Honeycomb-ceramic-type monolithic catalyst, and preparation method and application thereof

A monolithic catalyst and honeycomb ceramic carrier technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy-to-break cordierite mechanical strength, harsh synthesis conditions, and uneven growth of molecular sieves. Achieve the effects of easy industrial application, easy control of synthesis conditions, good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

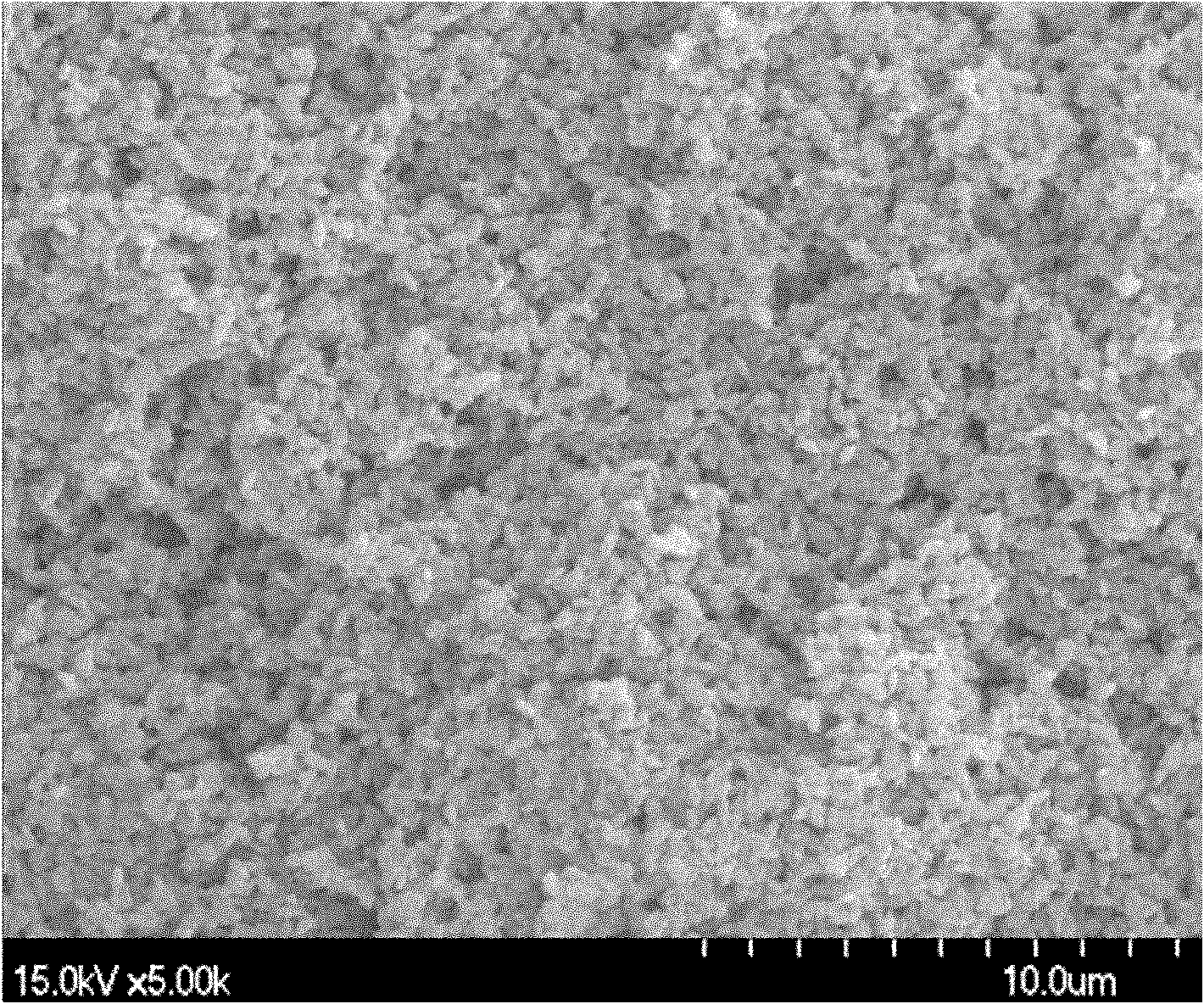

[0031] Embodiment 1 Coating of all-silicon β molecular sieve on the surface of honeycomb ceramics

[0032] Cordierite honeycomb ceramics were treated with 10% HNO at 90°C 3 The solution was treated for 2 hours, then washed with deionized water to neutrality, dried at 110°C for 8 hours, roasted at 500°C for 3 hours, then placed in an aqueous solution of tetraethylammonium hydroxide with a mass concentration of 25%, and soaked at room temperature for 4 hours to obtain a pretreated The final honeycomb ceramic carrier.

