No-fill vibro-shock test device and test method for simulating in-situ stress state sandy soil

A technology of in-situ stress and test methods, applied in the direction of measuring devices, adopting mechanical devices, analyzing materials, etc., can solve the problems that cannot meet the actual requirements, and achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

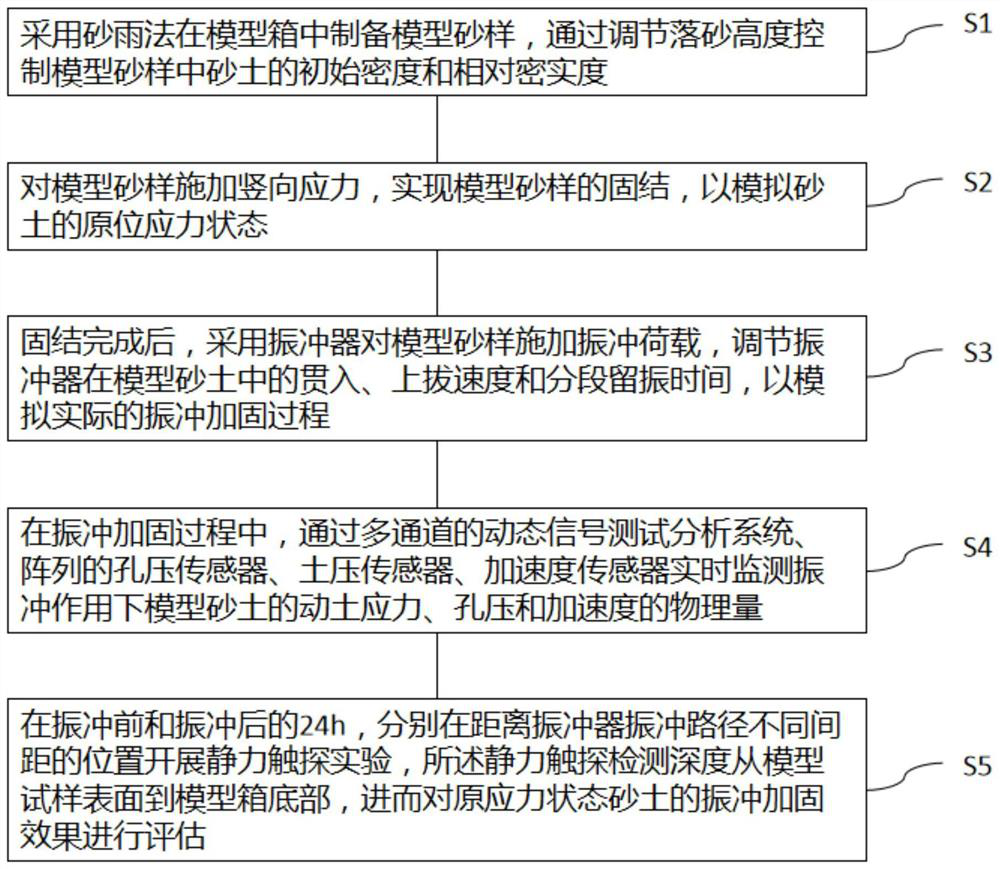

[0051] refer to figure 1 As shown, a non-filler vibration shock test method for simulating in-situ stress state sand of the present invention includes the following steps:

[0052] S1. The model sand sample 18 is prepared in the model box 1 by the sand rain method, and the initial density and relative compactness of the sand in the model sand sample 18 are controlled by adjusting the height of the falling sand;

[0053] In the present embodiment, the specific process of preparing the model sand sample 18 is as follows:

[0054] First of all, if the artificially prepared model sand sample 18 is to be similar to the sand state in the actual foundation, it is necessary to control the density and initial compactness of the sand in the model sand sample 18. The model sand sample 18 was prepared by the sand-rain method, and it was found that the model sand sample 18 prepared by the sand-rain method was most similar to the in-situ sand, and the variables of the falling-sand in the s...

