Novel energy-saving stove of gas having a flat top side

A gas stove, a brand-new technology, applied in the direction of stove/stove top, burner, combustion method, etc., can solve the problems of inconsistency in plane visual effects, lack of beautification of the kitchen, etc., to improve heating efficiency and ensure full combustion , Improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach 200

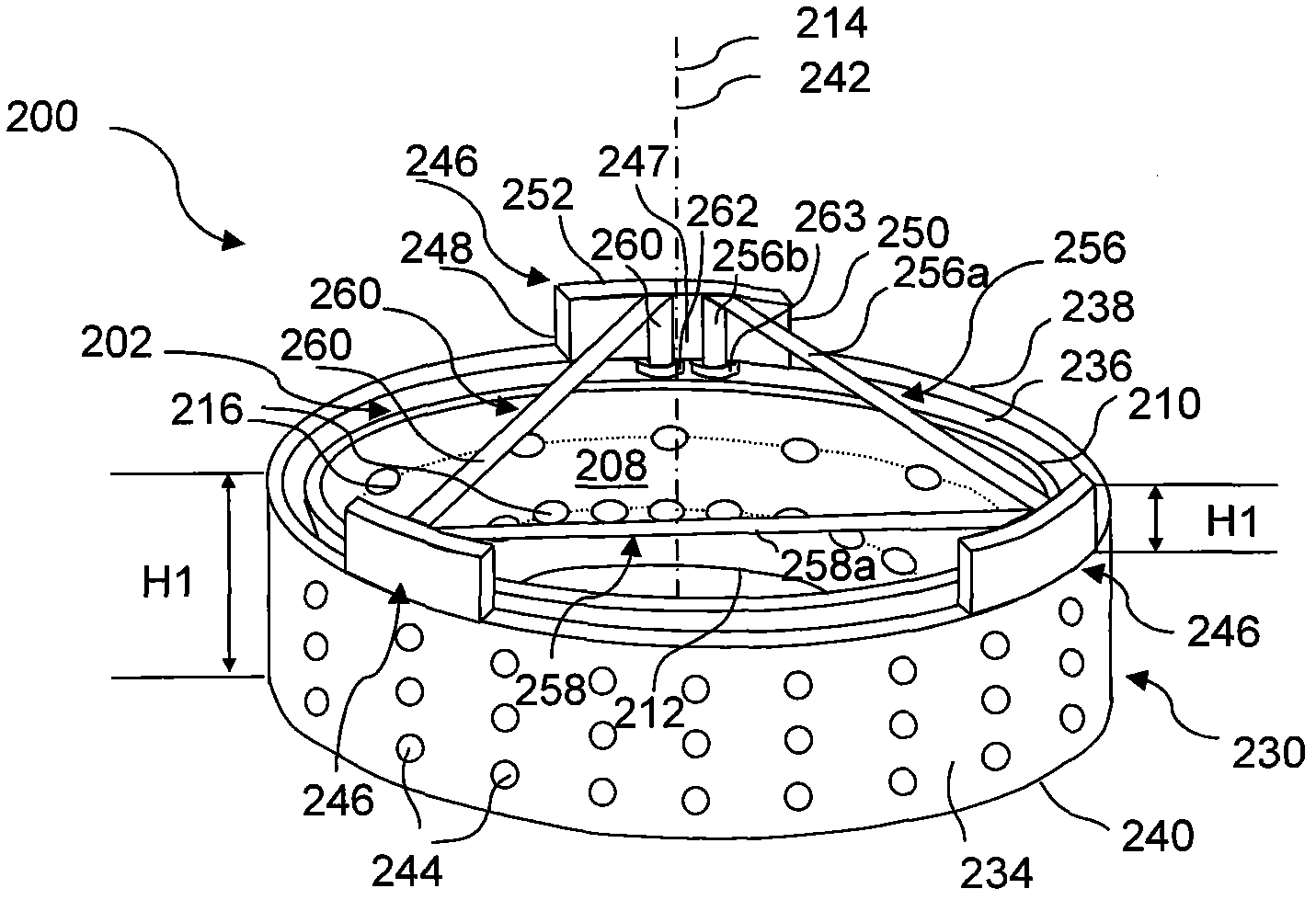

[0134] Figure 4 A second embodiment 200 of the invention is described comprising a hollow annular concave inner disk 202 and a cylindrical periphery 230 .

[0135] It can be confirmed that the inner tray 202 is exactly the same as the inner tray 102 in the first embodiment, so every structure of the inner tray 202 will not be described again. The structure of inner disk 202 is in Figure 4 is represented by a number with 3 digits. For a structure of the inner disc 202 because it is the same as the same structure in the inner disc 102 , the numbers of the first and second digits among the numbers marking the structure are the same as the numbers in the inner disc 102 . The difference is that the third digit is replaced with 200 instead of 100 in the inner disk 102 .

[0136]As shown, the cylindrical periphery 230 has a height "H12" and has an outer cylinder 234 or outer surface, an inner cylinder 236 or inner surface, a top edge 238 of a top circumferential opening, and a b...

example (I

[0147] Disclosed below are examples of the application of the device for controlling flame heat transfer of the present invention on a burner. This example is provided only to verify the above statement that the present invention can improve heating efficiency, but not to limit the present invention. However, in order to reduce space, the following disclosure only describes the results of examples. Details regarding examples can be found in US Patent Application No. 12 / 313,940.

[0148] Table 1: Results of tests on experimental and control samples

[0149] test

sample

cooking utensils

time (minutes)

time difference (minutes)

is the % of the control sample

Increased Efficiency %

1

experiment

teapot

18.75

-4.50

81.44

+18.56

2

control

teapot

24.25

[0150] 3

control

aluminum pan

24.67

4

experiment

aluminum pan

21.0...

example (II

[0174] Disclosed below are examples of the application of the present invention to a gas furnace burner. This example is provided only to verify the above statement that the present invention can improve heating efficiency, but not to limit the present invention. However, in order to reduce space, the following disclosure only describes the results of examples. Details regarding examples can be found in US Patent Application No. 12 / 313,940.

[0175] Table 2: Test results for the experimental sample (I-Cap) and the control sample (C-Cap)

[0176] test

sample

cooking utensils

time (minutes)

time difference (minutes)

% of control sample

Increase efficiency%

1

C-Cap

teapot

10.38

2

C-Cap

teapot

10.50

3

I-Cap

teapot

9.38

-1.14

89.09

10.91

[0177] The experimental results listed in Table 2 demonstrate that the use of the inner pan of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com