Apparatus and method for winding electrode assembly

A winding device and assembly technology, applied in battery electrodes, winding/folding electrodes, circuits, etc., can solve the problems of inability to wind the winding part 400, detachment, idling of the winding part 400, etc., to improve work efficiency and production performance, The effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

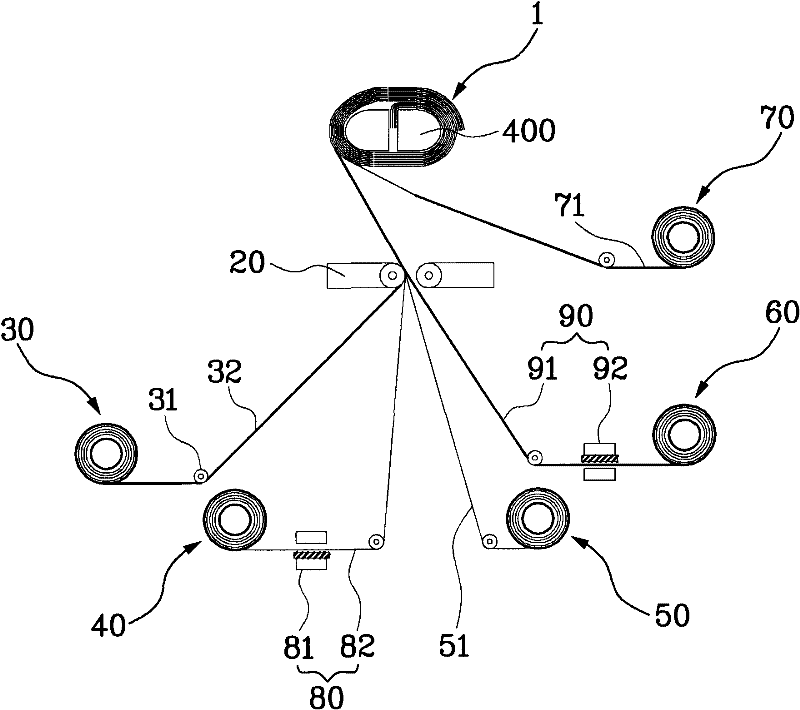

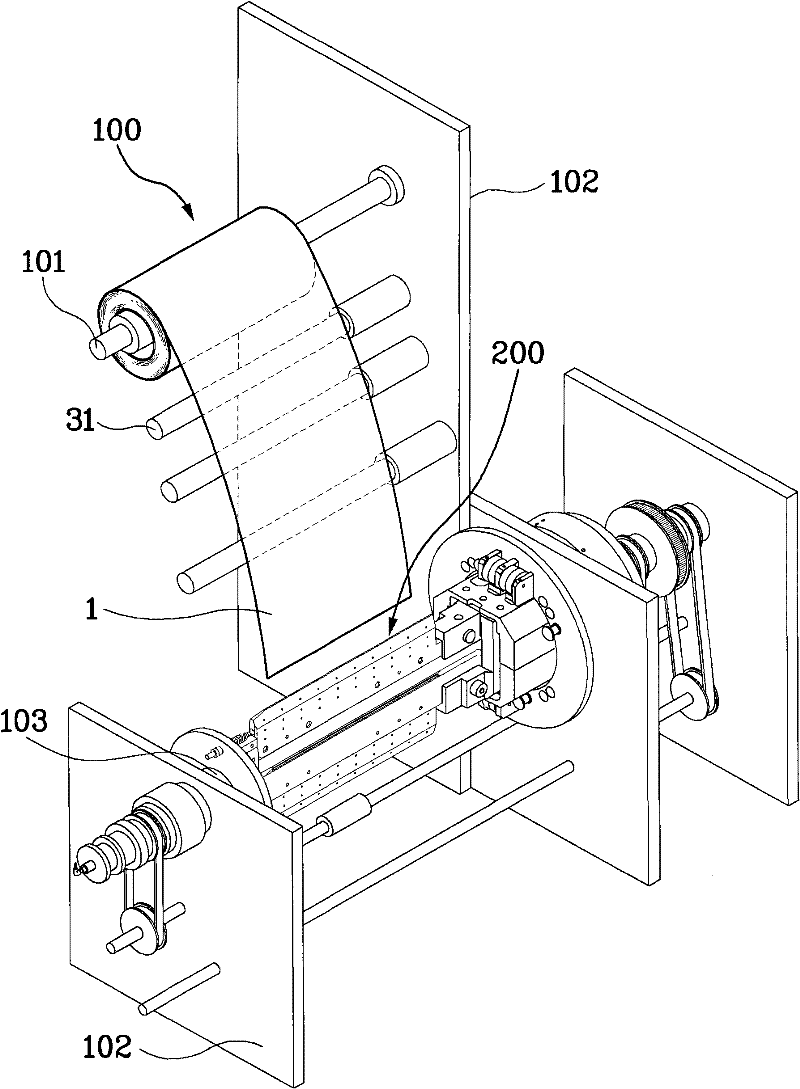

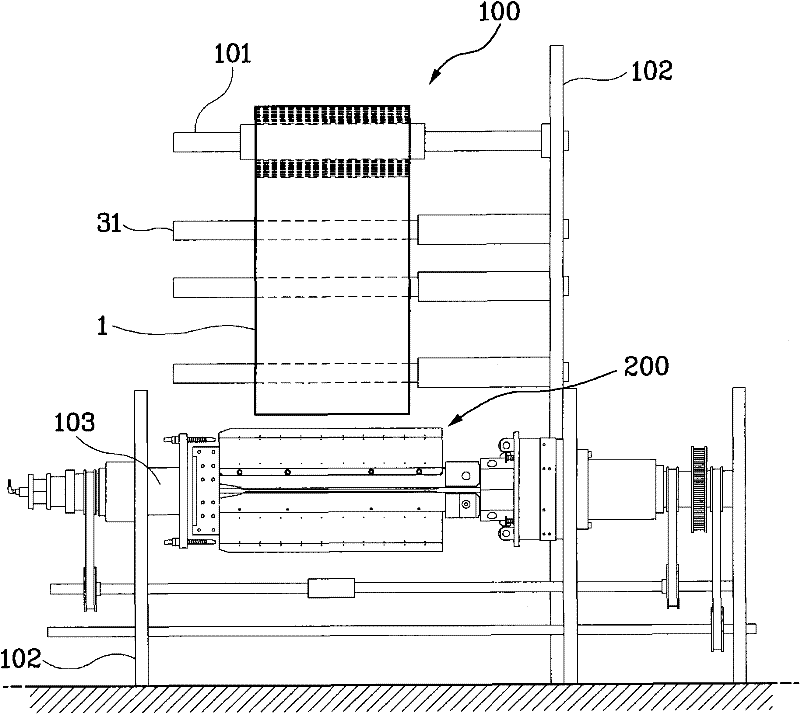

[0059] figure 2 and image 3 It is a perspective view and a front view of the electrode assembly winding device of the present invention, Figure 4 is a perspective view of the winder in the electrode assembly winding device of the present invention, Figure 5 It is the front view of the winder in the electrode assembly drawing winding device of the present invention, Figure 6 yes Figure 5 Partial detailed exploded view of the 1st and 2nd clamps and the 1st and 2nd winding rollers of the 1st and 2nd clamps, corresponding to and showing the existing structure figure 1 Repeated identical structural elements use the same reference numerals and describe the present invention.

[0060] Referring to the drawings, the electrode assembly winding device of the present invention includes a feeder 100 for supplying an electrode assembly 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com