Construction method of consolidating horizontal directional drilling hole by grouting coal seam baseboard

A coal seam floor and grouting reinforcement technology, which is applied in directional drilling, earthwork drilling, surveying, etc., can solve the problems of large amount of drilling construction, high construction cost, and low utilization rate of drilling holes, and shorten the time of excavation replacement. time, the effect of grouting reinforcement is enhanced, and the effect of advanced reinforcement is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

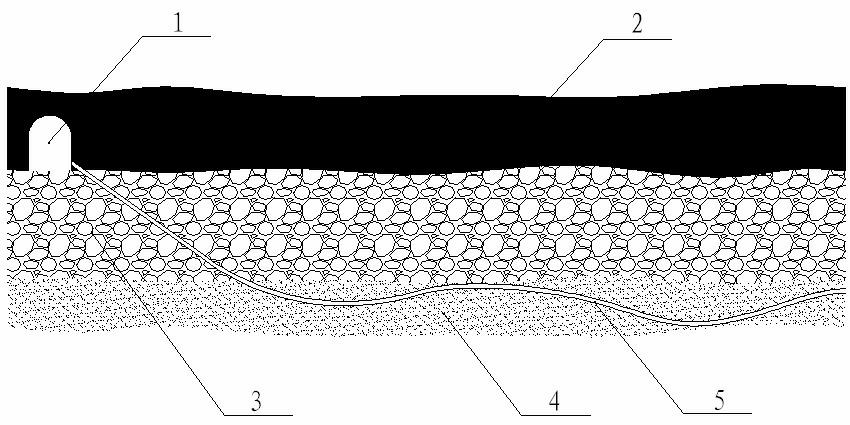

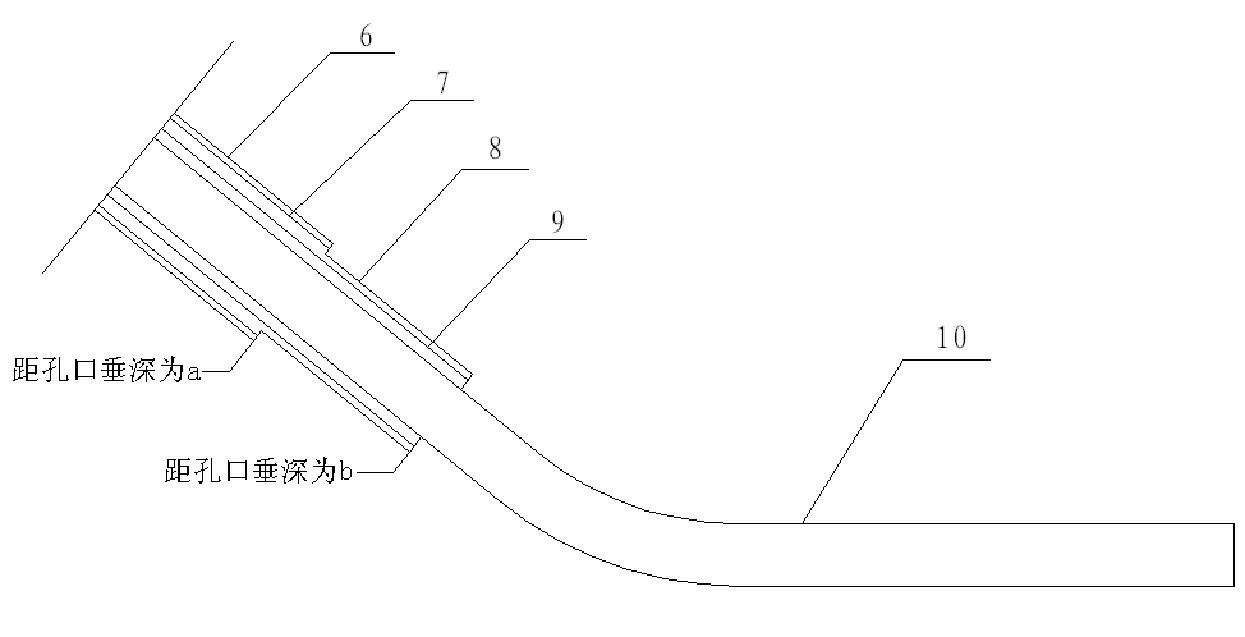

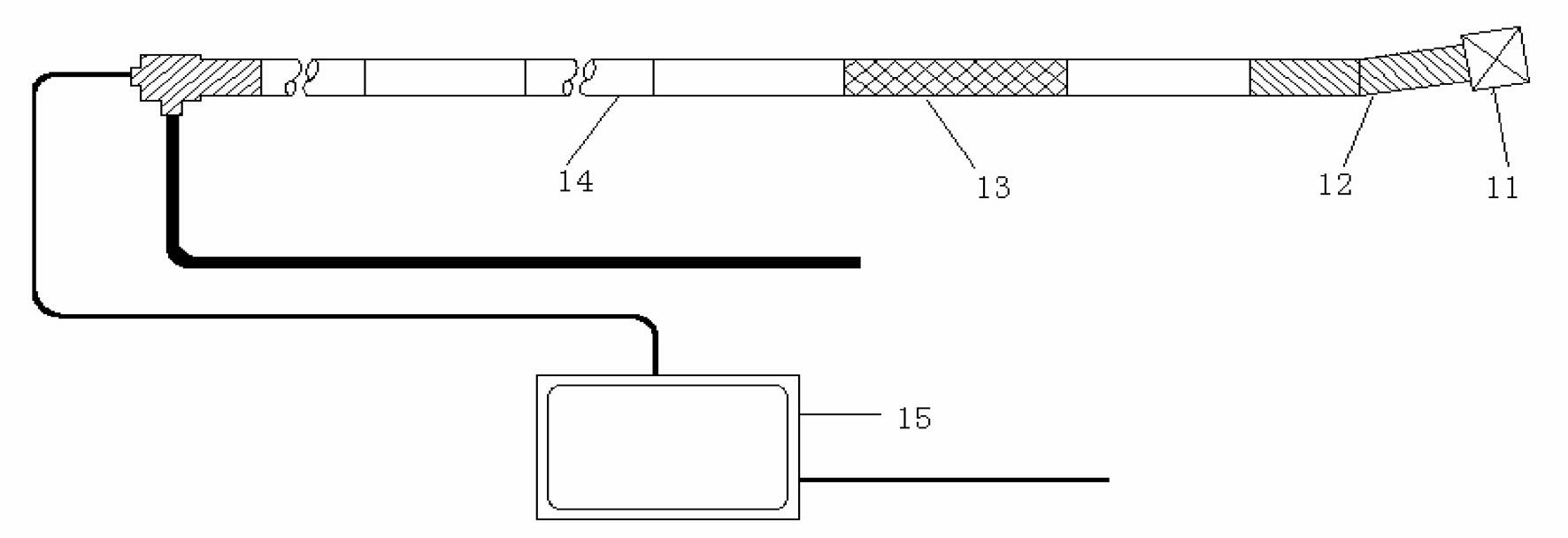

[0031] After a detailed understanding of the geological data of the pre-reinforced stratum, the drilling design is carried out according to the water barrier, the depth of the aquifer and the consolidation range of the working face, and then the drilling construction is carried out. The construction steps and structure of the drilling are as follows: attached figure 1 , 2 As shown, the specific construction steps are as follows:

[0032] (1) Develop the drilling site 1 in the coal seam 2 roadway of the working face, and open a hole in the coal seam 2, and the opening direction points to the coal seam floor water-resisting layer 3 and the aquifer 4; after the drill hole is drilled to a certain depth below the coal seam floor Lift the drill, ream the hole, and install the first-level sealing casing to grout and seal the hole, and sweep the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com