Method for synthesizing micron-nano-sized cuprous oxide micropowder by controlling shape of micron-nano-sized cuprous oxide micropowder

A technology of cuprous oxide and a synthesis method, applied in the field of micro-nano materials, can solve the problems of low concentration, uneconomical industrial application, etc., and achieve the effects of low reaction temperature, convenience for large-scale synthesis, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

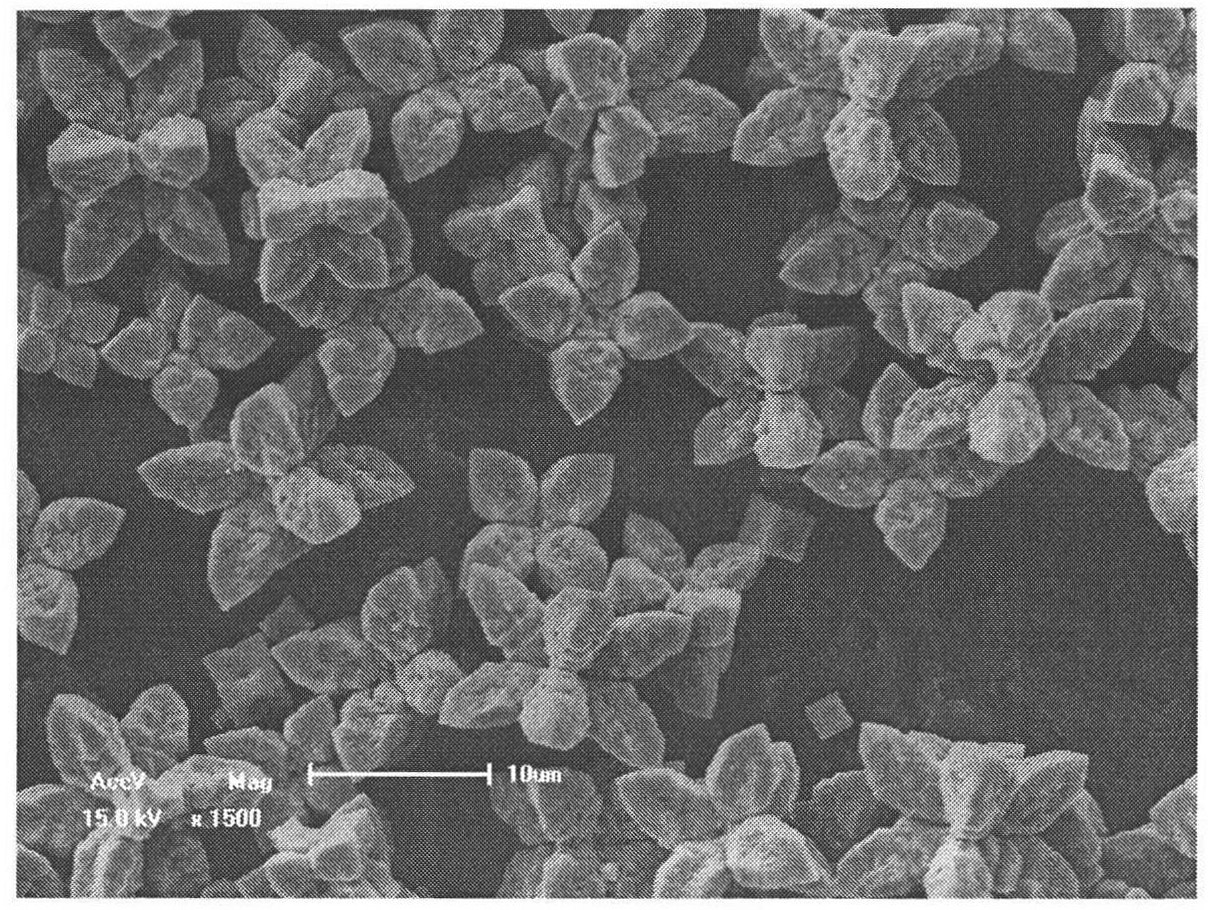

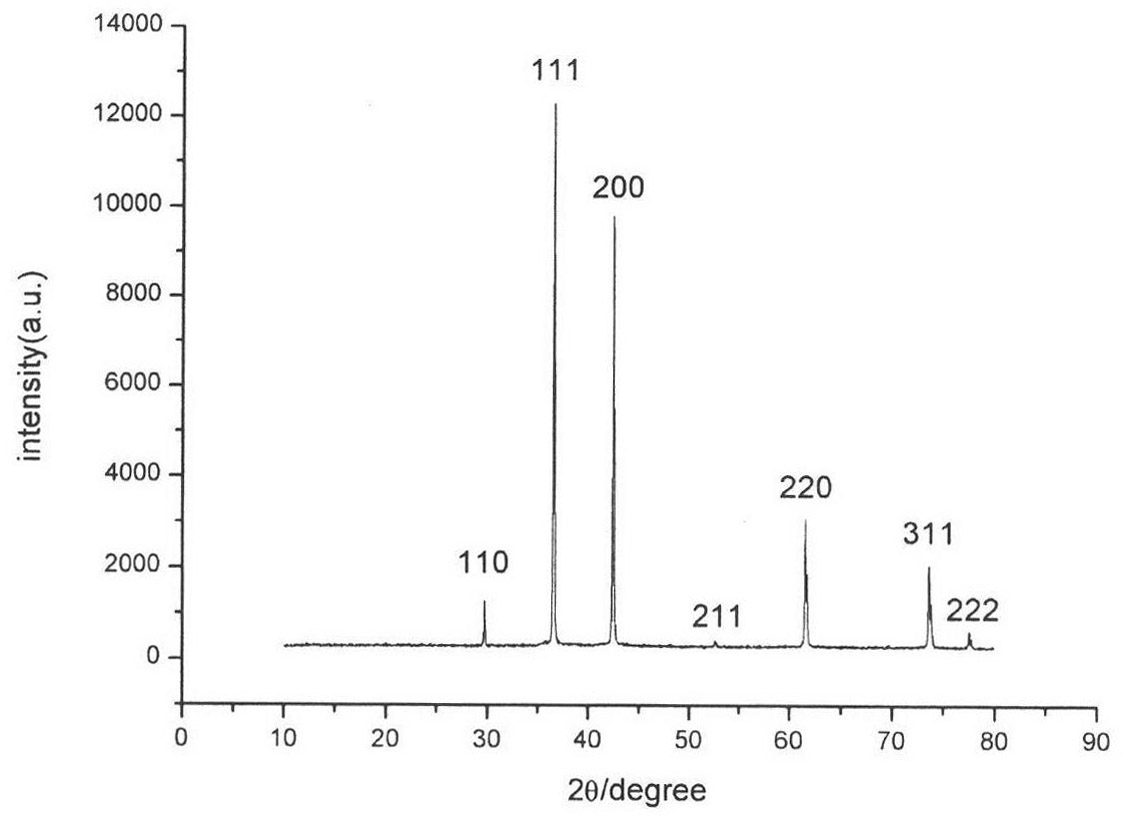

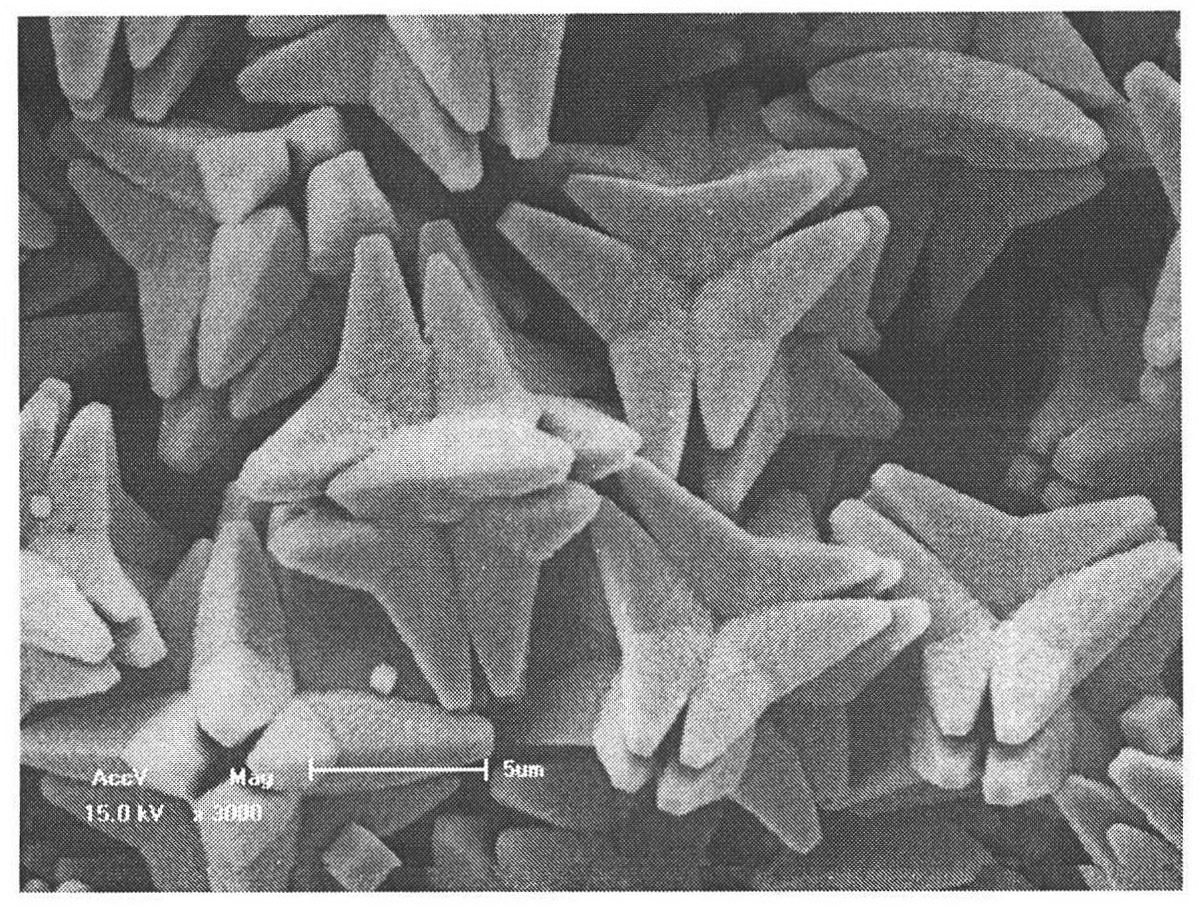

