Construction method of sandy soil geological cut-off wall

A construction method and technology of anti-seepage wall, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of low construction efficiency and poor construction quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

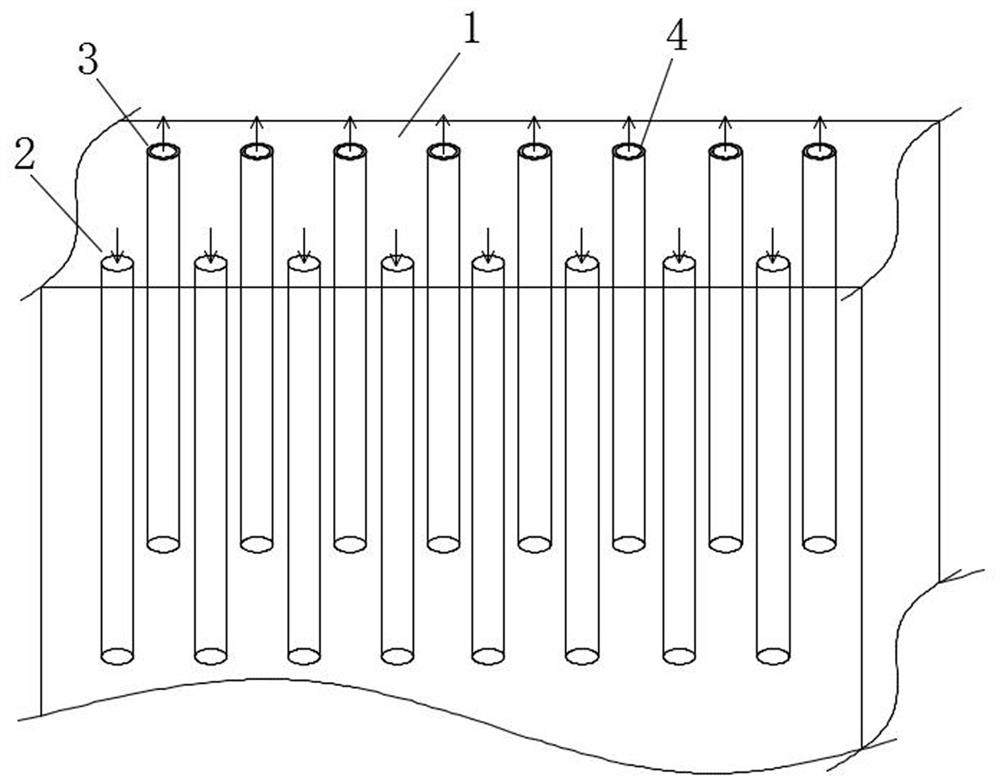

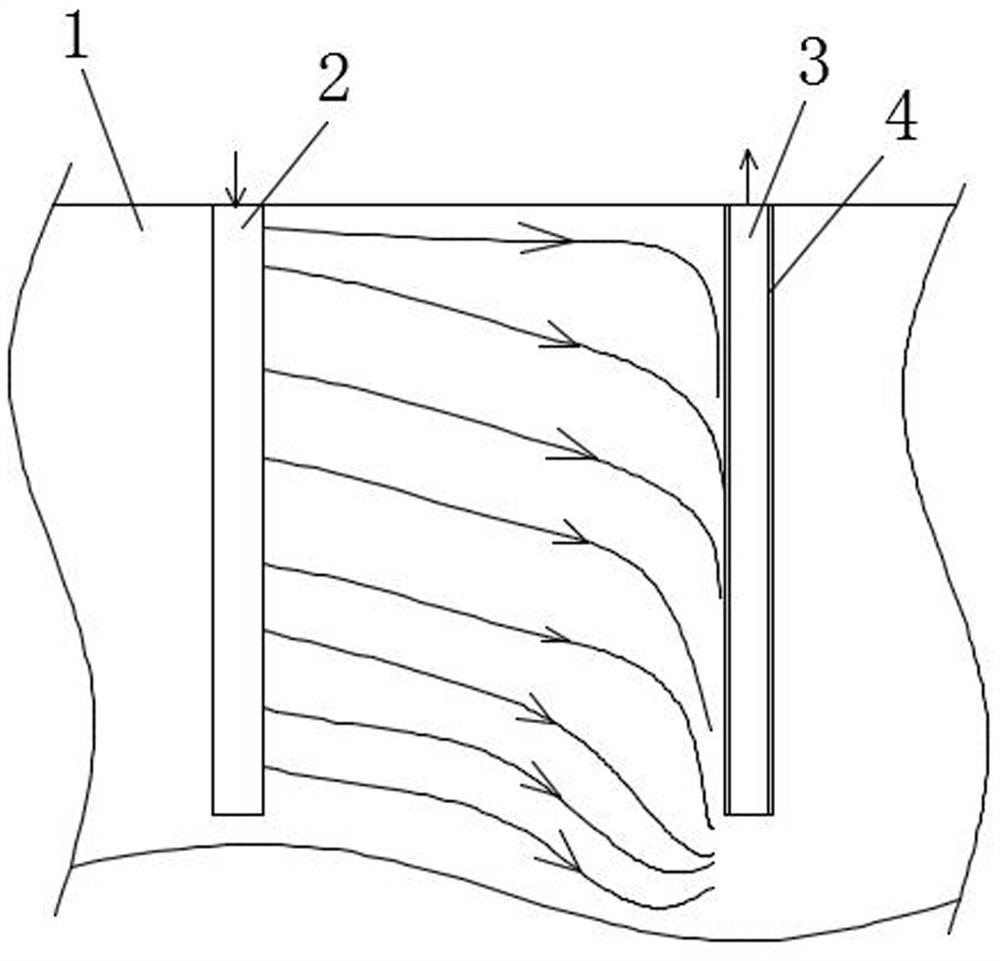

[0034] Such as figure 1 with 2 Shown, a kind of construction method of sandy ground anti-seepage wall, comprises the following steps:

[0035] 1) Along the length direction of the planned cut-off wall, draw the width boundary of the cut-off wall on the sandy soil layer 1, thus forming two parallel preset lines;

[0036] 2) Drill holes symmetrically on two parallel preset lines to form a row of grouting holes 2 and a row of negative pressure holes 3. The depth of the grouting holes 2 and negative pressure holes 3 is equal to the The height of the seepage wall, the distance between the two is the width of the cut-off wall, and each grouting hole 2 and a negative pressure hole 3 are correspondingly distributed along the center of the cut-off wall width, forming a grouting hole group;

[0037] 3) Insert a PC tube 4 with both ends open in each negative pressure hole 3, and the outer wall of the PC tube 4 has the same diameter as the inner wall of the negative pressure hole 3;

...

Embodiment 2

[0047] This example is an improvement made on the basis of Example 1. Its main body is the same as Example 1. The improvement is that the diameters of the grouting hole 2) and the negative pressure hole 3) are both 0.1m , the spacing between two adjacent grouting holes 2) or two adjacent negative pressure holes 3) is 0.5m, and in any group of grouting holes, the spacing between grouting holes 2) and negative pressure holes 3) is 0.8m.

Embodiment 3

[0049] This embodiment is another improvement made on the basis of embodiment 1. Its main body is the same as that of embodiment 1. The improvement is that in step 9), after the grouting construction of the entire anti-seepage wall is completed, Carry out hole-repairing grouting again, the operation of described hole-repairing grouting is: the operation of described hole-repairing grouting is: after construction finishes seven days, first measure the wall-forming quality of anti-seepage wall with the georadar of non-destructive testing, for For areas where the strength does not meet the set requirements, repeat the grouting construction process of steps 5)-8) and test again after seven days until it meets the requirements; for areas where the strength meets the set requirements, pour grouting holes 2 and negative pressure holes 3 and PC pipe 4 are filled and sealed with cement slurry to prevent sundries and rainwater from washing out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com