Magnetorheological intelligent drilling vibration damper

A magneto-rheological and shock absorber technology, which is applied to drilling equipment, drill pipes, drill pipes, etc., can solve the problems of increasing drill string vibration and reducing the efficiency of shock absorbers, and achieves real-time and precise control, a wide range of changes, and effective Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

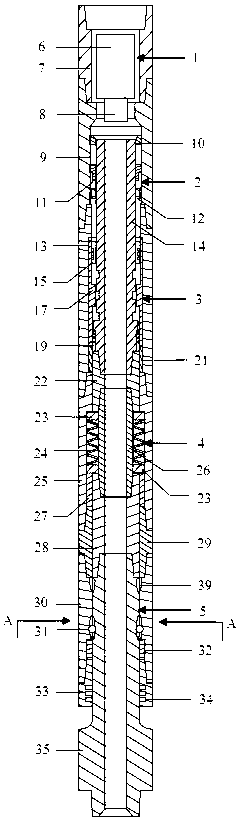

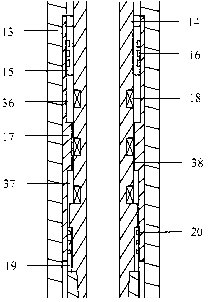

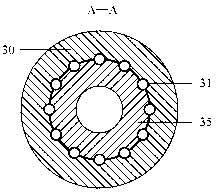

[0014] according to figure 1 As shown, a magnetorheological intelligent drilling shock absorber of the present invention is composed of a turbine generator module 1, a sensor controller module 2, a magnetorheological valve 3, a spring set 4 and a torsion bearing 5; the turbine generator Module 1, sensor controller module 2, magneto-rheological valve 3, spring group 4 and torsion bearing 5 are connected in sequence; the turbine generator module 1 is composed of a turbine generator 6, a turbine generator protection casing 7 and a centralizing joint 8; Sensing controller module 2 is made of sensing controller module shell 9, end support 10, upper sliding bearing 11 and sensing controller 12; Sensing controller 12 is arranged inside sensing controller module 2; Sensing controller The upper end and the lower end of the module shell 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com