[0025] Get 10g copper sulfate pentahydrate (CuSO 4 ·5H 2 O, A) Place in a 500ml reaction kettle, then add 100ml of distilled water (B), and mechanically stir at 70°C (C) until the copper sulfate pentahydrate is completely dissolved. Then the NaOH solution obtained by dissolving 4.3g of sodium hydroxide (NaOH, D) in 100ml of distilled water (E) was completely poured into the reaction kettle, and the reaction was vigorously stirred at 70° C. (F) for 1 hour (G). Then add 100ml (H) of 0.2mol / L (K) glucose (C6H12O6) solution into the reaction kettle at a rate of 2ml / min (M). After adding it completely, continue to stir and react for 20 minutes (N). The resulting precipitate was filtered, washed three times with distilled water and once with ethanol, and dried in a vacuum oven at 50° C. to obtain powder of cuprous oxide particles. Its morphology was observed by SEM (attached figure 1 ), whose shape is eight-vertex star cuprous oxide, well dispersed. attached figure 2 is the XR...

Embodiment 2 8

[0027] Carry out operation according to embodiment one, wherein usage amount, time and temperature reaction parameter are carried out as follows. The XRD analysis results are all cubic cuprous oxide.

[0028]

[0029] Note: OS: octagonal star; SP: square porous; S1: diamond star; S2: decahedron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com