[0033] The molar ratio of each component in the all-silicon β molecular sieve synthesis liquid is template agent: silicon source: hydrogen halide: water=0.51: 1: 0.36: 13.77, the silicon source used is tetraethyl orthosilicate (TEOS), and the template agent is Tetraethylammonium hydroxide (TEAOH), the hydrogen halide is hydrogen fluoride; accurately weigh 28.27g of TEAOH, 19.67g of TEOS, 1.70g of HF and 2g of deionized water according to the molar ratio of the fe...

Embodiment 2

[0035] The treatment temperature of the cordierite honeycomb ceramic carrier in 10% nitric acid solution is 80°C, and other operations are the same as in Example 1. By comparing the quality of cordierite before and after loading, the mass ratio of all-silicon β molecular sieve to cordierite carrier is about 0.2: 1.

Embodiment 3

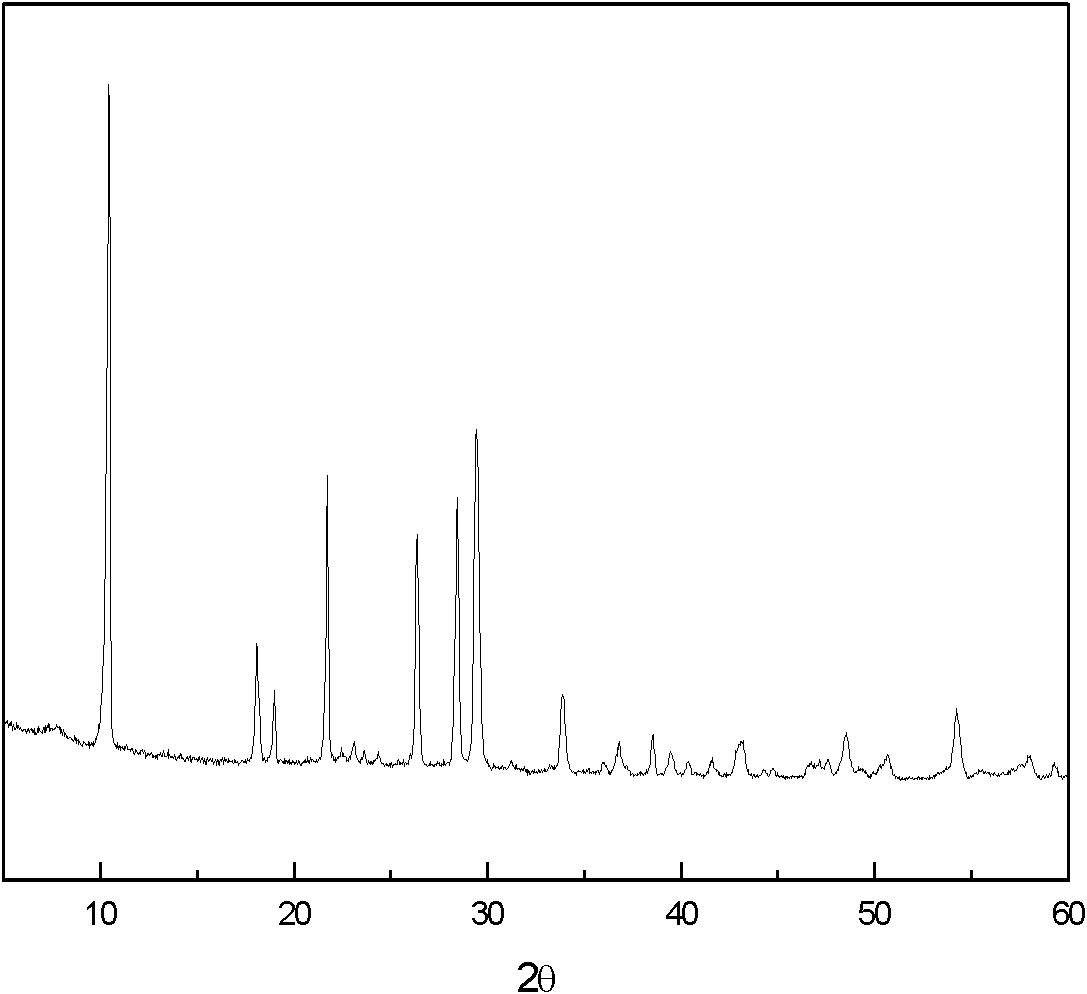

[0036] Example 3 Coating all-silicon β molecular sieves on the surface of honeycomb ceramics by in-situ synthesis

