Method for assembling 300 to 1000-core composite superconducting blank

An assembly method and superconducting technology, which are applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve problems such as large numbers, affecting the performance of wires, and irregular rows of mandrels, etc., to achieve Broken cores and core wires are less overlapped, saving wire processing costs, and neatly arranged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

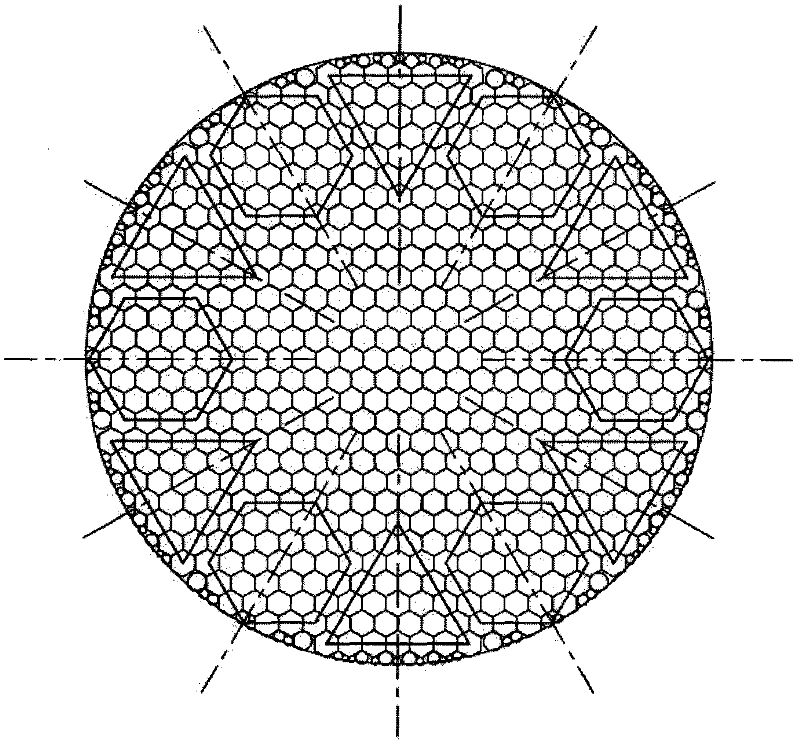

[0025] Example 1: Take the assembly of 528 cores and the final NbTi / Cu composite superconducting blank with a hexagonal mandrel with a size of 6.580mm across the sides as an example, and demonstrate this assembly by comparing the subsequent stretching process and the cross-section of the final strand with the design For the effectiveness of the method, see Figure 4 ,Specific steps are as follows:

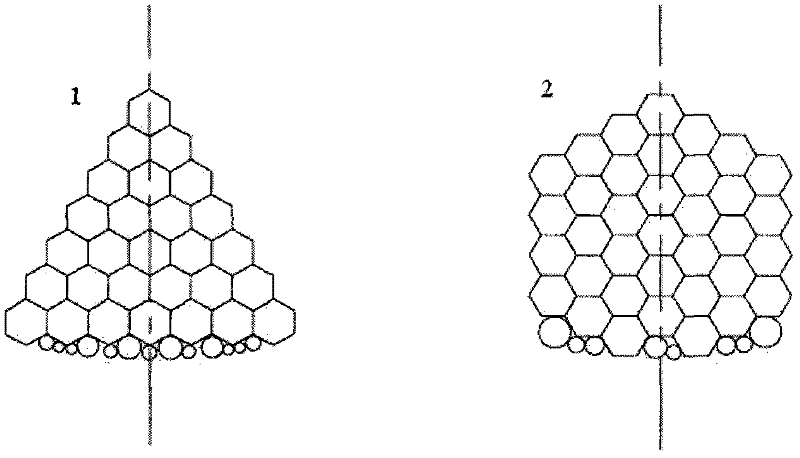

[0026] Step 1: according to the number of hexagonal core rods of the designed superconducting wire section, arrange six regular triangles and regular hexagons evenly along the outer circumference and at mutual intervals; the sides of the regular triangle are the sides of 7 hexagonal core rods, and the sides of the regular hexagon are 4 sides of hexagonal mandrels, see figure 1 ;

[0027] Step 2: Combine the hexagonal mandrel in each equilateral triangle and the copper plunger between it and the circumference to form a triangular small partition, and use copper wire or tie to get ...

