A kind of preparation method of monodisperse solidified micelle particle

A monodisperse, particle-based technology, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve problems such as limiting the development of colloidal crystals and lack of intermediate dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Wash the styrene monomer with 10% sodium hydroxide solution, remove the polymerization inhibitor, and then use deionized water to wash off the excess alkali solution. After the solution is neutralized with pH test paper, add anhydrous sodium sulfate. Set to dry for 5h;

[0020] 2. Under the heating conditions of 20torr and 40°C, the dried styrene monomer is subjected to vacuum distillation, and the purified styrene monomer is stored in a dark box at 10°C for subsequent use;

[0021] 3. Weigh 0.04g of behenyltrimethylammonium bromide (C 22 TABr), 0.07g cetyltrimethylammonium bromide (C 16 TABr), 0.08g styrene in 1mL ethanol solution, under the condition of constant temperature stirring at 30 ℃, 150μL deionized water was added dropwise to the solution with Langer TJ-1A micro-injection pump, the dripping speed was set to 20μL / min, wait for After the solution is fully dissolved, continue stirring at constant temperature for 2h;

[0022] 4. Under the condition of const...

Embodiment 2

[0026] 1. The treatment method of styrene monomer is the same as above;

[0027] 2. Weigh 0.04gC 22 TABr, 0.07gC 16 TABr, 0.06g styrene in 1mLEtOH solution, under the condition of constant temperature stirring at 30 ℃, 150μL deionized water was added dropwise to the solution with Langer TJ-1A microsyringe pump, the dripping speed was set to 20μL / min, and the solution was fully After dissolving, continue stirring at constant temperature for 2h;

[0028] 3. Under the condition of constant temperature stirring at 30°C, continue to add water dropwise until the mass fraction of deionized water in the total solvent is 85wt%. After the dripping is completed, put the prepared solution into a 70°C oven to preheat for 1 hour;

[0029] 4. Under the protection of nitrogen atmosphere, add K of 1% by mass of styrene monomer to the preheated solution. 2 S 2 O 4 , the polymerization of styrene monomer was initiated under heating at 70 °C, and the reaction was stopped after 2 h.

[0030]...

Embodiment 3

[0032] 1. The treatment method of styrene monomer is the same as above;

[0033] 2. Weigh 0.04gC 22 TABr, 0.07gC 16 TABr and 0.04g styrene in 1mLEtOH solution, under the condition of constant temperature stirring at 30℃, 150μL deionized water was added dropwise to the solution with Langer TJ-1A micro-injection pump, and the dripping speed was set to 20μL / min. After dissolving, continue stirring at constant temperature for 2h;

[0034] 3. Under the condition of constant temperature stirring at 30 °C, continue to add water dropwise until the mass fraction of deionized water in the total solvent is 90 wt%. After the dripping is completed, put the prepared solution into a 70 °C oven to preheat for 1 hour;

[0035] 4. Under the protection of nitrogen atmosphere, add K of 1% by mass of styrene monomer to the preheated solution. 2 S 2 O 4 , the polymerization of styrene monomer was initiated under heating at 70 °C, and the reaction was stopped after 2 h.

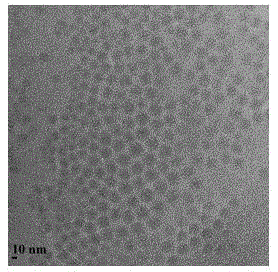

[0036] The size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com