Embodiment 2

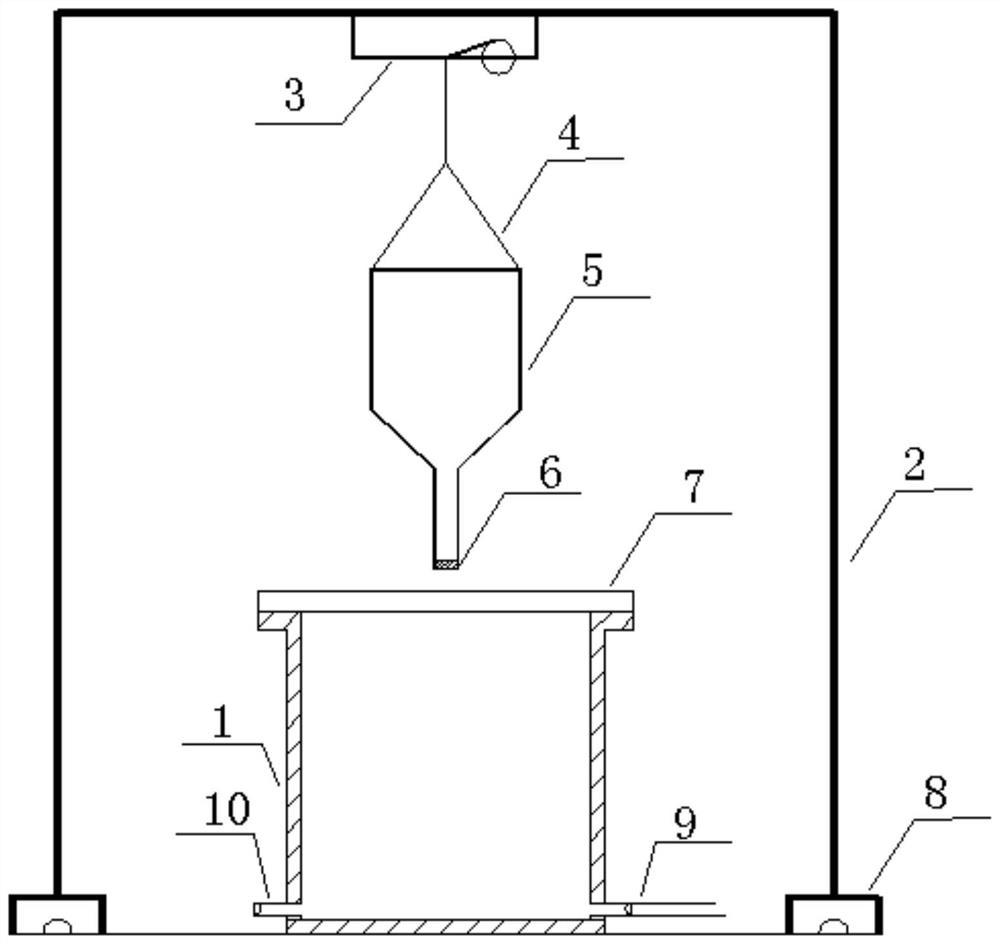

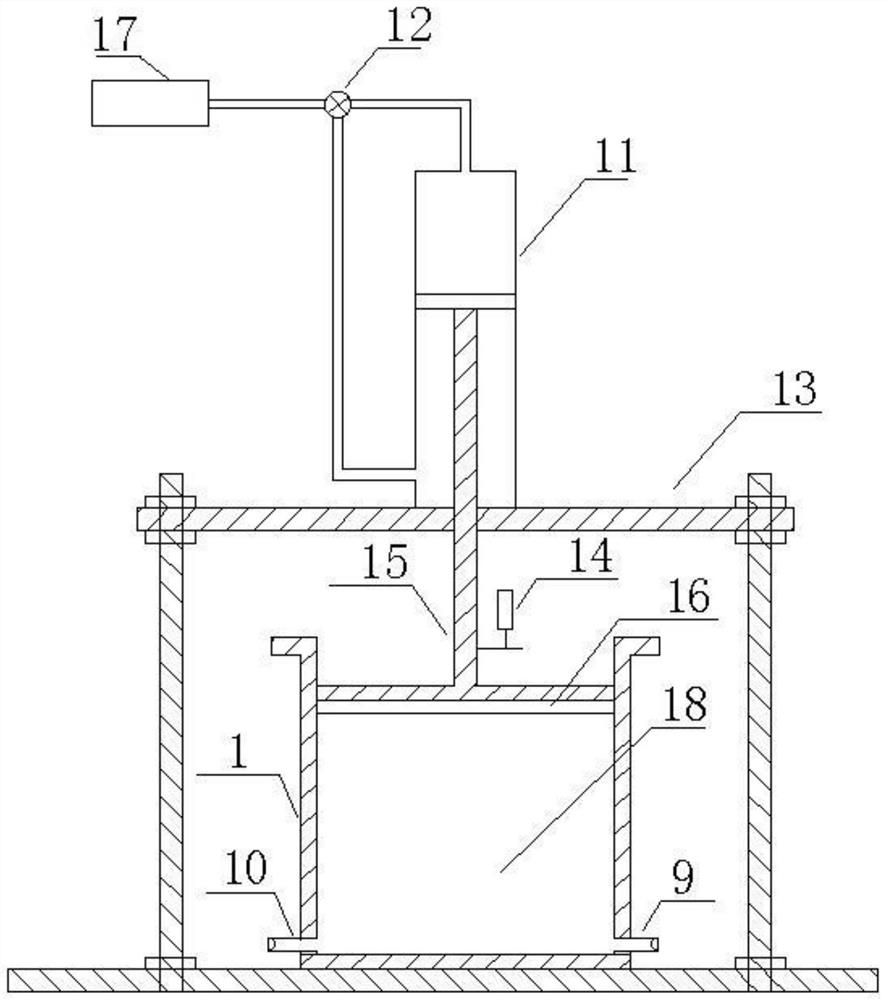

[0075] In order to complete the above test method, the present invention also provides a non-filler vibration shock test device for simulating in-situ stress state sand to realize the test method, and the test device includes:

[0076] model box 1;

[0077] Sand rain sample preparation system, preparing model sand samples 18 in the model box 1;

[0078] a vertical stress loading system, which applies vertical consolidation stress to the model sand sample 18;

[0079] The vibrator 19 applies a vibratory load to the model sand sample 18;

[0080] The vibrator coding controller 20 adjusts the penetration, pulling speed and segmented vibration retention time of the vibrator 19 in the model sand sample 18;

[0081] The saturated water tank 21 is communicated with the bottom of the model box 1, and water is injected into the model box 1 to realize the slow saturation of the model sand sample 18;

[0082] Sensor and dynamic signal test and analysis system 27, the sensor includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com