Oil pressure sealing type chain tightener

A sealed and tensioner technology, applied in the direction of belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of small output, unusable, easy chain deviation, etc., to reduce sliding resistance and smooth adjustment , Good oil pressure damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

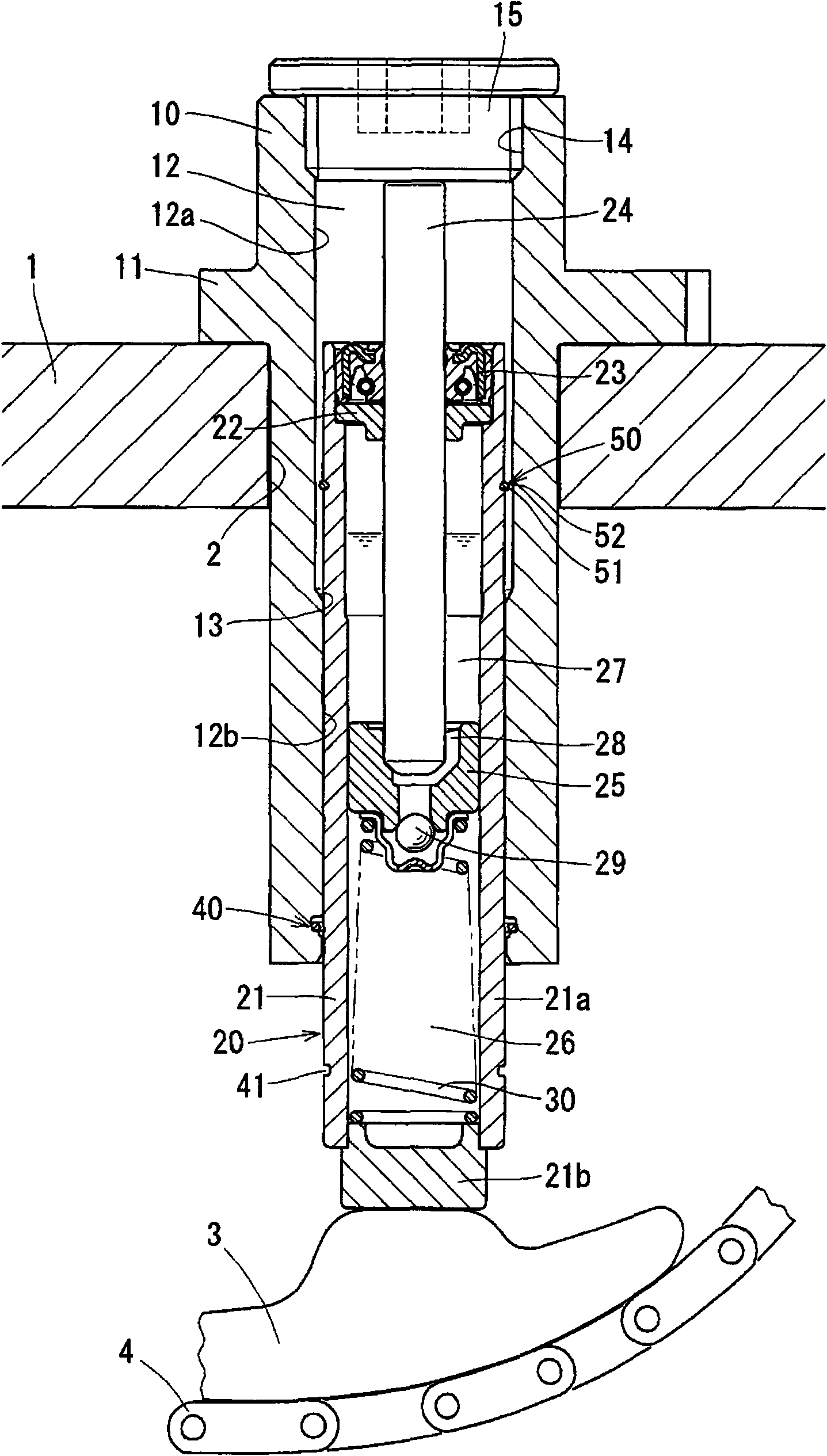

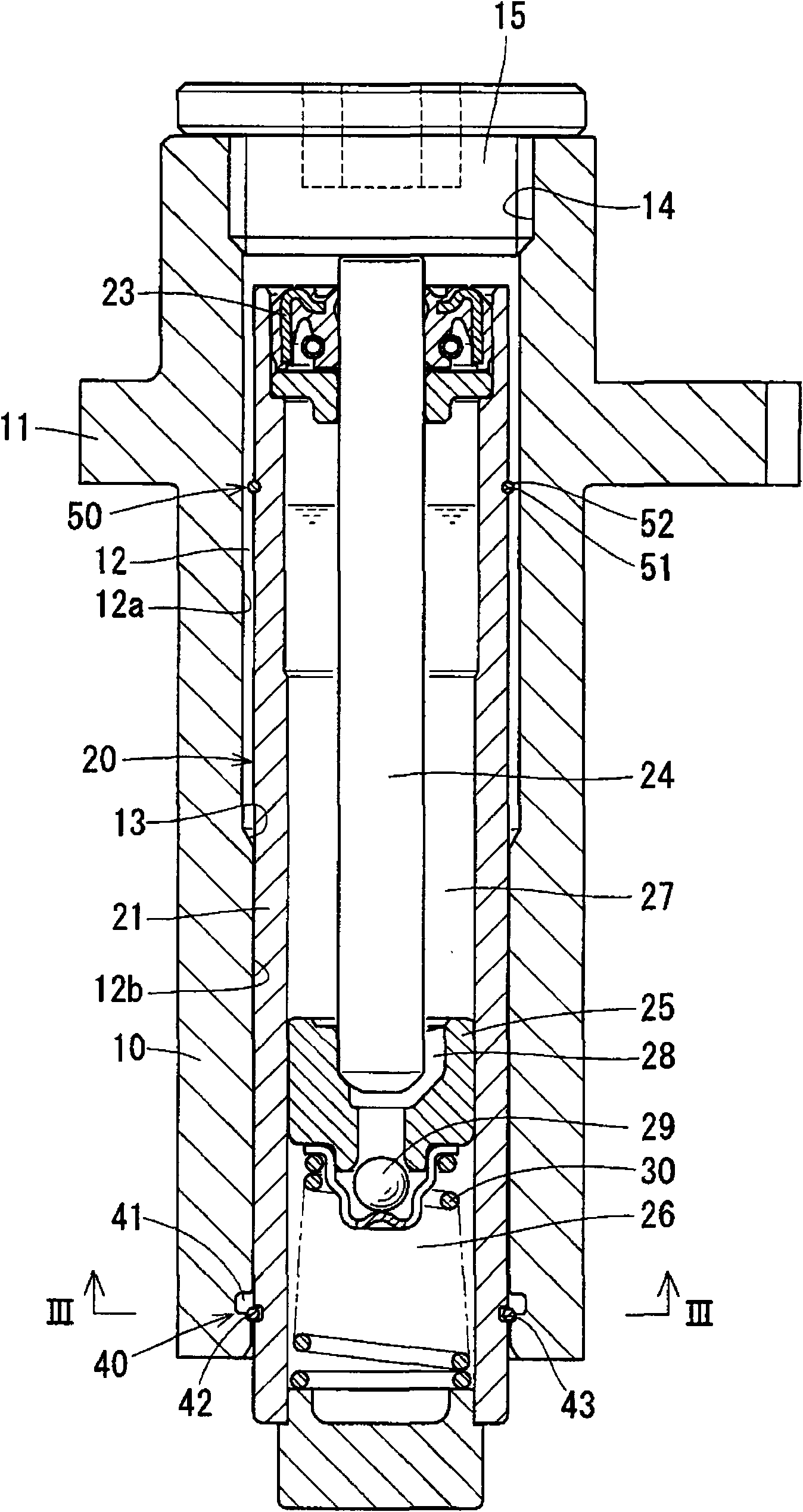

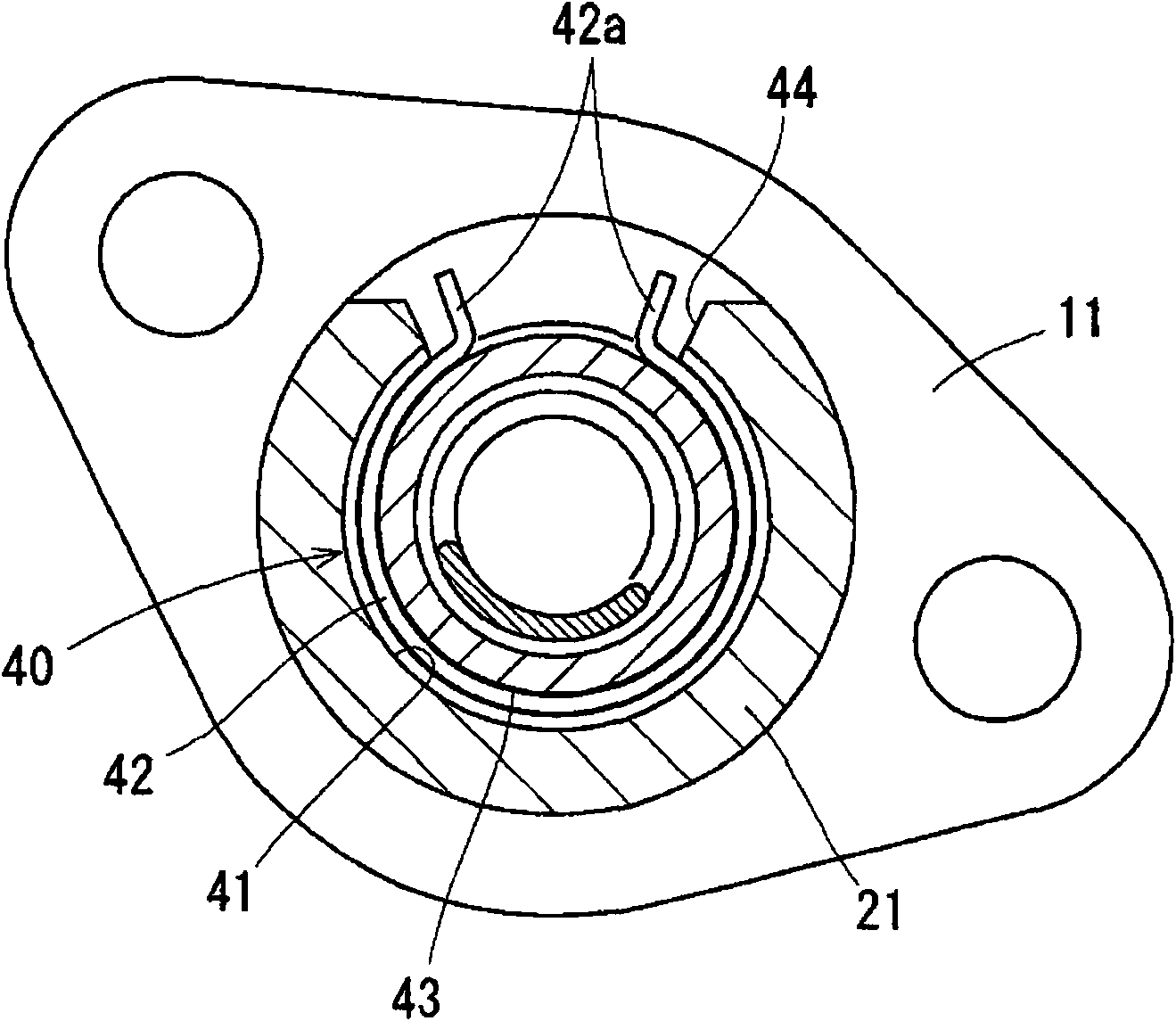

[0034] Embodiments of the present invention will be described below with reference to the drawings. Such as figure 1 As shown, the hydraulically sealed chain tensioner of the present invention is composed of a housing 10 mounted on a chain cover 1 of an engine, and a hydraulically sealed tensioner unit 20 slidably supported on the housing 10 .

[0035] The housing 10 has a cylindrical shape and can be inserted from the outside into the tensioner mounting hole 2 formed on the upper portion of the outer peripheral wall of the chain cover 1, and a flange 11 is provided on the outer circumference of the rear end portion in the insertion direction. 11 abuts against the outer surface of the chain cover 1 and is fixed by bolts.

[0036] In addition, a guide hole 12 is formed in the housing 10 , and the guide hole 12 penetrates vertically in the mounted state to the chain cover 1 . The guide hole 12 is a stepped hole in which the small-diameter hole portion 12b is formed below the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com