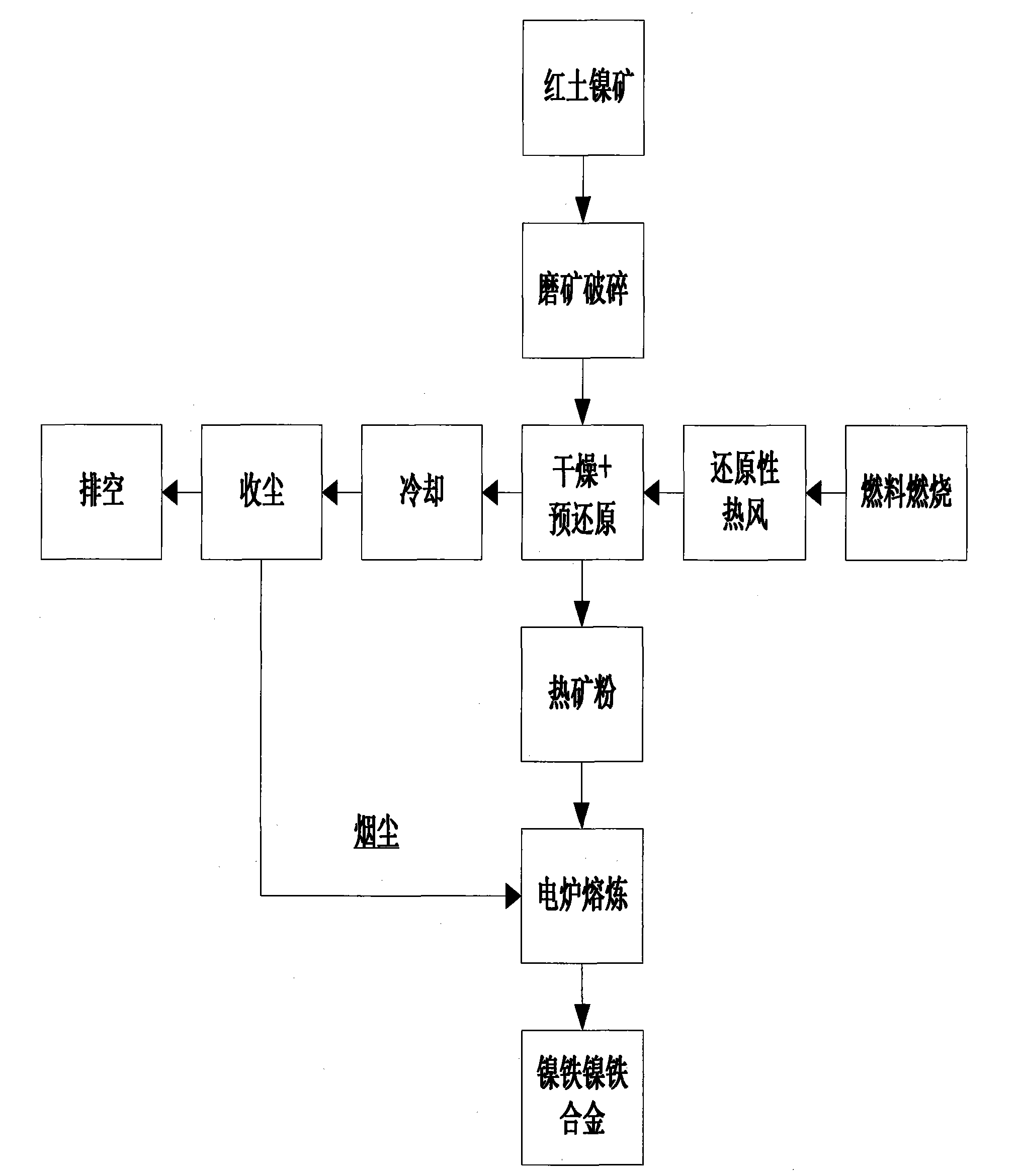

Method for fluidized drying and synchronous pre-reduction of laterite-nickel ore

A laterite nickel ore and fluidization technology, applied in the field of metallurgy, can solve the problems of high energy consumption, low efficiency, singleness, etc., and achieve the effects of improving production efficiency, shortening the process flow, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A laterite nickel ore in Yunnan was selected as the raw material. The water content of the raw ore was 26%. The raw ore was dried and vertically milled, and the laterite nickel ore powder with a particle size of less than 1mm was loaded into the third-stage reactor after drying the vertical mill. Mineral powder passes through the first-stage reactor, the second-stage reactor, and the third-stage reactor in sequence. The temperature of the first-stage reactor is 300°C, the temperature of the second-stage reactor is 500°C, and the temperature of the third-stage reactor is The temperature is 800°C, and the residence time of mineral powder in each reactor is 3-5 minutes.

[0020] The heat source of the reactor is mainly provided by the combustion chamber, which uses pulverized coal as fuel for combustion, and the reducing hot air generated first enters the third-stage reactor, then enters the second-stage reactor, and finally is discharged from the first-stage reactor. The ...

Embodiment 2

[0023] A laterite nickel ore in Yunnan was selected as the raw material. The water content of the raw ore was 29%. The raw ore was dried and vertically milled, and the laterite nickel ore powder with a particle size of less than 1mm was loaded into the fifth-stage reactor after drying the vertical mill. Mineral powder passes through the first to fifth reactors in turn. The temperature of the first reactor is 200°C, the temperature of the second reactor is 300°C, the temperature of the third reactor is 500°C, and the temperature of the fourth reactor is The temperature of the reactor is 700°C, the temperature of the fifth-stage reactor is 900°C, and the residence time of the ore powder in each stage of the reactor is 2 to 3 minutes.

[0024] The heat source of the reactor is mainly provided by the combustion chamber, which uses pulverized coal as fuel, and the reducing hot air generated first enters the fifth-stage reactor, then enters the fourth, third, and second-stage reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com