Structure for reducing equivalent unsprung mass of single cross arm suspension wheel-side electric driving system and method

A technology of electric drive system and wishbone, applied in suspension, elastic suspension, auxiliary drive, etc., can solve problems such as deviation and different deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

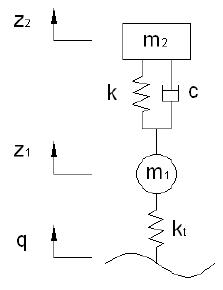

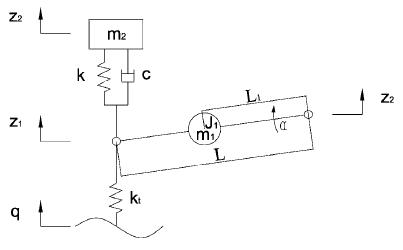

Method used

Image

Examples

Embodiment Construction

[0054] Please refer to the accompanying drawings for a further description of the present invention.

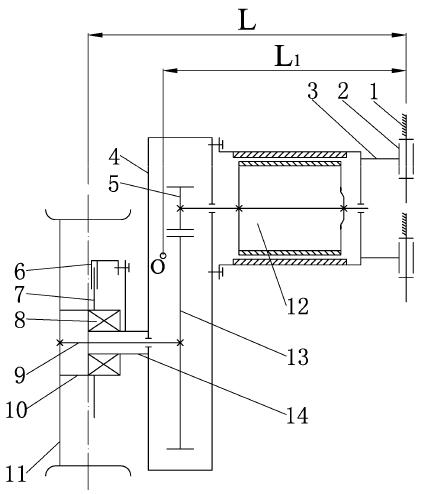

[0055] Such as figure 1 As shown, the present invention provides a structure for reducing the equivalent unsprung mass of the single-wishbone suspension wheel-side electric drive system. The single-wishbone suspension wheel-side electric drive system includes a vehicle frame 1, an elastic rubber hinge 2, Single wishbone suspension swing arm 3, reduction box 4, pinion 5, brake caliper 6, brake disc 7, hub bearing 8, half shaft 9, hub 10, rim 11, motor 12, large gear 13, half shaft Shaft sleeve 14, wherein elastic rubber hinge 2, single wishbone suspension swing arm 3, reduction box body 4, half shaft sleeve 14 and motor 12 are fixedly installed together, wheel hub 10, rim 11, wheel hub bearing 8, half shaft 9. The half shaft sleeve 14 and the brake disc 7 are parts concentric with the wheel, and the reduction box 4, the pinion 5, the brake caliper 6, the motor 12 and the bull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com