Method for manufacturing nitride semiconductor device

A technology of nitride semiconductors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, optical waveguide semiconductor structure, semiconductor devices, etc., can solve the problems of entering the active layer, deterioration of the active layer, deterioration of device characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

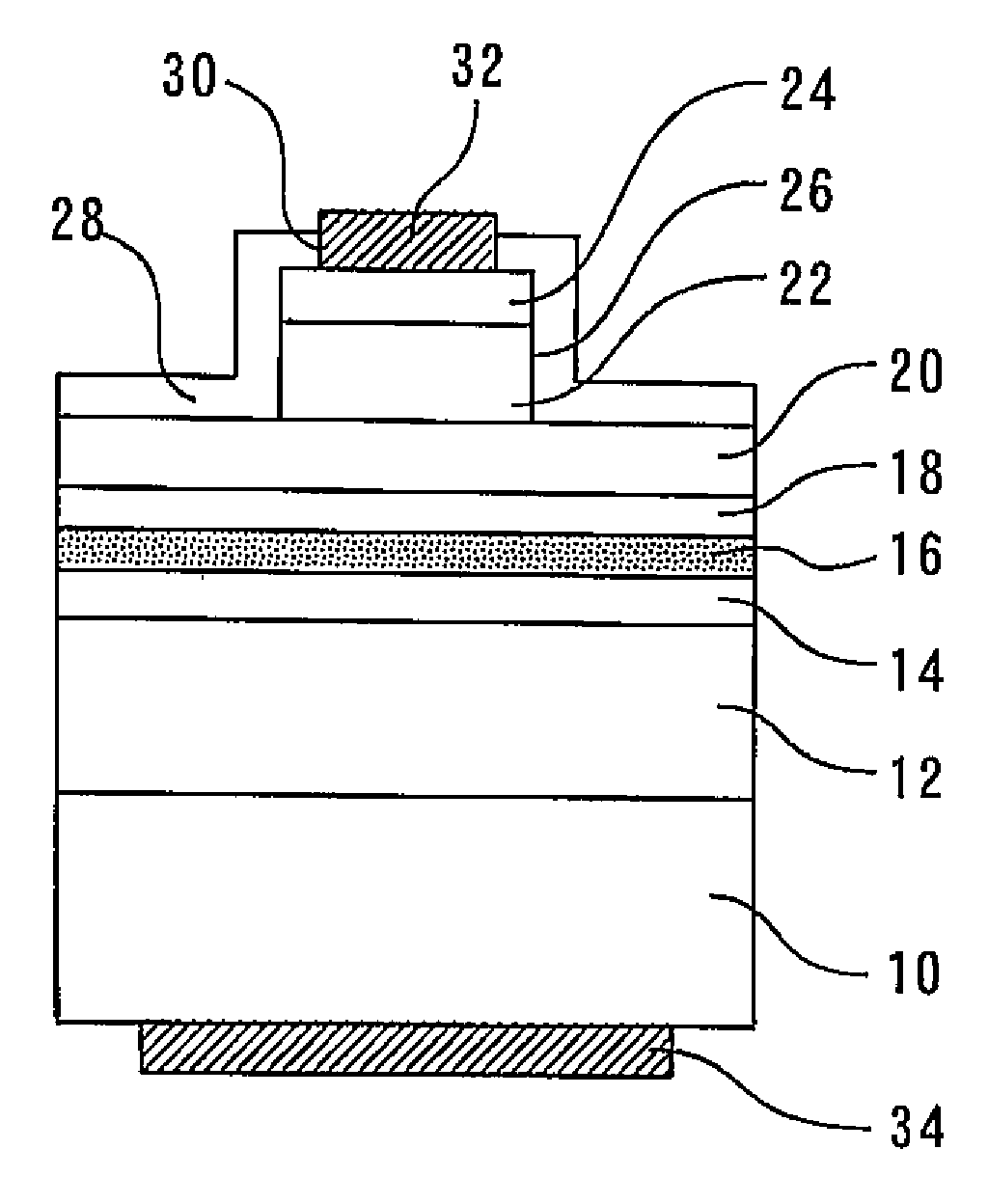

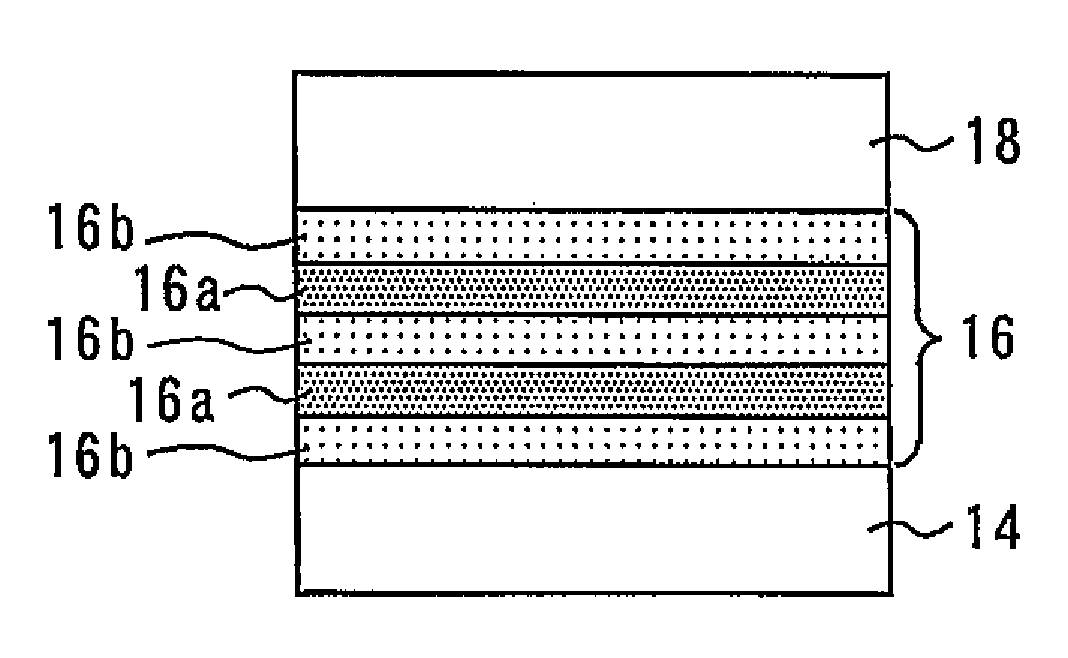

[0039] figure 1 It is a sectional view showing the nitride semiconductor device of Embodiment 1. This nitride semiconductor device is a nitride-based semiconductor laser.

[0040] On the (0001) plane which is the main surface of the n-type GaN substrate 10, n-type Al with a thickness of 2.0 μm is sequentially formed. 0.03 Ga 0.97 N cladding layer 12, n-type GaN optical guiding layer 14 with a thickness of 0.1 μm, active layer 16, p-type Al with a thickness of 0.02 μm 0.2 Ga 0.8 N electron blocking layer 18, p-type GaN optical guiding layer 20 with a thickness of 0.1 μm, and p-type Al with a thickness of 0.5 μm 0.03 Ga 0.97 An N cladding layer 22 and a p-type GaN contact layer 24 with a thickness of 0.06 μm.

[0041] p-type Al 0.03 Ga 0.97 The N cladding layer 22 and the p-type GaN contact layer 24 form a waveguide ridge 26 . The waveguide ridge 26 is formed at the center portion in the width direction of the resonator, and extends between two cleavage planes which bec...

Embodiment approach 2

[0085] Figure 8 It is a sectional view showing the nitride semiconductor device of Embodiment 2. Figure 9 will be Figure 8 An enlarged cross-sectional view of the active layer of a nitride semiconductor device. The active layer 36 is used instead of the active layer 16 of the first embodiment. Other structures are the same as those in Embodiment 1.

