White LED chip and forming method thereof

A LED chip, white technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of angle change, complex control circuit, unstable color temperature, etc., and achieve the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

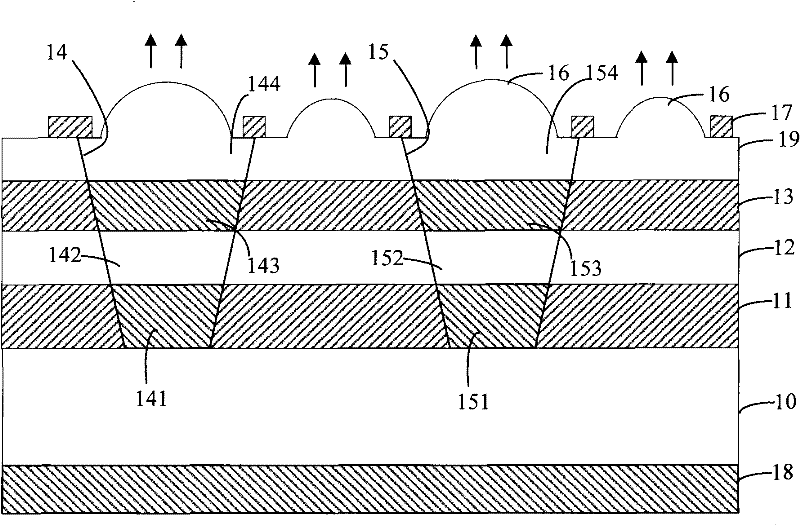

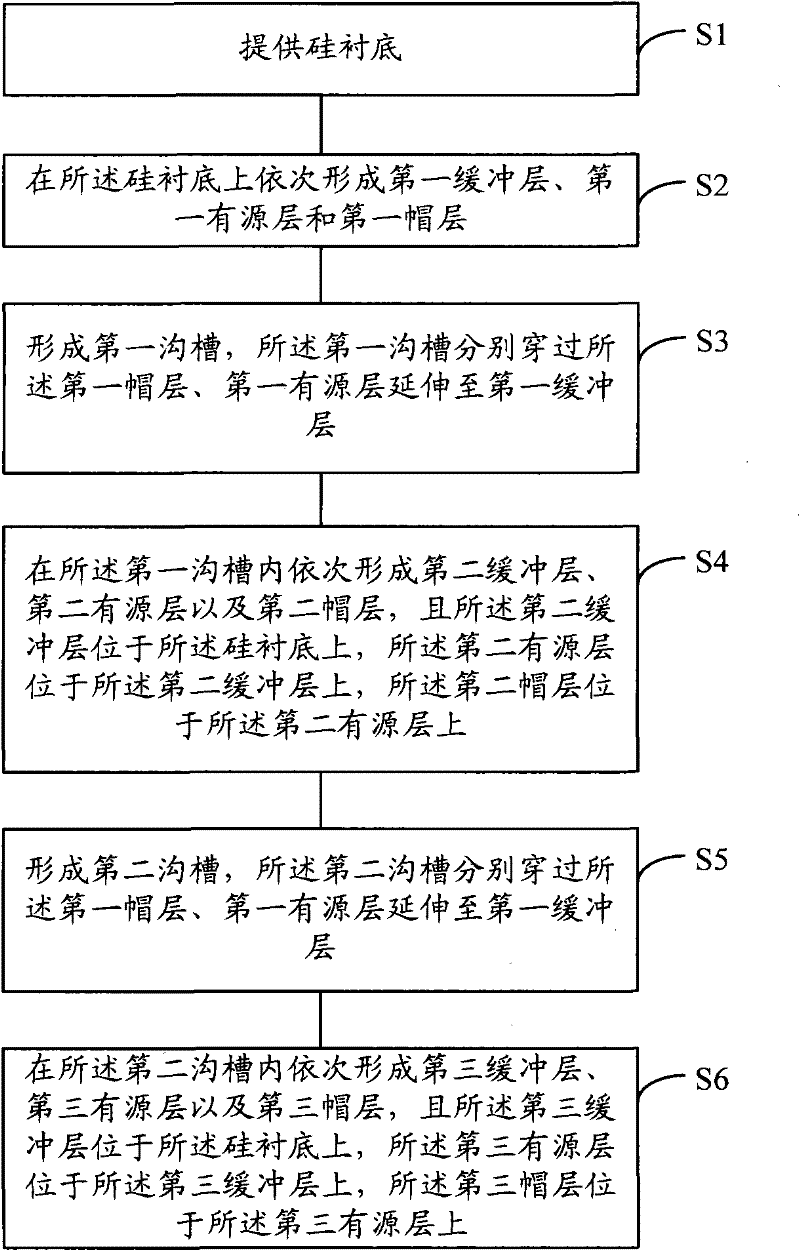

[0070] In the white LED chip and its forming method according to the specific embodiment of the present invention, by forming the first groove and the second groove in the single-color LED chip, the other two kinds of monochromatic LED chips are respectively formed in the first groove and the second groove. When controlling the LED chip to emit light, one LED chip can simultaneously emit three colors of red, green and blue light. After the three colors of light are mixed, it can emit white light, and because it is the control of the same chip, it can be controlled Simple. Moreover, using a silicon substrate whose crystal orientation deviates from 1 to 9° along the (111) crystal plane, and growing a buffer layer on the silicon substrate with the crystal orientation direction, the dislocation between the buffer layer and the silicon substrate can be reduced , reduce the peeling phenomenon between the silicon substrate and the buffer layer, thereby improving the service life of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com