Embodiment 2

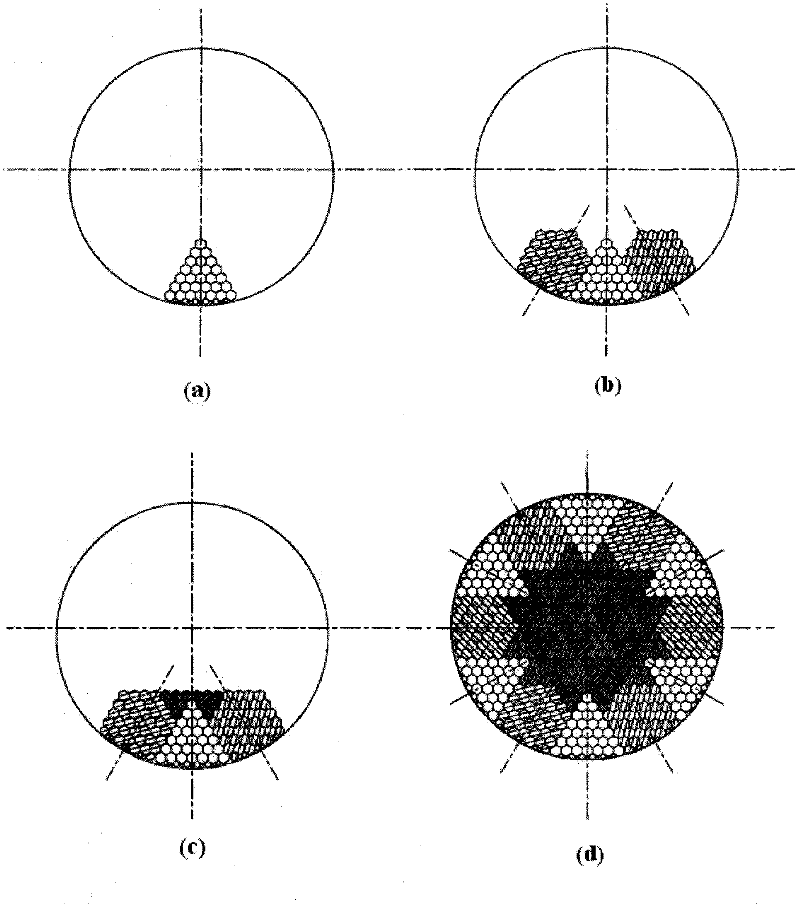

[0035] Embodiment 2: Assembling 917 cores, the hexagonal mandrel with a size of 5.518 mm across the composite blank is assembled, and the specific steps are as follows:

[0036] Step 1: according to the number of hexagonal mandrels of the designed superconducting wire section, arrange six regular triangles and regular hexagons evenly along the outer circumference and at mutual intervals; the side of the regular triangle is the side of 9 hexagonal mandrels, and the side of the regular hexagon is Sides of 5 hexagonal mandrels, see Figure 5 (a);

[0037] Step 2: Combine the hexagonal mandrel in each equilateral triangle and the copper plunger between it and the circumference to form a triangular small partition, and use copper wire or tie to get six regular triangular small partitions, see Figure 5 (b); the hexagonal mandrel in each regular hexagon and the copper insert rod between the circumference form a regular hexagonal small partition, and use copper wire or tie to get si...

Embodiment 3

[0045] Embodiment 3: Assembling 305 cores of NbTi / Cu composite superconducting final billet assembly, the size of the opposite side of the mandrel is 9.546mm, the specific steps are as follows:

[0046] Step 1: According to the number of hexagonal core rods of the designed superconducting wire section, arrange six regular triangles and regular hexagons evenly along the outer circumference and at mutual intervals; the sides of the regular triangle are the sides of 5 hexagonal core rods, and the sides of the regular hexagon are Sides of 3 hexagonal mandrels, see Image 6 (a);

[0047] Step 2: Combine the hexagonal mandrel in each equilateral triangle and the copper plunger between it and the circumference to form a triangular small partition, and use copper wire or tie to get six regular triangular small partitions, see Image 6 (b); the hexagonal mandrel in each regular hexagon and the copper insert rod between the circumference form a regular hexagonal small partition, and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com