[0086] The active layer 36 is Al with a thickness of 3.0 nm 0.01 In 0.21 Ga 0.78 N well layer 36a and Al with a thickness of 16.0nm 0.01 In 0.015 Ga 0.975 The N barrier layers 36b are alternately laminated with two pairs of multiple quantum well structures.

[0087] A method of manufacturing the active layer 36 will be described. First, while supplying NH 3 gas while changing the temperature of n-type GaN substrate 10 to 750°C. Then, as a carrier gas, in N 2 A small amount of H is mixed in the gas 2 Gas, feed ammonia, 1,2-dimethylhydrazine, TMG, TMI, TMA, form Al 0.01 In 0.21 Ga 0.78 N well layer 36a and Al 0....

Embodiment approach 3

[0090] Figure 10 It is a cross-sectional view showing a nitride semiconductor device according to Embodiment 3. Figure 11 will be Figure 10 An enlarged cross-sectional view of the active layer of a nitride semiconductor device. The active layer 38 is used instead of the active layer 16 of the first embodiment. Other structures are the same as those in Embodiment 1.

[0091] The active layer 38 is In with a thickness of 3.0 nm 0.2 Ga 0.8 N well layer 38a and Al with a thickness of 16.0nm 0.03 In 0.002 Ga 0.968 N barrier layers 38b are alternately laminated with two pairs of multiple quantum well structures.

[0092] A method of manufacturing the active layer 38 will be described. First, while supplying NH 3 gas while changing the temperature of n-type GaN substrate 10 to 750°C. Then, as a carrier gas, in N 2 A small amount of H is mixed in the gas 2 Gas, supply ammonia, 1,2-dimethylhydrazine, TMG, TMI, form In 0.2 Ga 0.8 N well layer 38a. Then, feed ammonia, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com