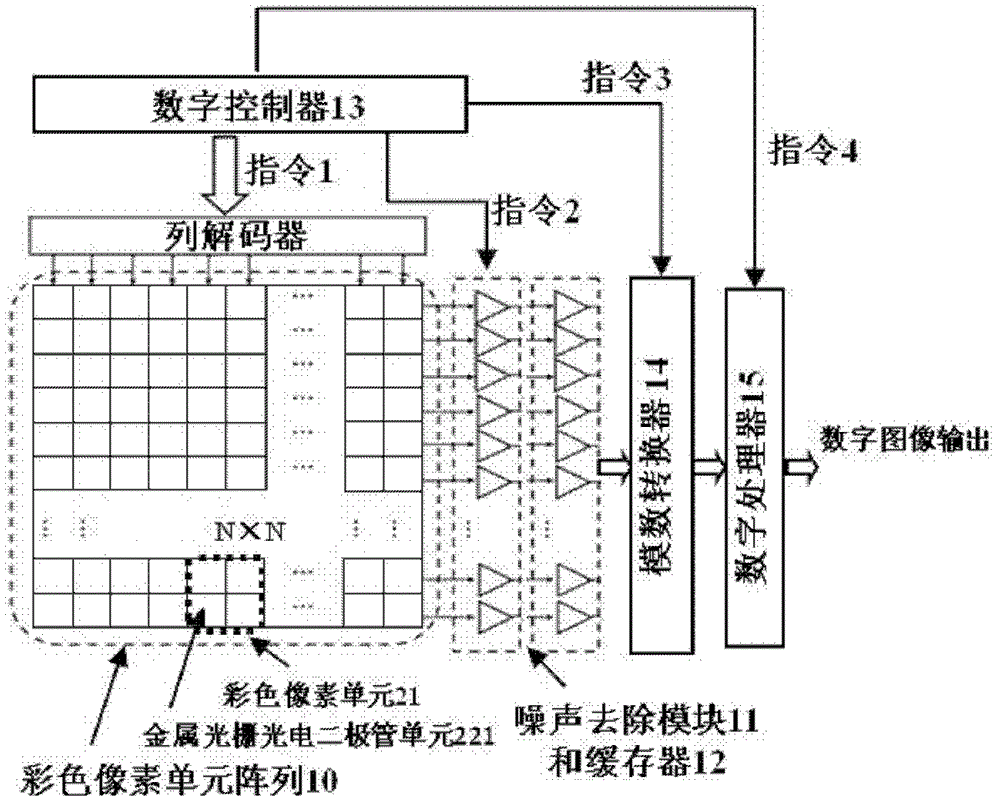

[0028] see figure 1 As shown, the present invention provides a kind of color image sensor based on standard CMOS process, comprising:

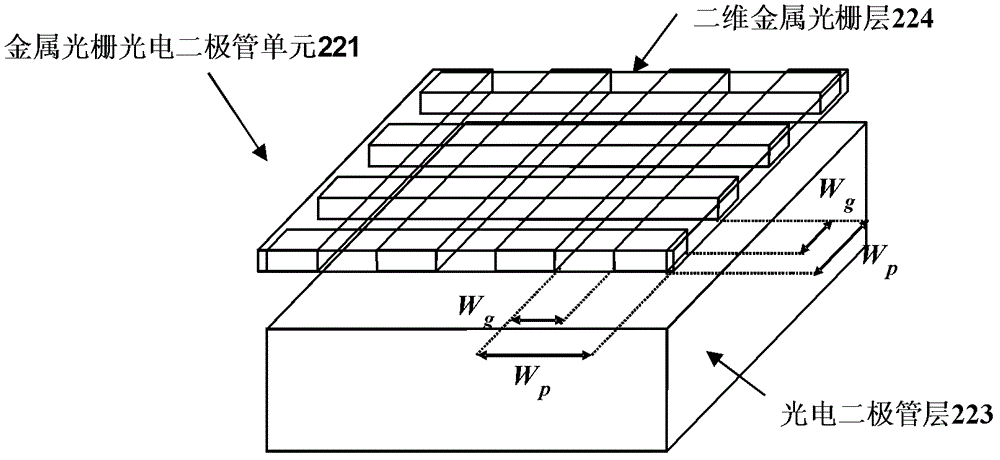

[0029] A color pixel unit array 10 is used to collect the original information of the incident light, and convert the collected color image optical signal into an electrical signal; the color pixel unit array 10 is arranged in a Bayer mosaic pattern, and each color pixel unit 21 It includes four metal grating photodiode units 221, which are one red, two green, and one blue metal grating filter unit. The metal grating photodiode unit 221 consists of a CMOS process photodiode layer 223 and a two-dimensional metal grating layer 224 Composed, the metal grating photodiode unit 221 is directly formed on the photodiode layer 223 by a two-dimensional metal grating layer 224, the two-dimensional metal grating layer 224 is composed of the first metal layer of the standard process used, and the period value of the metal grating is given by The grating i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com