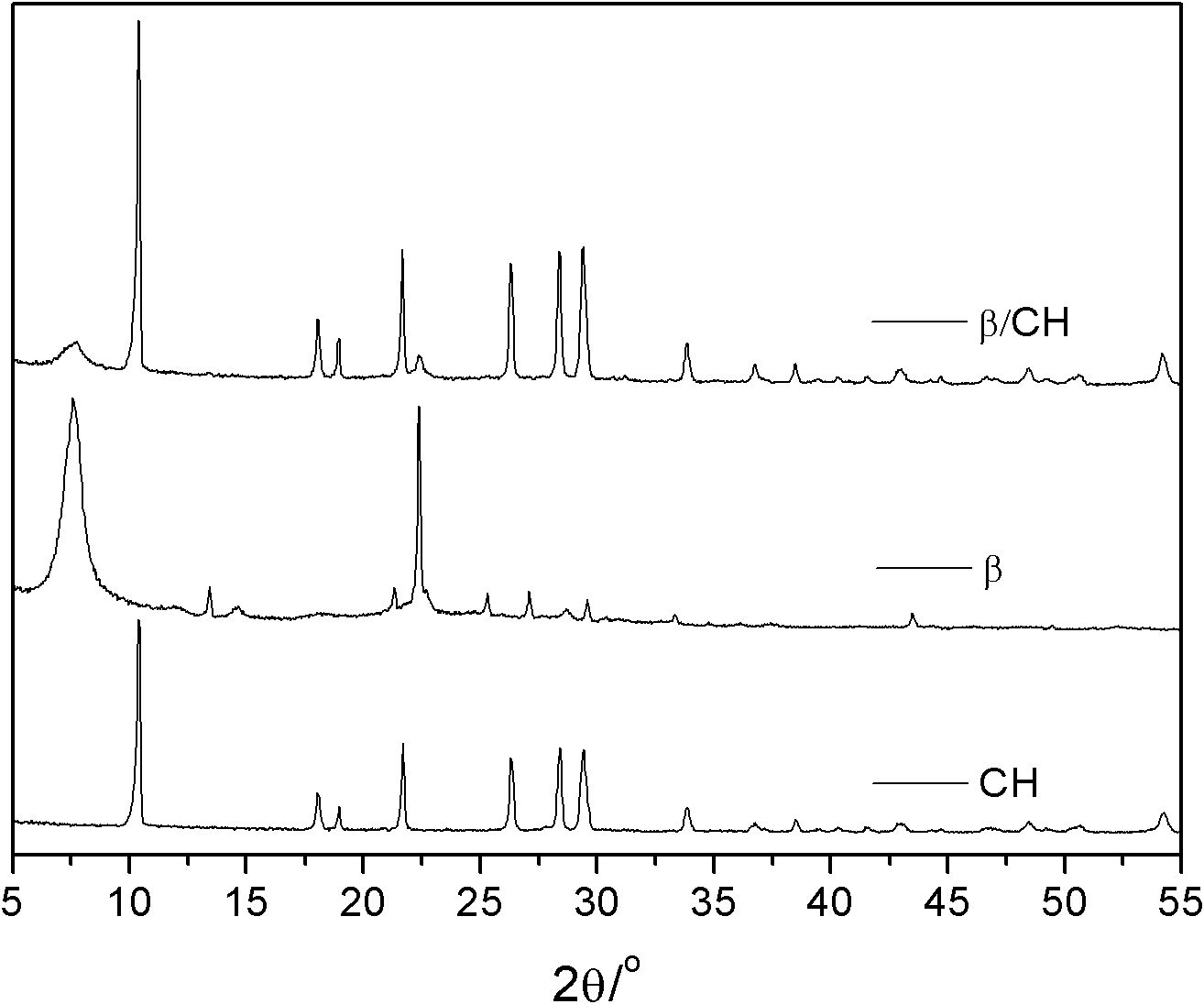

[0037] Treat the cordierite honeycomb ceramic carrier in a nitric acid solution with a mass concentration of 50% at 30°C for 10 hours, and other operations are the same as in Example 1. The XRD results show that the cordierite carrier is loaded with all-silicon β molecular sieve, and the cordierite before and after loading is compared. The mass ratio of available all-silicon β molecular sieve to cordierite carrier is about 0.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com